Organic phosphoric acid compound, synthesis method of compound and application of compound as chalcopyrite collector

A technology of organic phosphoric acid and synthesis method, which is applied in the fields of organic chemistry, chemical instruments and methods, and compounds of elements of Group 5/15 of the periodic table, etc., can solve the problems of high cost of chemicals and weak selectivity, and achieve good flotation effect. , Improve the grade and recovery rate, the effect of low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

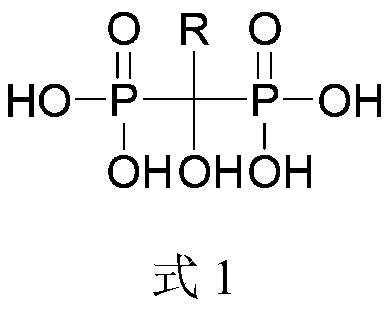

Method used

Image

Examples

Embodiment 1

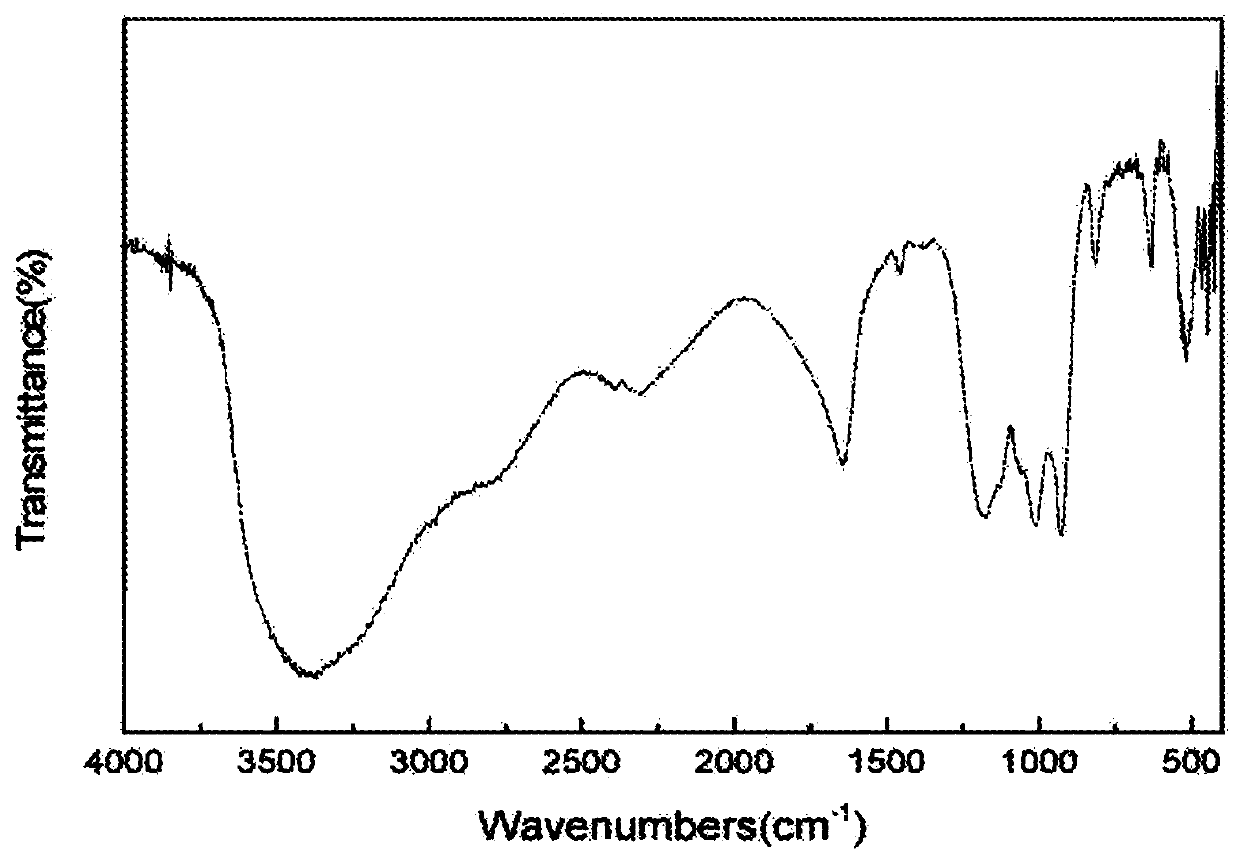

[0043]Mix 1 mol of acetic acid and 1 mol of phosphorous acid into a four-necked flask equipped with a stirrer, dropping funnel and thermometer, and keep stirring. Slowly add 0.5 mol of phosphorus pentoxide during the stirring process, and raise the temperature to 120-160°C after adding the reagents. React for 1 to 3 hours; after the reaction, pass water vapor for hydrolysis, control the temperature at 120 to 140°C during hydrolysis, and react for 4 to 6 hours, while steaming out excess acetic acid; then dilute the obtained intermediate product to 65% and add 5.0g of peroxide Hydrogen, stirred and reacted at 100-120°C for 5 hours, after the reaction was completed, it was adsorbed and filtered with activated carbon, and finally sodium hydroxide and methanol were added to the filtrate to crystallize the sodium salt, and the product obtained was the organic phosphoric acid compound collector. The infrared spectrum of the collector is as figure 1 shown.

[0044] The organophosphor...

Embodiment 2

[0049] Mix 1 mol of acetic acid and 1 mol of phosphorous acid into a four-necked flask equipped with a stirrer, dropping funnel and thermometer, and keep stirring. Slowly add 0.5 mol of phosphorus pentoxide during the stirring process, and raise the temperature to 120-160°C after adding the reagents. React for 1 to 3 hours; after the reaction, pass water vapor for hydrolysis, control the temperature at 120 to 140°C during hydrolysis, and react for 4 to 6 hours, while steaming out excess acetic acid; then dilute the obtained intermediate product to 65% and add 5.0g of peroxide Hydrogen, stirred and reacted at 100-120°C for 5 hours, after the reaction was completed, it was adsorbed and filtered with activated carbon, and finally sodium hydroxide and methanol were added to the filtrate to crystallize the sodium salt, and the product obtained was the organic phosphoric acid compound collector. The infrared spectrum of the collector is as figure 1 shown.

[0050] The obtained orga...

Embodiment 3

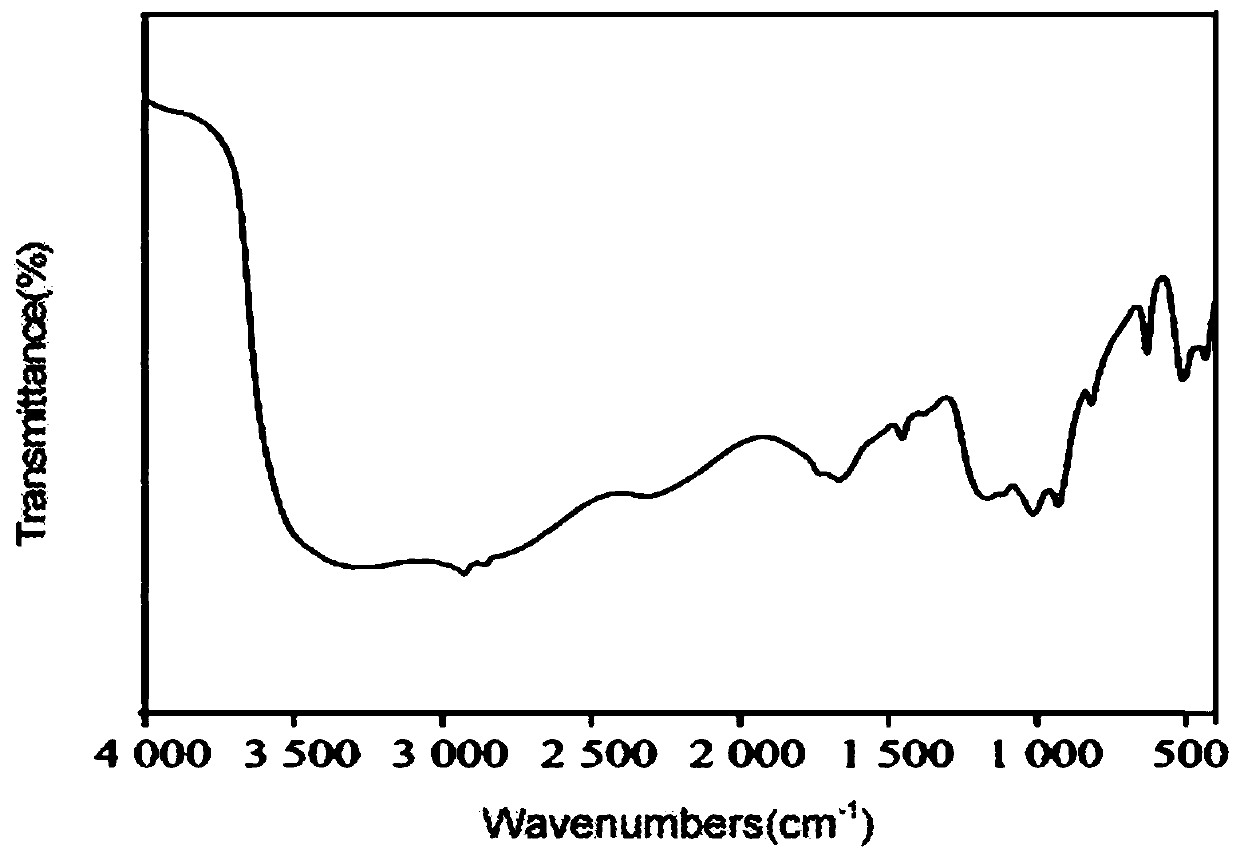

[0054] Mix 1.5 mol of butyric acid and 1 mol of phosphorous acid into a four-necked flask equipped with a stirrer, dropping funnel and thermometer, and keep stirring. Slowly add 0.5 mol of phosphorus pentoxide during the stirring process, and raise the temperature to 120-160 ℃, react for 1~3h; after the reaction, pass water vapor for hydrolysis, control the temperature at 120~140℃ during hydrolysis, react for 4~6h, and remove excess butyric acid at the same time; then dilute the obtained intermediate product to 65% and add 6.5g Hydrogen peroxide, stirred and reacted at 100-120°C for 5 hours, after the reaction was completed, it was adsorbed and filtered with activated carbon, and finally sodium hydroxide and methanol were added to the filtrate to crystallize the sodium salt, and the product obtained was the organic phosphoric acid compound collector. The infrared spectrum of the collector is as figure 2 shown.

[0055] The obtained organophosphoric acid compounds were applie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com