Titanium beneficiation method from titaniferous blast furnace slag

A blast furnace slag enrichment technology, which is applied in the direction of improving process efficiency, can solve problems such as separation difficulties, and achieve the effects of simple process, easy separation and utilization, and high grade titanium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

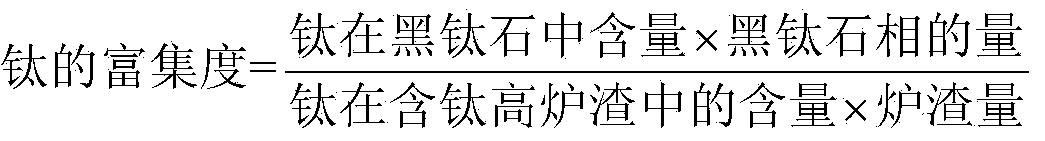

[0018] The implementation of the present invention is Panzhihua Iron and Steel's actual titanium-containing blast furnace slag, whose components are: 27.73%CaO, 26.36%SiO 2 , 14.41%Al 2 o 3 , 8.31%MgO, 22.50%TiO 2 , 0.25%V 2 o 5 , 0.44%S. Add 2.5% slag weight of B 2 o 3 , under a reducing atmosphere (the sample is placed in a graphite crucible with a graphite cover, and the outer furnace tube of the crucible is protected by high-purity argon gas), melted at 1360°C for 20min, and then cooled to 1320°C at a cooling rate of 0.25°C / min After heat preservation for 360 minutes, after quenching and solidification in ice water, the slag sample was ground, polished and carbon-sprayed. According to the analysis of scanning electron microscope and electron probe, the enrichment degree of titanium reached 29.5%, and the grade of titanium in black titanite was 88.6%.

Embodiment 2

[0020] The implementation of the present invention is Panzhihua Iron and Steel's actual titanium-containing blast furnace slag, whose components are: 27.73%CaO, 26.36%SiO 2 , 14.41%Al 2 o 3 , 8.31%MgO, 22.50%TiO 2 , 0.25%V 2 o 5 , 0.44%S. Add 1.5% slag weight of B 2 o 3 , under a reducing atmosphere (the sample is placed in a graphite crucible with a graphite cover, and the outer furnace tube of the crucible is protected by high-purity argon gas), melted at 1360°C for 20min, and then cooled to 1320°C at a cooling rate of 0.25°C / min After heat preservation for 360 minutes, after quenching and solidification in ice water, the slag sample was ground, polished and carbon-sprayed. According to the analysis of scanning electron microscope and electron probe, the enrichment degree of titanium reached 23.5%, and the grade of titanium in black titanite was 87.7%.

Embodiment 3

[0022] The implementation of the present invention is Panzhihua Iron and Steel's actual titanium-containing blast furnace slag, whose components are: 27.73%CaO, 26.36%SiO 2 , 14.41%Al 2 o 3 , 8.31%MgO, 22.50%TiO 2 , 0.25%V 2 o 5 , 0.44%S. Add 1.5% slag weight of B 2 o 3 , under a reducing atmosphere (the sample is placed in a graphite crucible with a graphite cover, and the outer furnace tube of the crucible is protected by high-purity argon gas), melted at 1360 ° C for 20 minutes, and then cooled to 1200 ° C at a cooling rate of 1 ° C / min After 60 minutes of heat preservation, after quenching and solidification in ice water, the slag sample was ground, polished and carbon-sprayed. According to the analysis of scanning electron microscope and electron probe, the enrichment degree of titanium reached 31.5%, and the grade of titanium in black titanite was 91.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com