Gallium nitride-based light-emitting diode and manufacturing method thereof

A light-emitting diode, gallium nitride-based technology, applied in electrical components, nanotechnology, circuits, etc., can solve the problems of low luminous efficiency of light-emitting diodes, and achieve the effect of improving luminous efficiency and injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

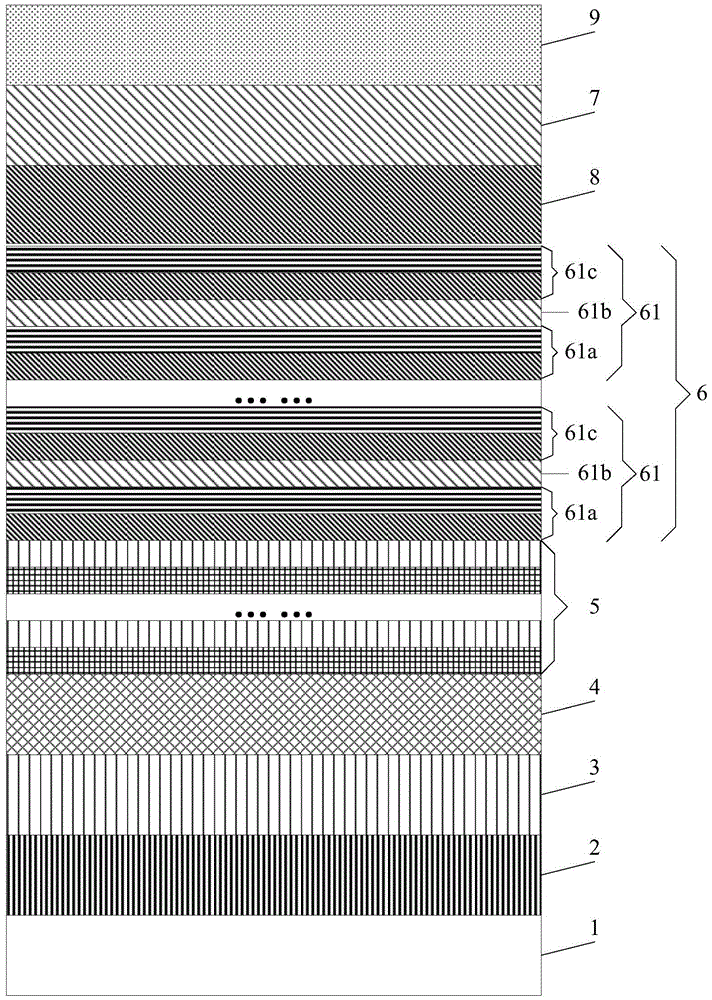

[0029] An embodiment of the present invention provides a gallium nitride-based light emitting diode, see figure 1 , the gallium nitride-based light-emitting diode includes a sapphire substrate 1, and a buffer layer 2, an undoped GaN layer 3, an N-type layer 4, an active layer 5, and a P-type layer 6 sequentially stacked on the sapphire substrate 1, The P-type layer 6 includes a plurality of P-type sublayers 61, and each P-type sublayer 61 includes a hole low barrier layer 61a, a hole supply layer 61b, a hole high barrier layer 61c, and a hole low barrier layer 61a. The hole high barrier layer 61c includes an AlGaN layer and an InGaN layer, and the hole providing layer 61b includes a P-type GaN layer.

[0030] In this embodiment, the sapphire substrate 1 adopts (0001) crystal orientation sapphire. Both the buffer layer 2 and the N-type layer 4 are GaN layers, and the active layer 5 includes alternately stacked InGaN layers and GaN layers.

[0031] Optionally, the buffer layer...

Embodiment 2

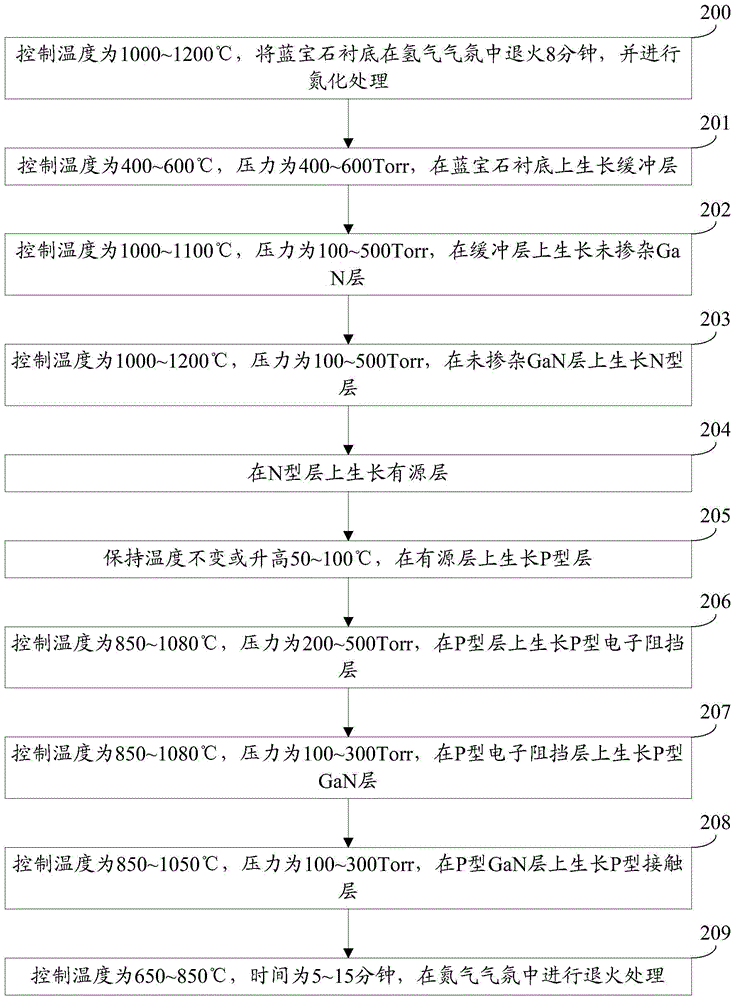

[0056] An embodiment of the present invention provides a method for manufacturing a gallium nitride-based light-emitting diode, see figure 2 , the production method includes:

[0057] Step 200: Control the temperature to 1000-1200° C., anneal the sapphire substrate in a hydrogen atmosphere for 8 minutes, and perform nitriding treatment.

[0058] Understandably, step 200 can clean the surface of the sapphire substrate.

[0059] In this embodiment, the sapphire substrate 1 adopts (0001) crystal orientation sapphire.

[0060] Step 201: Control the temperature to 400-600° C. and the pressure to 400-600 Torr to grow a buffer layer on the sapphire substrate.

[0061] In this embodiment, the buffer layer is a GaN layer.

[0062] Optionally, the thickness of the buffer layer may be 10-40 nm.

[0063] Preferably, the thickness of the buffer layer may be 15-35 nm.

[0064] Optionally, after step 201, the manufacturing method may also include:

[0065] The control temperature is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com