Water-based antirust liquid for metal

A metal anti-rust, water-based technology, applied in the field of metal protection, can solve the problems that the anti-rust effect cannot be further improved, poor adhesion, short lasting effect, etc., to avoid the decline of anti-rust performance, avoid product loss, improve long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

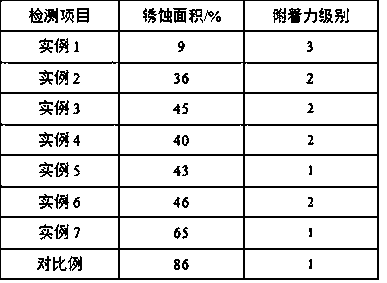

Examples

example 1

[0029] Mix polyvinyl alcohol and water at a mass ratio of 1:10 and pour it into the No. 1 beaker, stir and mix with a glass rod for 15 minutes, let it stand for swelling at room temperature for 5 hours, and then move the No. 1 beaker into a digital speed measuring constant temperature magnetic stirrer , at a temperature of 95°C and a rotation speed of 500r / min, stir and dissolve at a constant temperature for 60 minutes to obtain a polyvinyl alcohol solution; mix chitosan with a deacetylation degree of 90% and water at a mass ratio of 1:15 and pour into In the No. 2 beaker, stir and mix with a glass rod for 10 minutes, let it stand for swelling at room temperature for 8 hours, then move the No. 2 beaker into a digital speed measuring constant temperature magnetic stirrer, and dissolve it at a temperature of 90°C for 2 hours. , naturally cooled to room temperature, then added chitosanase with 5% chitosan mass to the No. , discharging, to get chitosan enzymatic solution; in parts...

example 2

[0031]Mix polyvinyl alcohol and water at a mass ratio of 1:10 and pour it into the No. 1 beaker, stir and mix with a glass rod for 15 minutes, let it stand for swelling at room temperature for 5 hours, and then move the No. 1 beaker into a digital speed measuring constant temperature magnetic stirrer , at a temperature of 95°C and a rotation speed of 500r / min, stir and dissolve at a constant temperature for 60 minutes to obtain a polyvinyl alcohol solution; mix chitosan with a deacetylation degree of 90% and water at a mass ratio of 1:15 and pour into In the No. 2 beaker, stir and mix with a glass rod for 10 minutes, let it stand for swelling at room temperature for 8 hours, then move the No. 2 beaker into a digital speed measuring constant temperature magnetic stirrer, and dissolve it at a temperature of 90°C for 2 hours. , naturally cooled to room temperature, then added chitosanase with 5% chitosan mass to the No. , discharging, to get chitosan enzymatic solution; in parts ...

example 3

[0033] Mix polyvinyl alcohol and water at a mass ratio of 1:10 and pour it into the No. 1 beaker, stir and mix with a glass rod for 15 minutes, let it stand for swelling at room temperature for 5 hours, and then move the No. 1 beaker into a digital speed measuring constant temperature magnetic stirrer , at a temperature of 95°C and a rotational speed of 500r / min, stir and dissolve at a constant temperature for 60 minutes to obtain a polyvinyl alcohol solution; in parts by weight, take 100 parts of polyvinyl alcohol solution, 10 parts of terephthalaldehyde, 10 parts by weight 1 part of polyamide modified hydrogenated castor oil, 0.3 part of chromium salt, 10 parts of organic acid, 10 parts of organic amine, 5 parts of emulsifier. Stir and mix at constant temperature for 5 hours under the condition of constant temperature, then add organic acid, organic amine, emulsifier, polyamide modified hydrogenated castor oil and chromium salt to the reaction kettle in sequence, and continue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com