Discontinuous double oblique crossing rib strengthened heat exchange method between flat-plates

A technology of strengthening heat exchange and plate heat exchanger, which is applied in indirect heat exchangers, heat exchanger types, fixed plate conduit components, etc., can solve the problems of strengthening heat exchange and increasing flow resistance at the same time, and achieve good anti-fouling effect. , The effect of strengthening heat transfer is remarkable, and the molding is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

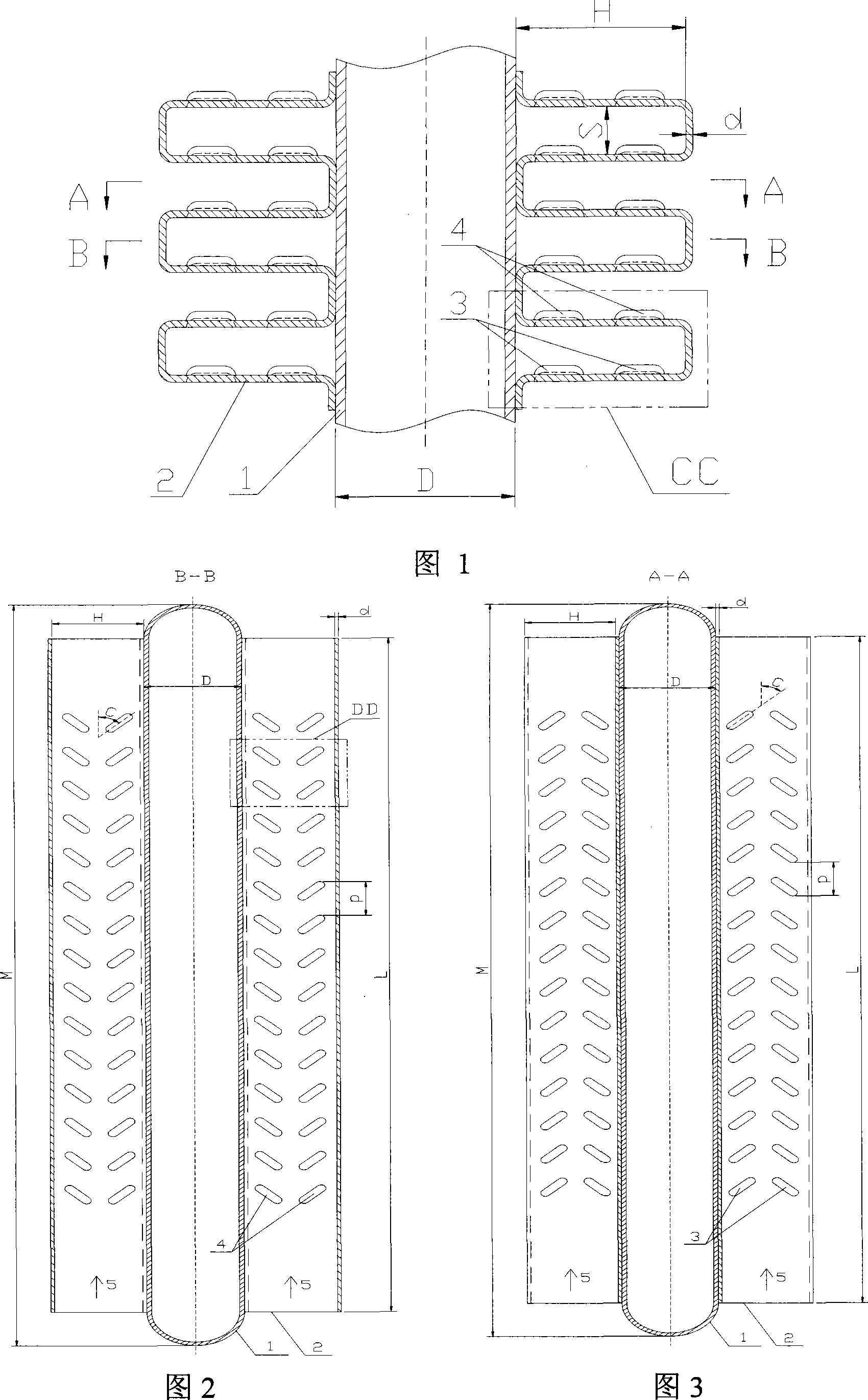

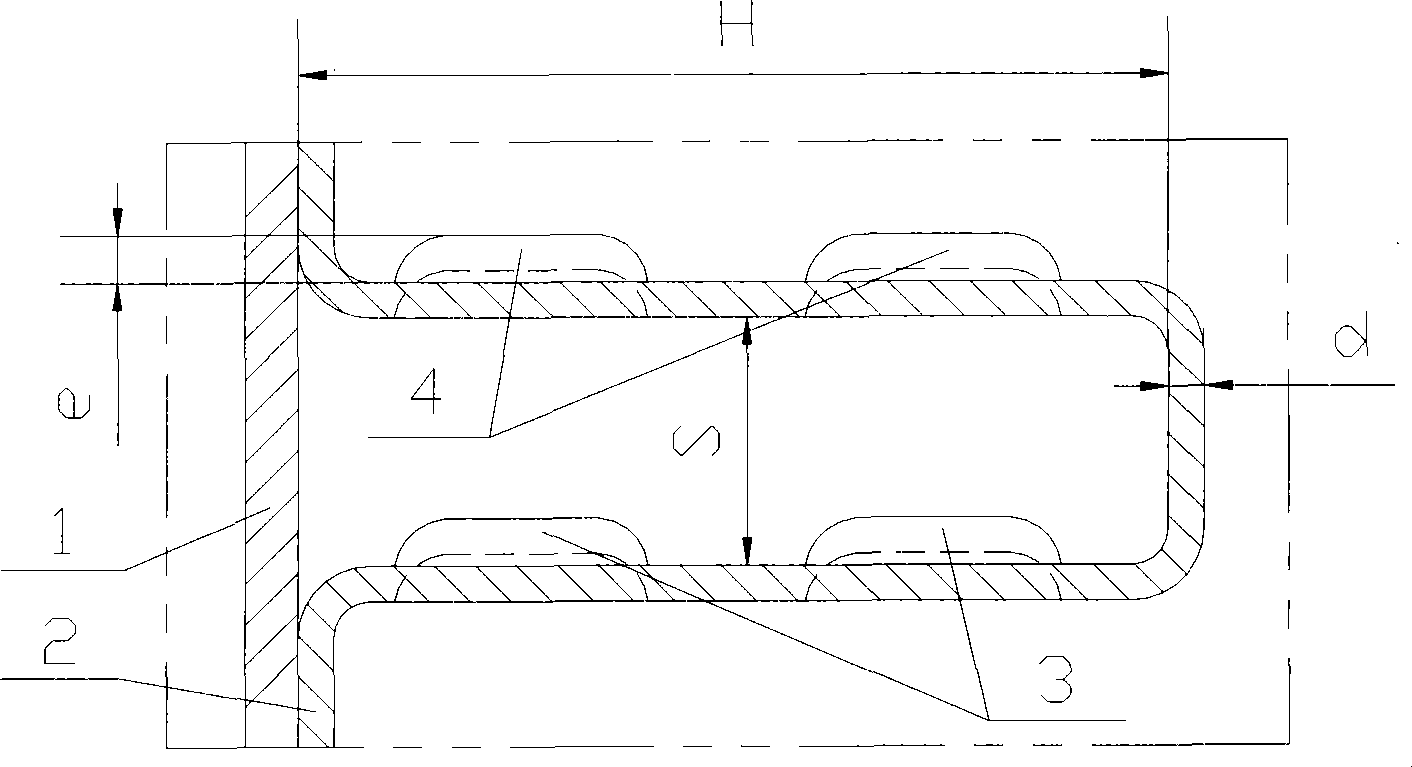

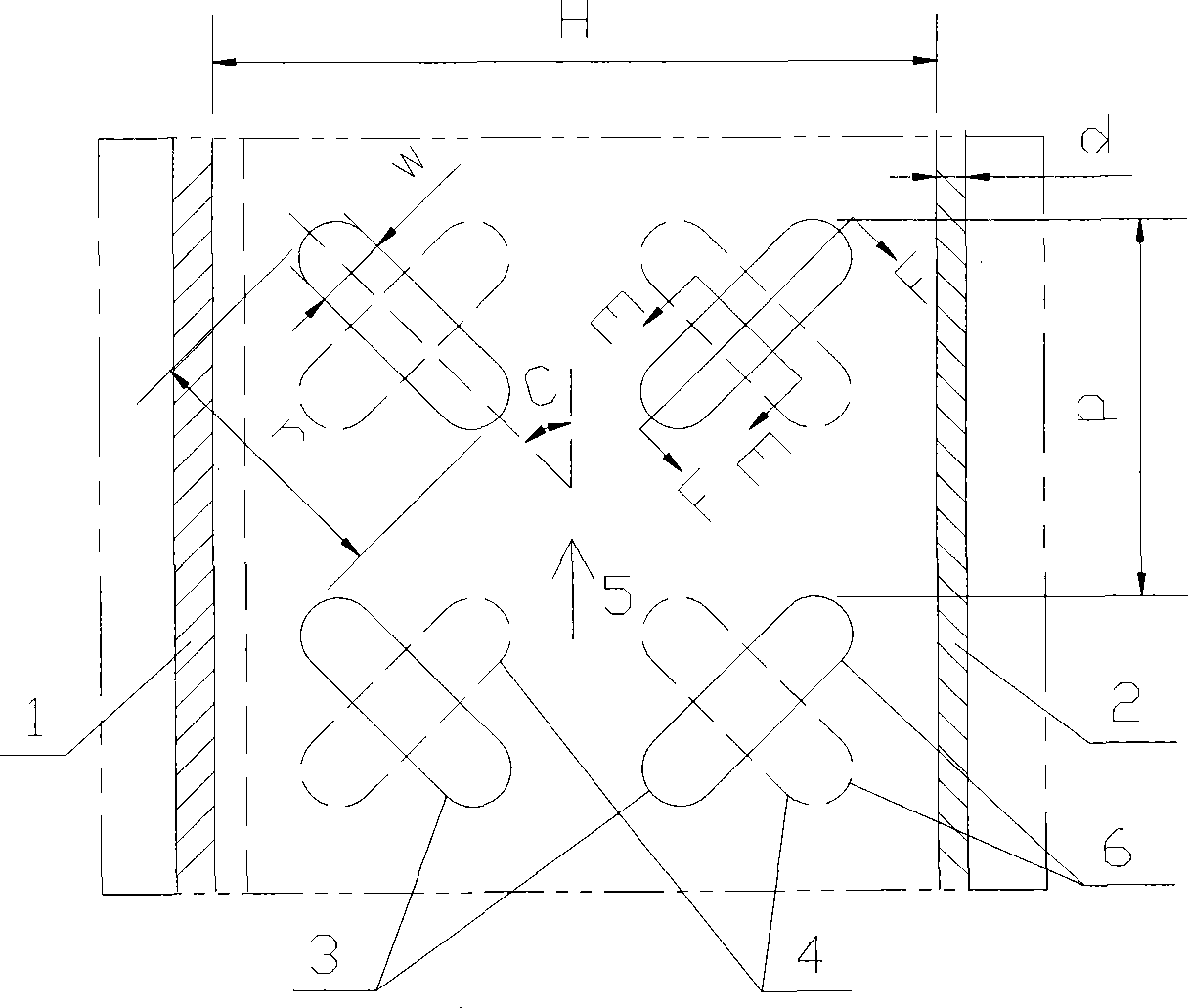

[0024] According to the field synergy theory of convective heat transfer, the multi-longitudinal vortex has excellent flow characteristics and enhanced heat transfer, especially in laminar flow and low Reynolds number of Re≤10000, its comprehensive enhanced heat transfer performance is more prominent. The fin spacing of finned tubes is generally relatively small, and the Reynolds number of the flow between the fins is generally less than 2000; due to the compactness of the plate heat exchanger, the channel between the plates is relatively narrow, so the Reynolds number of the flow between the plates of the plate heat exchanger is generally Less than 10000. Therefore, the inter-fin heat transfer of finned tubes and the inter-plate heat transfer of plate heat exchangers belong to low Reynolds number convective heat transfer. The discontinuous double oblique intersecting ribs between the flat plates of the present invention can generate multiple longitudinal vortices in the fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com