Fracturing technology for implementing ultrahigh flow conductivity

A conductivity and fracturing technology, applied in the field of oil and gas field development and research, can solve problems such as blocked channels, reduced fracture conductivity, and fracture pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

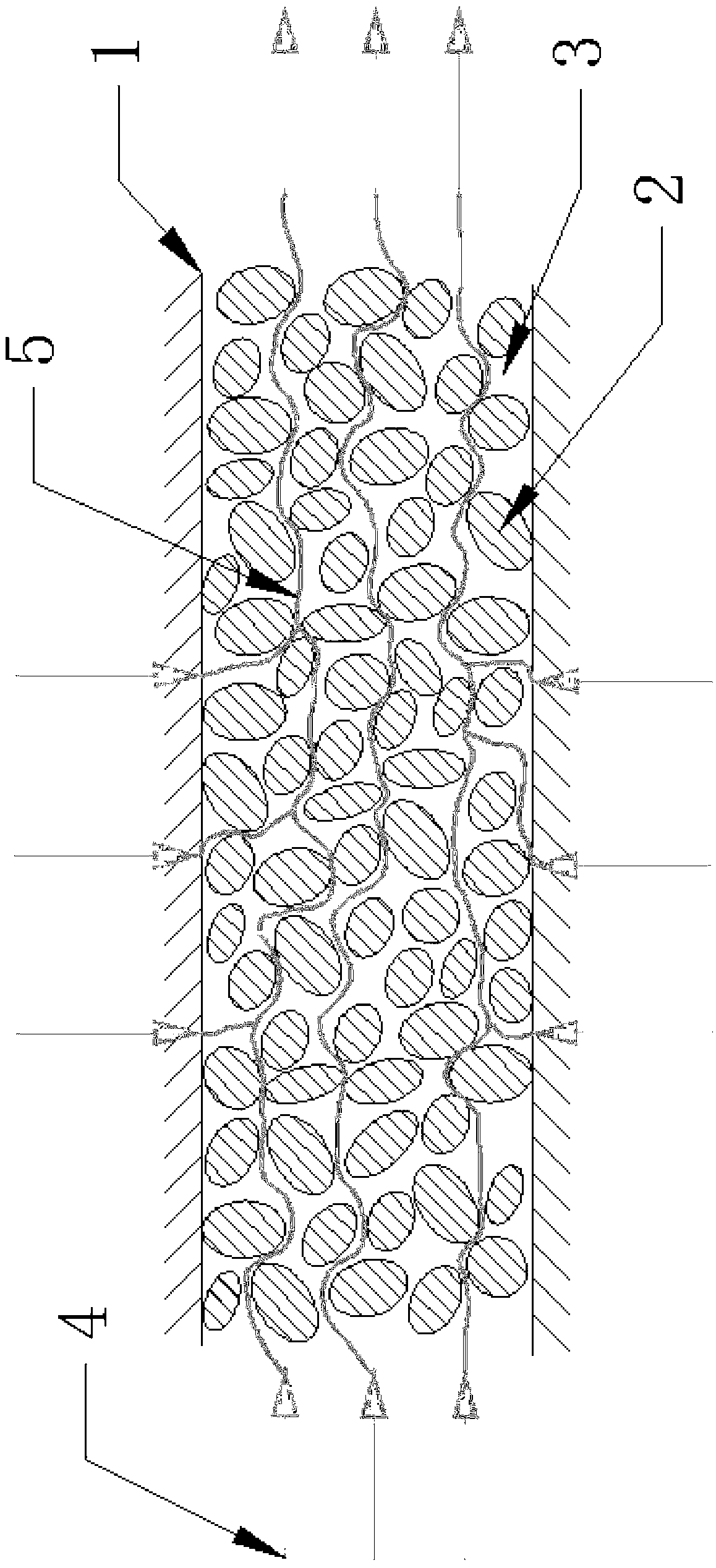

[0008] Technical scheme of the present invention is as follows:

[0009] A fracturing process to achieve ultra-high conductivity, the fracturing process of the present invention is suitable for target reservoirs with the following geological parameters: the ratio between Young's modulus and closure pressure is selected to be greater than or equal to 350; the present invention The principle and advantage of the design here are: the ratio between the Young's modulus and the closing pressure is a very important parameter for the fracturing process of the present invention, because the formation with a low Young's modulus is under high closing pressure It may cause the formation around the proppant cluster to collapse, thereby forming a narrow point and reducing the fracture conductivity; in order to maintain the ultra-high conductivity fracture in the formation, the ratio of Young's modulus to closure pressure is generally required to exceed 350; but when the ratio When it exceed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com