Compound inhibitor for exploitation of oil-gas field and preparation method thereof

A composite corrosion inhibitor, oil and gas field technology, applied in the direction of earthwork drilling, wellbore/well components, etc., can solve the problems of aggravated corrosion speed, loss of corrosion inhibitor effectiveness, large dosage, etc., to achieve protection and prevent corrosion , kill and inhibit the growth of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

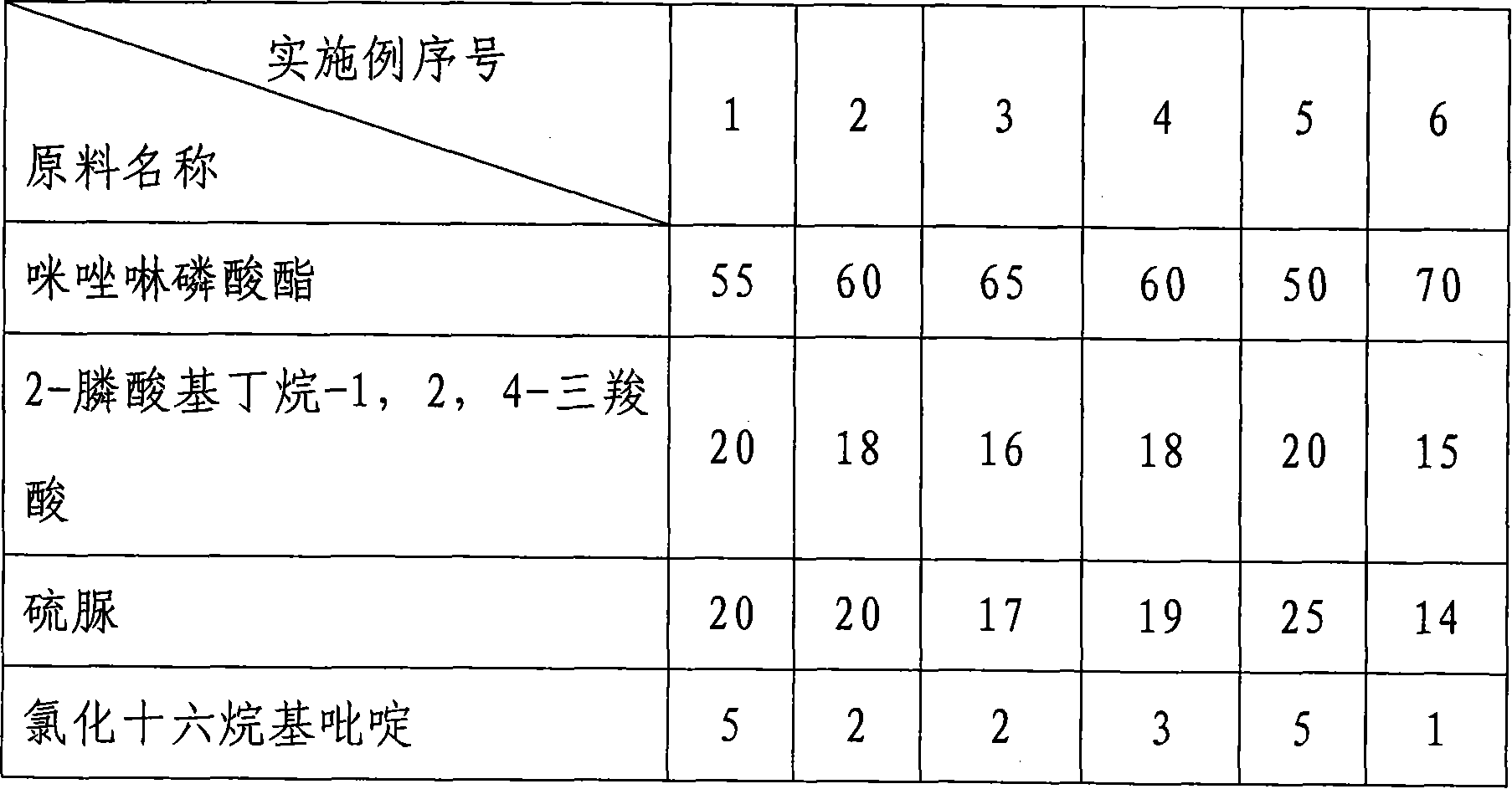

[0024] A composite corrosion inhibitor for oil and gas field development of the present invention, the preparation component (serial number 1) is added in parts by weight: 55 parts of imidazoline phosphate, 20 parts of 2-phosphonobutane-1,2,4-tricarboxylic acid , 20 parts of thiourea, and 5 parts of cetylpyridinium chloride.

Embodiment 2

[0026] The oil and gas field development uses a composite corrosion inhibitor, and the preparation component (No. 4) is added in parts by weight: 60 parts of imidazoline phosphate, 18 parts of 2-phosphonobutane-1,2,4-tricarboxylic acid, Prepared with 19 parts of thiourea and 3 parts of cetylpyridinium chloride.

Embodiment 3

[0028] The oil and gas field development uses a composite corrosion inhibitor, and the preparation component (serial number 5) is added in parts by weight: 50 parts of imidazoline phosphate, 20 parts of 2-phosphonobutane-1,2,4-tricarboxylic acid, Prepare 25 parts of thiourea and 5 parts of cetylpyridinium chloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com