Antifriction agent containing modified nanometer hexagonal boron nitride, preparation method of antifriction agent, and lubricating oil

A technology of hexagonal boron nitride and friction reducing agent, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of hindering the development of nano-lubricating additives, small size, etc., to increase the difficulty of dispersion and improve extreme pressure resistance. Wear and friction reduction, the effect of increasing the friction reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

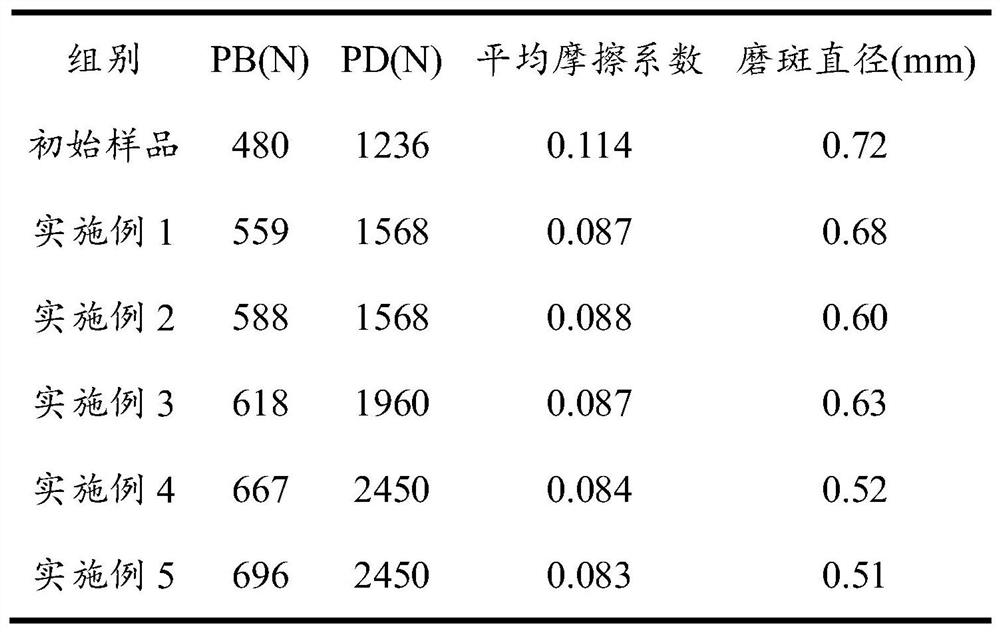

Examples

Embodiment 1

[0026] This embodiment provides a kind of friction reducing agent containing modified nano-hexagonal boron nitride, and its preparation method comprises the following steps:

[0027] S1. Add nano-hexagonal boron nitride with a particle size of 80nm and a purity of ≥99.9% to a mixed solution of 10mmol / L Tris buffer (pH=8.5) and absolute ethanol for 30 minutes of ultrasonic dispersion to obtain a dispersion.

[0028] S2. Add dopamine hydrochloride to the above dispersion liquid, carry out stirring reaction in an air atmosphere at 60°C for 6 hours with a constant temperature magnetic stirrer, set the rotation speed to 1000r / min, and then use a rotation speed of 10000r / min to perform centrifugation for solid-liquid separation, and then Washing with alcohol and deionized water in sequence, and finally vacuum-drying at 60° C. to obtain polydopamine-modified nano hexagonal boron nitride.

[0029] S3. Put the above-mentioned polydopamine-modified nano-hexagonal boron nitride in absolu...

Embodiment 2

[0033] This embodiment provides a kind of friction reducing agent containing modified nano-hexagonal boron nitride, and its preparation method comprises the following steps:

[0034] S1. Add nano-hexagonal boron nitride with a particle size of 80nm and a purity of ≥99.9% to a mixed solution of 10mmol / L Tris buffer (pH=8.5) and absolute ethanol for 30 minutes of ultrasonic dispersion to obtain a dispersion.

[0035] S2. Add dopamine hydrochloride to the above dispersion liquid, carry out stirring reaction in an air atmosphere at 60°C for 6 hours with a constant temperature magnetic stirrer, set the rotation speed to 1000r / min, and then use a rotation speed of 10000r / min to perform centrifugation for solid-liquid separation, and then Washing with alcohol and deionized water in sequence, and finally vacuum-drying at 60° C. to obtain polydopamine-modified nano hexagonal boron nitride.

[0036] S3. Put the above-mentioned polydopamine-modified nano-hexagonal boron nitride in absolu...

Embodiment 3

[0040] This embodiment provides a kind of friction reducing agent containing modified nano-hexagonal boron nitride, and its preparation method comprises the following steps:

[0041] S1. Add nano-hexagonal boron nitride with a particle size of 80nm and a purity of ≥99.9% to a mixed solution of 10mmol / L Tris buffer (pH=8.5) and absolute ethanol for 30 minutes of ultrasonic dispersion to obtain a dispersion.

[0042] S2. Add dopamine hydrochloride to the above-mentioned dispersion liquid, carry out the stirring reaction in an air atmosphere at 60°C with a constant temperature magnetic stirrer for 7 hours, set the rotation speed to 1000r / min, and then use a rotation speed of 10000r / min to perform centrifugation for solid-liquid separation, and then Washing with alcohol and deionized water in sequence, and finally vacuum-drying at 60° C. to obtain polydopamine-modified nano hexagonal boron nitride.

[0043] S3. Put the above-mentioned polydopamine-modified nano-hexagonal boron nitri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com