Direct Forced Draft Fluid Cooling Tower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

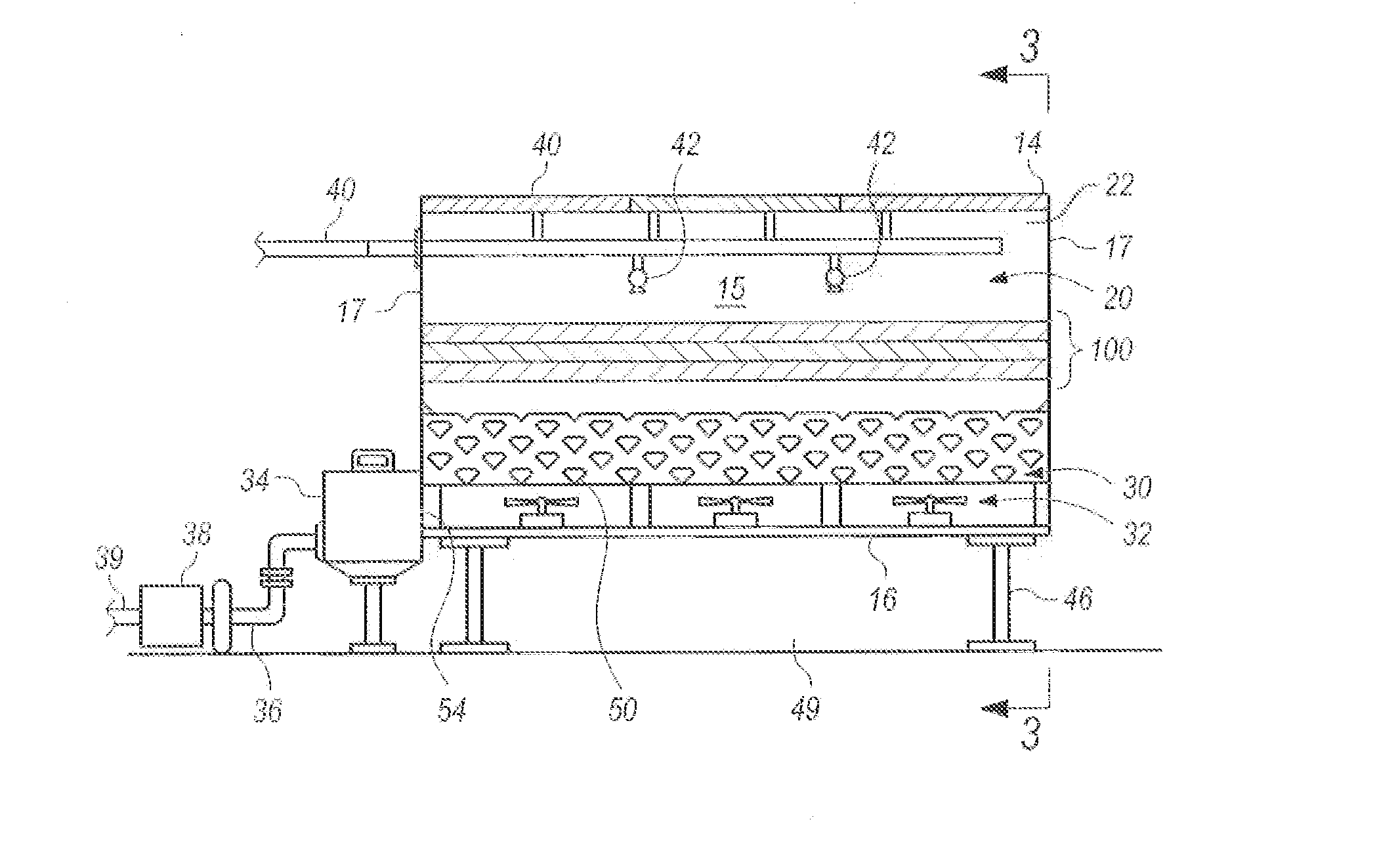

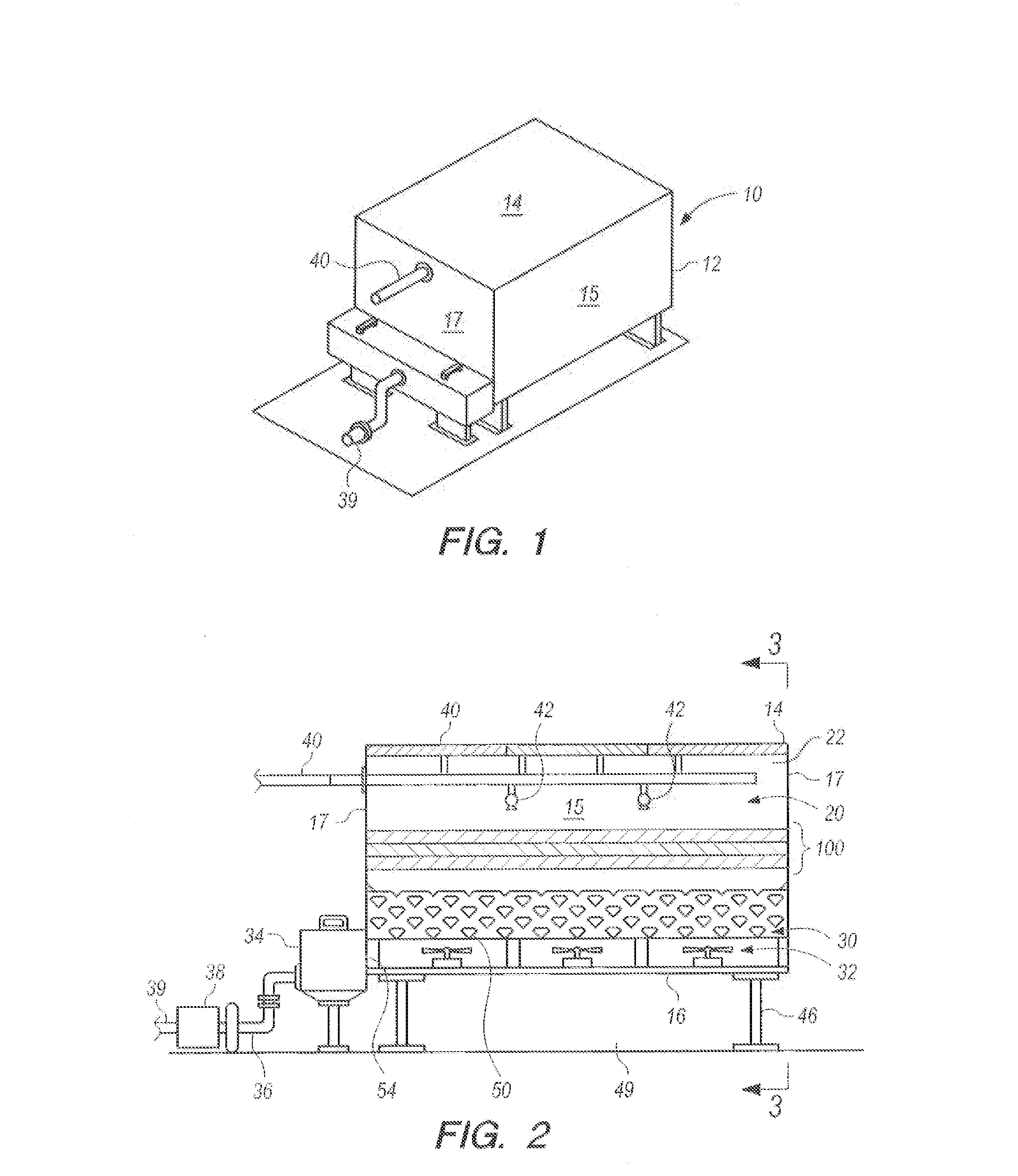

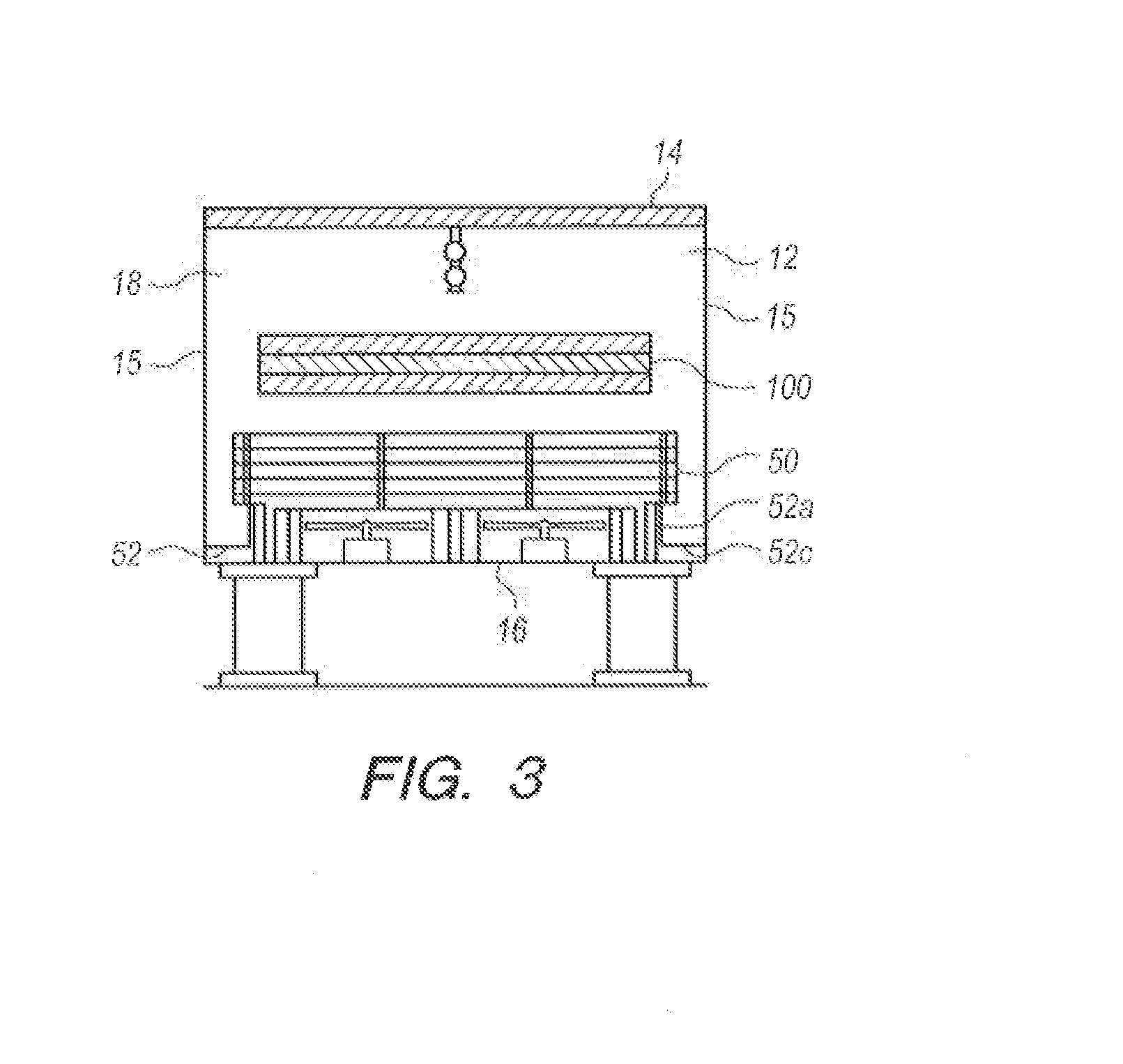

[0067]Referring now to the drawings in detail, and initially to FIG. 1, a direct draft cooling tower 10 as described in U.S. patent application Ser. No. 14 / 660,801 is illustrated. The cooling tower is designed to advantageously use the evaporation of water or other liquids to cool the liquids. The cooling tower includes an exterior housing 12 having an open top 14, vertical side walls 15, and end walls 17. As seen in FIG. 2, wherein a side wall 15 has been removed to illustrate the interior, housing 12 contains a liquid distribution system 20 at its upper end 22.

[0068]In an evaporative cooling tower as shown the liquid from distribution system 20 is passed countercurrent through an evaporative cooling media of well-known construction forming a layer 100 in the housing 12. The evaporative cooling media can take many forms, and typically could be cross-corrugated sheets of plastic material which form air passageways therebetween through which the liquid and air pass countercurrently. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Elevation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com