Additive for wear resistance of lubricating oil

A technology of additives and lubricating oils, applied in the direction of additives, lubricating compositions, petroleum industry, etc., can solve problems such as difficult mass production and supply, accidents of cylinder scuffing and shafting, short service life of lubricating oil, etc., and achieve good results Effects of thermal oxidation stability, enhanced bearing capacity, and improved wear resistance

Active Publication Date: 2010-08-25

山东星火知识产权服务有限公司

View PDF0 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Currently applied and researched extreme pressure and antiwear additives such as sulfur phosphorus (SP) extreme pressure and antiwear additives for gear oils, zinc dialkyldithiophosphate (ZDDP) anti-oxidation, anti-corrosion and anti-wear for internal combustion engine oils and anti-wear hydraulic oils Multi-effect agent, organic molybdenum, tungsten friction reducer, organic copper and nano-copper sulfide friction reducer, nano-cerium, lanthanum rare earth anti-wear agent, nano-diamond, boron nitride, silicon dioxide and other ceramic anti-wear agents, colloidal graphite, Molybdenum disulfide, polytetrafluoroethylene anti-friction and anti-wear agents, zinc carbamate, copper, molybdenum, cadmium, antimony and other salts and their esters extreme pressure anti-wear agents, but these additives or used alone have low bearing capacity, such as sulfur , Phosphorus and Chlorine extreme pressure antiwear agents are prone to cylinder and shaft seizure under extreme overload conditions; or the extreme pressure antiwear agents used to form an effective protective oil film layer, such as sulfur phosphorus agent, are prone to excessive consumption and lead to lubricating oil The service life is short; or the processing conditions are strict, such as nano-ceramic, nano-diamond and imidazolium fluorine boron ionic liquid, etc., it is still difficult to produce and supply in large quantities

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

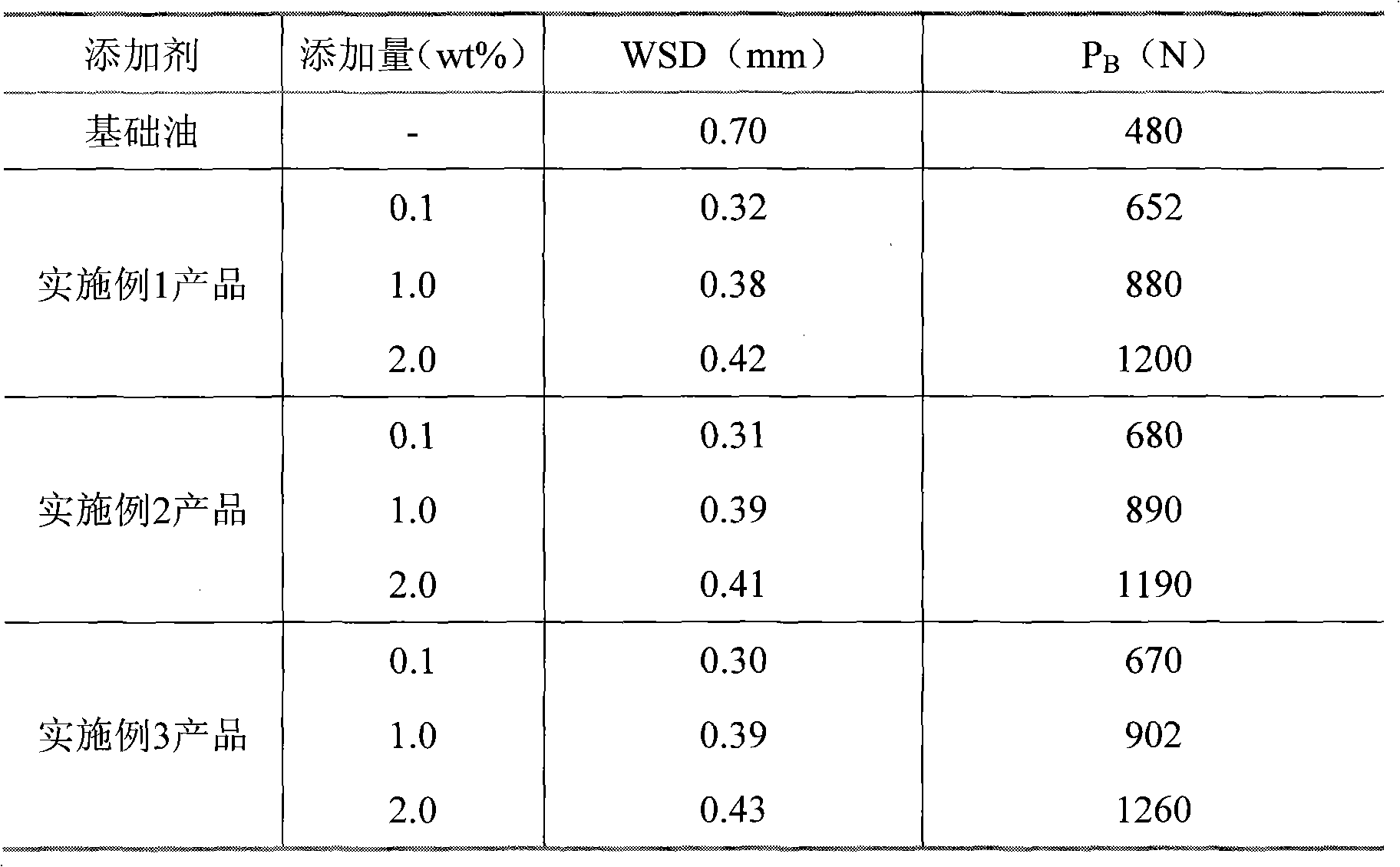

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an additive for wear resistance of lubricating oil, which comprises the following components in part by weight: 15 to 35 parts of antiwear agent, 6 to 29 parts of detergent dispersant and 12 to 26 parts of antioxidant preservative, wherein the antiwear agent consists of boric acid tributylester, phosphonic acid dibutyl ester, copper isooctoxyborate and cupric cyclohexoxylborate; the detergent dispersant consists of polybutene amine, polyisobutene carbamic acid ester and 2-aminopyridine; and the antioxidant preservative is boronized butanimide. The additive has wide use range, can be used in paraffin, naphthene and intermediate base oil, and also can be used in synthetic and semi-synthetic base oil. The additive has the advantages of effectively improving the wear resistance of the lubricating oil, strengthening the bearing capacity of the lubricating oil, making the lubricating oil have long service life, and having small dosage in the lubricating oil and simple and convenient preparation process.

Description

technical field The invention relates to an anti-wear additive for lubricating oil, in particular to an anti-wear additive for lubricating oil composed of an anti-wear agent, a detergent and dispersant, and an anti-oxidant and anti-corrosion agent. Background technique The operation of equipment is inseparable from lubricating oil, and lubricating oil cannot be separated from lubricating oil additives. Lubricating oil additives are the essence of various modern high-grade lubricating oils. According to statistics, about 30% of energy consumption is on friction, and 80% of damaged parts are scrapped by wear and tear. Therefore, improving lubricating performance to reduce friction, wear and prevent sintering is of great significance to the national economy. The most commonly used additives in lubricating oils are extreme pressure anti-wear additives, which are used to improve the tribological properties of base oils under boundary lubrication conditions, reduce frictional res...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M161/00C10N30/06

Inventor 张成如

Owner 山东星火知识产权服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com