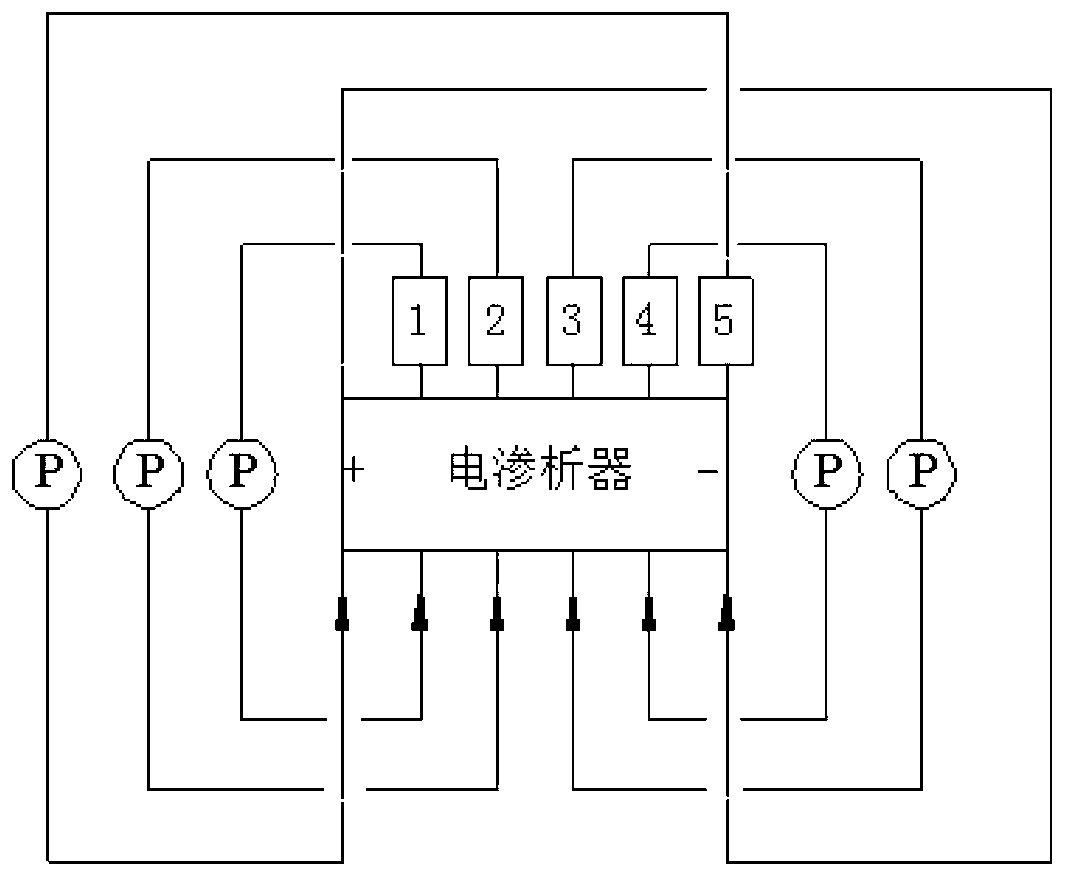

Preparation technology of hypophosphorous acid with five-room electrodialysis method

An electrodialysis method, electrodialysis technology, applied in the field of hypophosphorous acid preparation by five-chamber electrodialysis method, can solve the problems of low efficiency and high energy consumption, and achieve the effects of high efficiency, low energy consumption and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

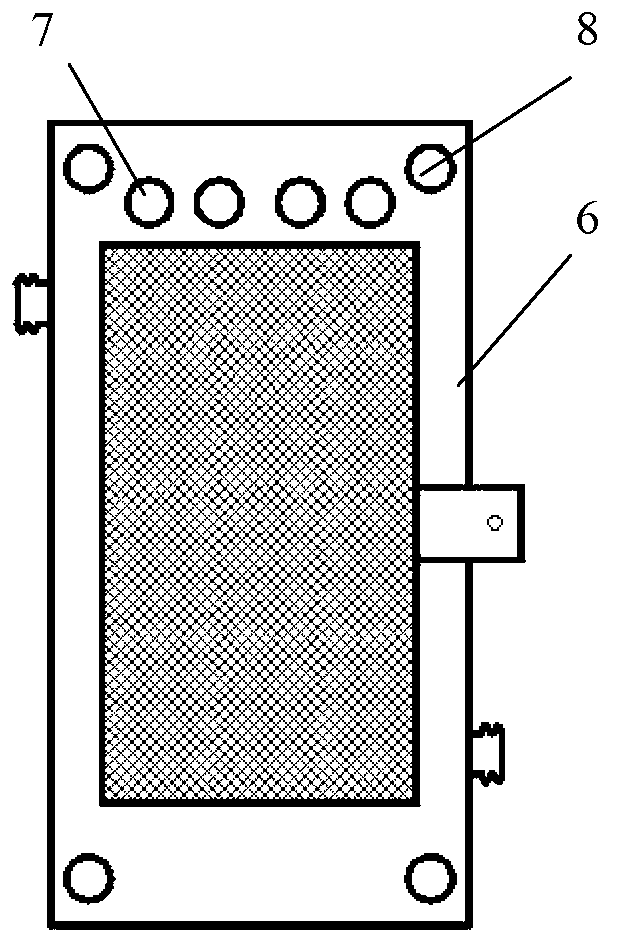

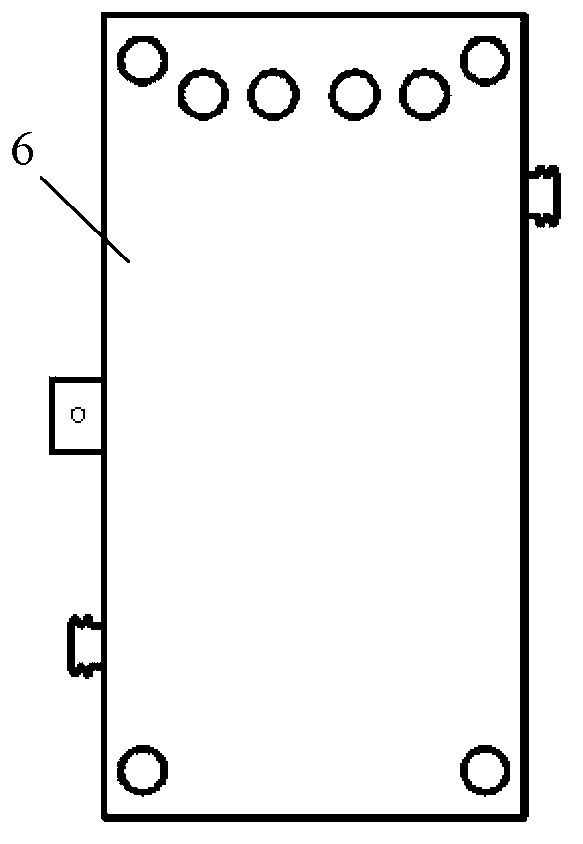

[0035]The electrode plate material is made of high-quality titanium as the base material, and the surface is coated with rare metal ruthenium, and the electrode area is 20000cm 2 . The solution volume of each chamber of the five-chamber electrodialysis device is 2000 mL. The initial solution concentration of the electrode chamber is 10g / L sulfuric acid aqueous solution. The mass ratio to sodium hypophosphite monohydrate crystals is 0.5:1.

[0036] Using the above electrodialysis device, its working voltage is DC 9V, the liquid flow rate of each chamber is 300L / h, the total flow rate is 1500L / h, and the electrodialysis time is 3h. After the start of operation, samples were taken at intervals to measure the pH changes in the samples in each chamber. The standard for the completion of electrodialysis was that the current flowing through the electrodialyzer began to drop significantly. The test results are shown in Table 1.

[0037] Table 1 Product chamber pH and current as a ...

Embodiment 2

[0041] The electrode material is made of high-quality titanium as the base material, and the surface is coated with rare metal ruthenium, and the electrode area is 20000cm 2 . The solution volume in each chamber of the five-chamber electrodialyzer was 2000 mL. The initial solution concentration of the electrode chamber is 10g / L of dilute sulfuric acid solution. The mass ratio with sodium hypophosphite crystal is 0.6:1.

[0042] The above electrodialysis device was used, its working voltage was DC 9V, the liquid flow rate of each chamber was 300L / h, and the electrodialysis time was 2h. After the start of operation, samples were taken at intervals to measure the pH changes in the samples in each chamber. The standard for the completion of electrodialysis was that the current flowing through the electrodialyzer began to drop significantly.

Embodiment 3

[0044] The electrode material is made of high-quality titanium as the base material, and the surface is coated with rare metal ruthenium, and the electrode area is 20000cm 2 . The solution volume in each chamber of the five-chamber electrodialyzer was 2000 mL. The initial solution concentration of the electrode chamber is 10g / L sulfuric acid, the sodium sulfate chamber and the hypophosphorous acid chamber are both double distilled water, the sodium hypophosphite chamber is 51.9g / L sodium hypophosphite solution, the sulfuric acid chamber is 25g / L sulfuric acid, sulfuric acid and monohydrate The mass ratio of sodium hypophosphite crystals is 0.4:1.

[0045] The above electrodialysis device was used, its working voltage was DC 9V, the liquid flow rate of each chamber was 300L / h, and the electrodialysis time was 2h. After the start of operation, samples were taken at intervals to measure the pH changes in the samples in each chamber. The standard for the completion of electrodia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com