High-strength industrial polyester fiber and preparation method thereof

A polyester fiber and industrial technology, applied in the field of high-strength industrial polyester fiber and its preparation, can solve the problem that the degree of molecular chain orientation is limited, the inorganic nanoparticles are difficult to have good dispersibility and compatibility, and the spinning formation is affected. Processing performance and other issues, to achieve the effect of less additives and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

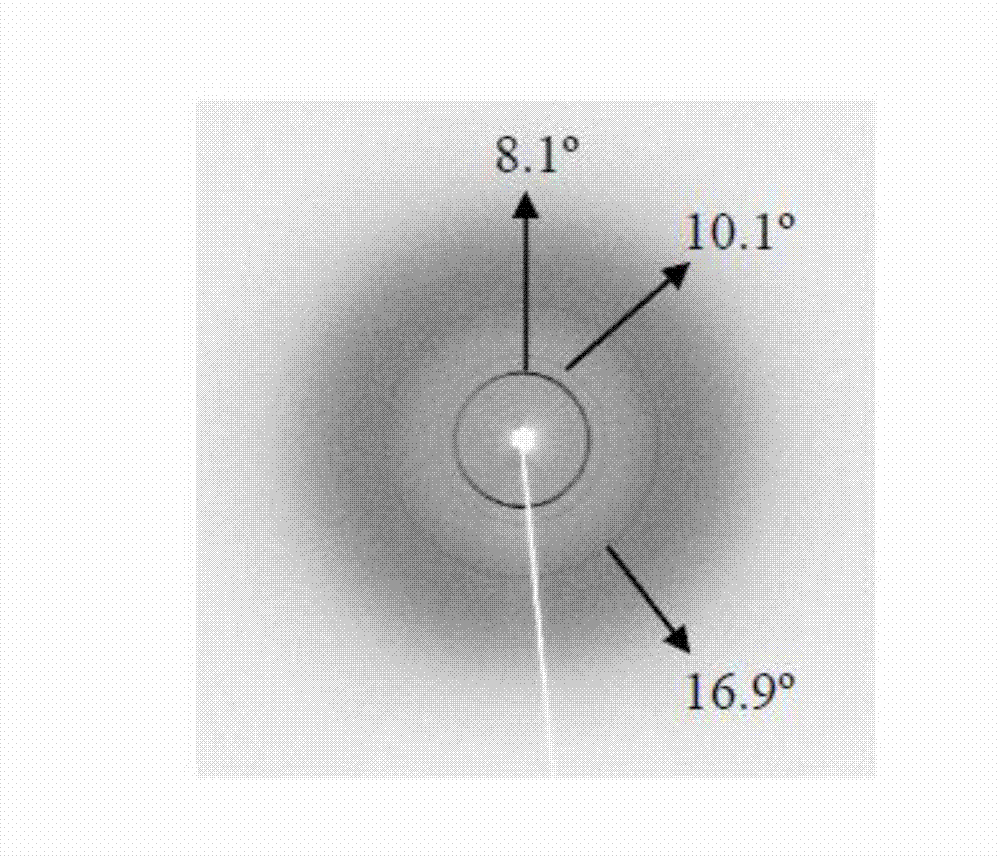

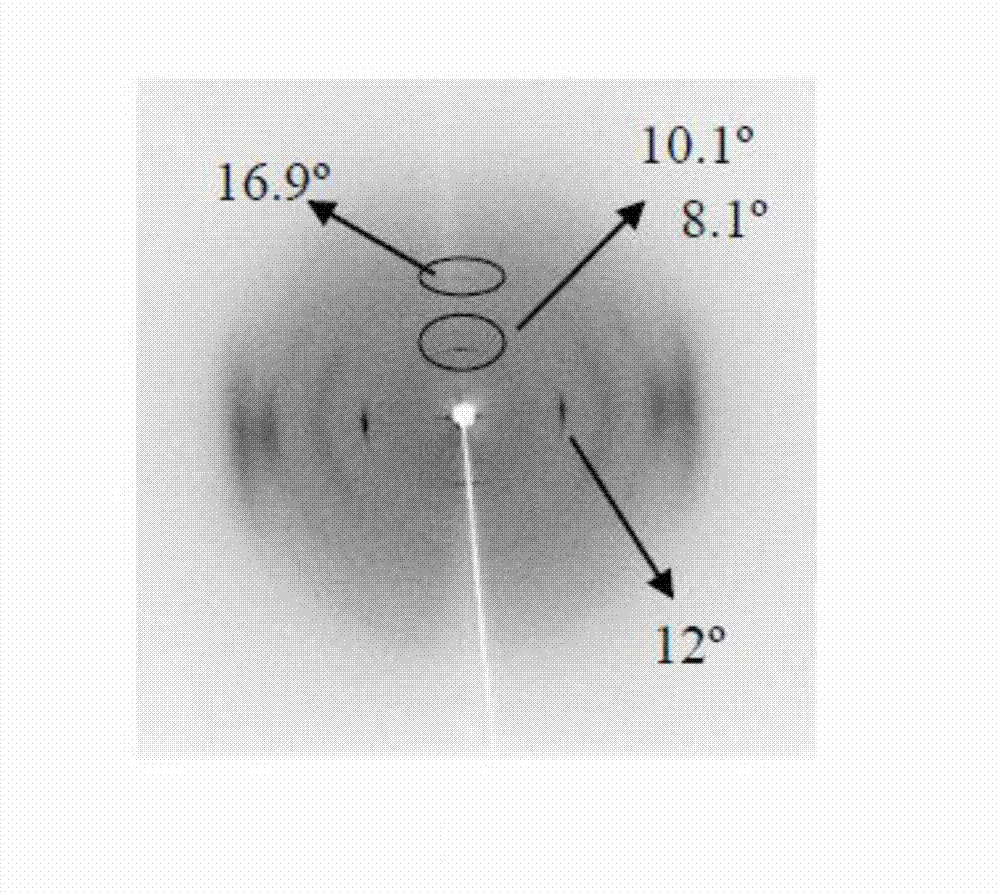

Image

Examples

Embodiment 1

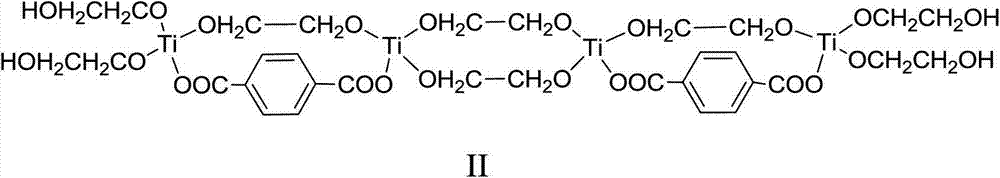

[0047] The preparation of embodiment 1 formula (I) compound

[0048] Add 23g of n-butyl titanate to 498g (1eq) of terephthalic acid and 279g (1.5eq) of ethylene glycol, under 0.1MPa gauge pressure, react at a temperature of about 150°C for 1.2h, then raise the temperature to about 260°C to continue the reaction . Collect the distilled liquid during the esterification reaction, and stop the reaction when the mole number of water in it is twice that of terephthalic acid (that is, the degree of esterification is about 100%). Cool the reaction system, collect the solid, and grind to obtain a powdery esterified compound containing the compound of formula (I). Further, dissolve the esterified compound with a 1:1 weight ratio phenol-tetrachloroethane solution, centrifuge, and collect The insoluble matter is the compound Ti of formula (I) 4 (OCH 2 CH 2 O) 8 (OOCC 6 h 4 COO) 2 h 4 .

Embodiment 2

[0049] Embodiment 2 melt blending method

[0050] PET slices with an intrinsic viscosity of 1.0dl / g and the compound of formula (I) prepared in Example 1 are mixed at a weight ratio of 80:20 and poured into the barrel of a twin-screw extruder, and sliced and pelletized after extrusion to obtain a composite parent grain.

[0051] Then the obtained composite masterbatch and PET chips with an intrinsic viscosity of 1.0dl / g are prepared according to the compound content of formula (I) at 0.3wt%, extruded through a screw extruder at a temperature of 295°C, and then cooled slowly Oiling and hot roller secondary drafting 6.0 times, and finally winding molding at a spinning speed of 3000m / min.

[0052] Performance test: GB / T14343-2003, FZ / T50002-1991, the breaking strength is 8.6cN / dtex, and the breaking elongation is 17%.

Embodiment 3

[0053] Embodiment 3 Melt Blending-Solid Phase Viscosification Method

[0054] PET chips with an intrinsic viscosity of 0.64dl / g and the compound prepared in Example 1 were mixed at a weight ratio of 99.5:0.5 and poured into the barrel of a twin-screw extruder. After extrusion, chips were pelletized to obtain a composite resin.

[0055] Under an absolute pressure of 100 Pa, the composite resin was subjected to a solid-state polycondensation reaction at a temperature of 240° C. for 22 hours to obtain high-molecular-weight composite modified PET chips with an intrinsic viscosity of 1.14 dl / g.

[0056] Then the high-molecular-weight composite modified PET chips are extruded through a screw extruder at a temperature of 293°C, then slowly cooled, cooled and oiled, and heated to a secondary draft of 6.3 times, and finally at a spinning speed of 3000m / min Roll forming.

[0057] Performance test: GB / T14343-2003, FZ / T50002-1991, the breaking strength is 8.9cN / dtex, and the breaking elo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com