Preparation method for in-situ modified expansion type fire retardant

A technology of intumescent flame retardants and in-situ modifiers, which is applied in the field of preparation of chemical additives, can solve the problems of slightly acidic, and the comprehensive performance of flame retardants needs to be further improved, and achieve low smoke density and reduce additives The effect of increasing the flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

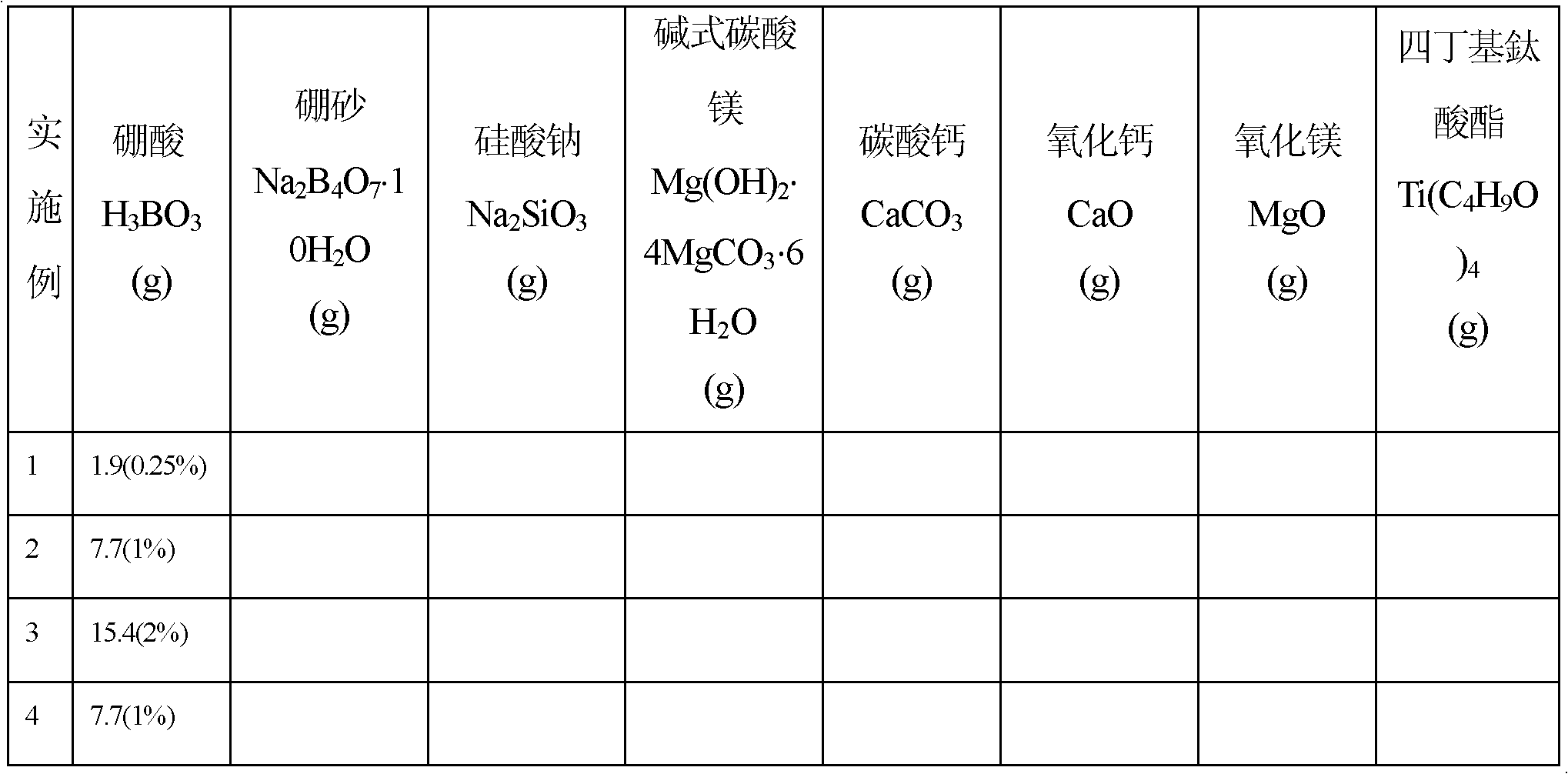

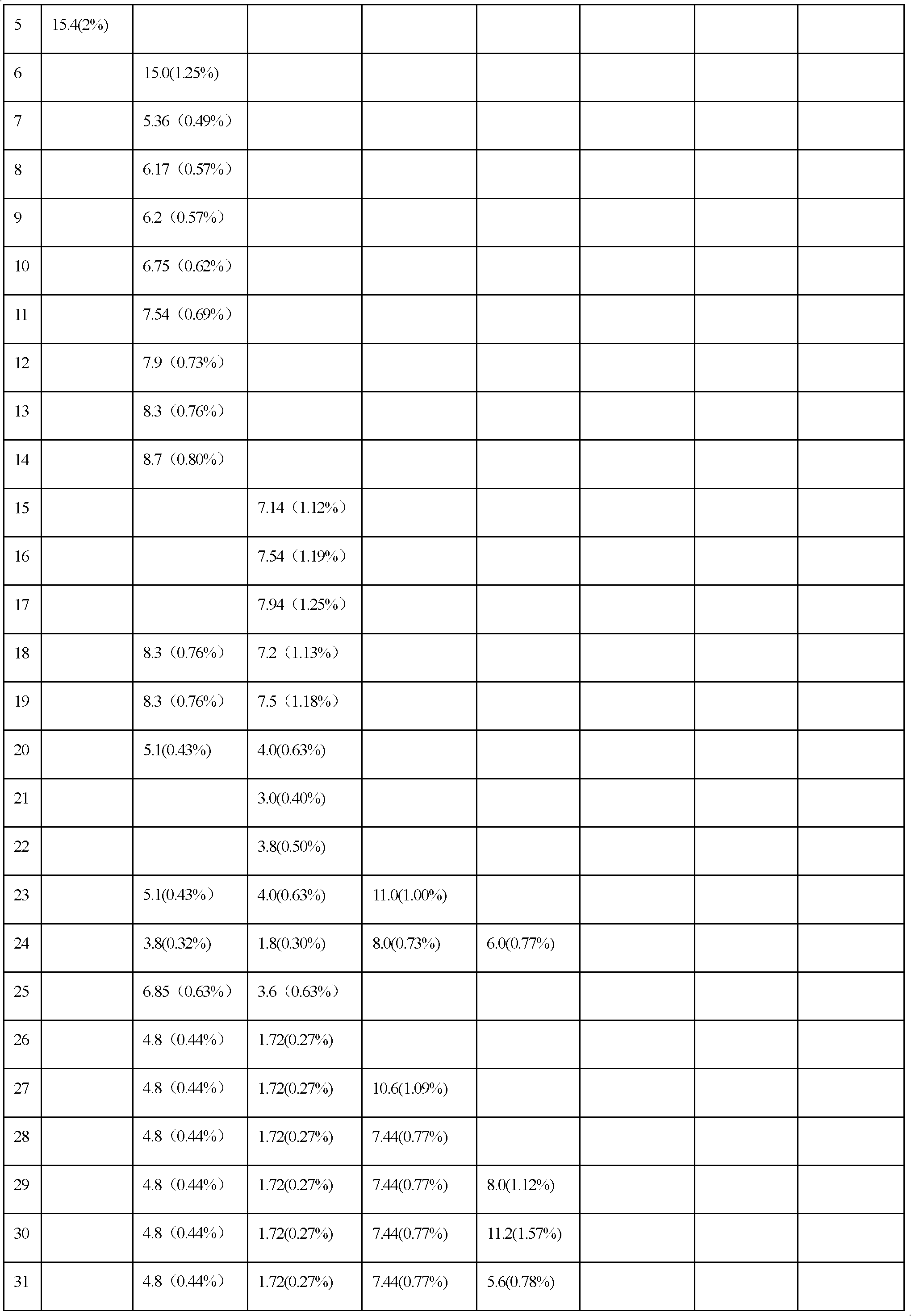

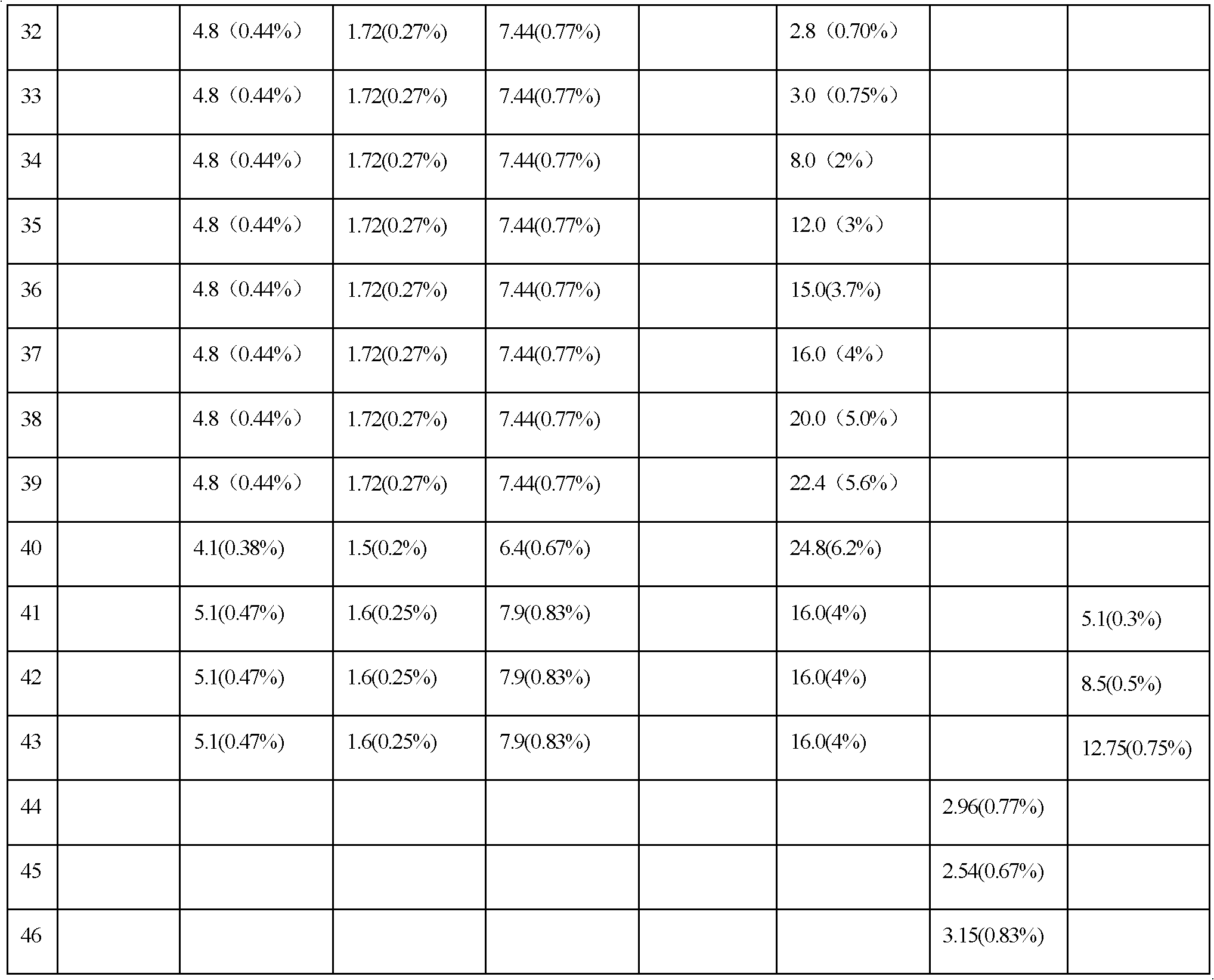

Embodiment 1~46

[0024] The specific preparation method is as follows:

[0025] (a) Preparation of acid phosphate: in a 500ml three-necked flask, add 7.2 milliliters of 85% phosphoric acid, under constant stirring, control the temperature at 110°C, slowly add 184.6g phosphorus pentoxide and 132g pentaerythritol alternately, Raise the temperature to 130°C and keep it warm for 4 hours to obtain a brown-red viscous liquid;

[0026] (b) Preparation of methylolated melamine: in a 250ml three-neck flask, first add 37% formaldehyde solution 60ml, 50ml water, adjust pH=7-9 with 10% NaOH solution, then add 100g melamine, and heat at 70-80°C 40 minutes between reactions;

[0027] (c) Coated ammonium polyphosphate: Disperse 200g of ammonium polyphosphate in 200ml of water at room temperature, and simultaneously add 96.6g of acid phosphate prepared in step (a) and all the methylols prepared in step (b) under stirring melamine, control the pH value between 3-6, heat up to 85°C, and react for 2 hours;

...

Embodiment 46

[0035] Example 46 Beneficial effect verification (taking polypropylene as an example):

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com