Continuous production system for preparing aqueous polyurethane dispersion, continuous production process of aqueous polyurethane dispersion and application of aqueous polyurethane dispersion

A water-based polyurethane and production process technology, applied in polyurea/polyurethane coatings, polyurea/polyurethane adhesives, transportation and packaging, etc., can solve the problem of high process energy consumption, product performance degradation, and no mention of continuous prepolymerization process Chemical production process and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

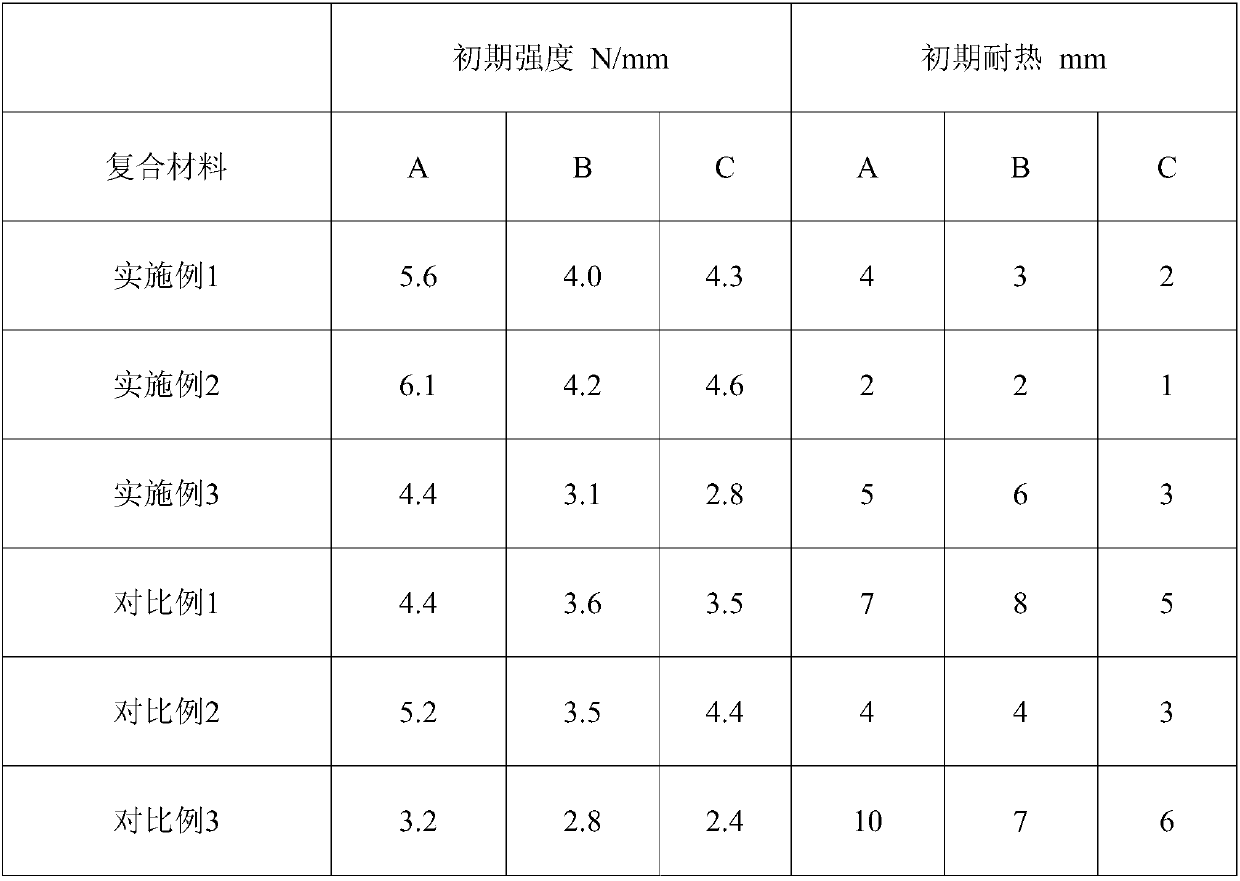

[0103] 1) The preparation process of the adhesive: mix 100g of water-based polyurethane dispersion and 0.05g of BYK024 (Byk Chemicals), stir at 500rpm for 5min, add 0.2g of Tego245 (Digo), stir for another 5min, and then add 0.15 gVesmody U604 (Wanhua Chemical), then stirred at 600rpm for 10min.

[0104] 2) Preparation of test samples

[0105] Coating with the prepared adhesive and obtaining a composite material on the substrate as a test sample:

[0106] composite material

Substrate 1

Substrate 2

A

rubber

rubber

B

canvas

canvas

C

pvc

pvc

[0107] Using a brush, first apply the adhesive dispersion thinly to a substrate strip 2.5 cm wide and 15 cm long and dry in an oven at 65° C. for 5 minutes, then remove and press at 30 kg / cm for 10 seconds, Composite material A was prepared.

[0108] Composite material B and composite material C were prepared using the same method.

[0109] 3) Test the peel strength of the ...

Embodiment 1

[0113] Embodiment 1 prepolymer method prepares waterborne polyurethane

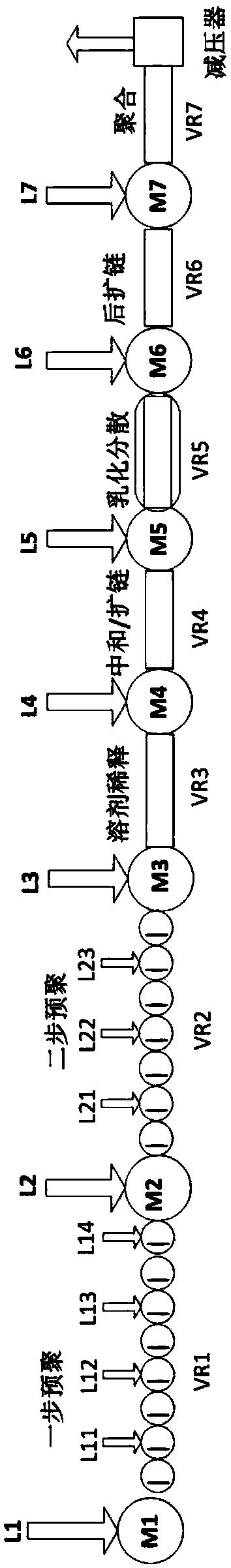

[0114] see figure 1 , pump 600 parts of TDI and 50 parts of acetone from the feeding port L1, mix completely in the first mixer M1 and preheat to 60°C, then enter the first tubular reactor VR1, and put 300 parts of PTMEG2000 (polytetrahydrofuran binary Alcohol, Mn=2000) is pumped in from feed port L11, 550 parts of PTMEG2000 are pumped in from feed port L12, 550 parts of PTMEG2000 are pumped in from feed port L13, 600 parts of PTMEG2000 are pumped in from feed port L14, four parts of PTMEG2000 are pumped in simultaneously, The pressure drop of VR1 is 0.04Mpa, the reaction temperature of VR1 is set to 85°C, and the residence time is 30 minutes; after the first step of reaction, the prepolymer I enters the second mixer M2, and at the same time, 120 parts of DMPA, 70 Parts of BDO, 310 parts of acetone, and 1 part of dibutyltin dilaurate catalyst are pumped into M2 from the feed port L2, mixed evenly, and th...

Embodiment 2

[0115] Embodiment 2 acetone method prepares waterborne polyurethane

[0116] Pump 150 parts of HDI (hexamethylene diisocyanate), 140 parts of IPDI (isophorone diisocyanate) and 240 parts of acetone from the feeding port L1, mix completely in the first mixer M1 and preheat to 60°C After entering the first tubular reactor VR1, 400 parts of PBA2000 (polybutylene adipate glycol, Mn=2000) are pumped in from the feeding port L11, 500 parts of PBA2000 are pumped in from the feeding port L12, and 500 parts of PBA2000 Pump in from feeding port L13, pump in 700 parts of PBA2000 from feeding port L14, pump in four parts of PBA2000 at the same time, the pressure drop of VR1 is 0.04Mpa, the reaction temperature of VR1 is set at 85°C, and the residence time is 30 minutes; the first step After the reaction, the obtained prepolymer I enters the second mixer M2. At the same time, 2 parts of dibutyltin dilaurate are pumped into M2 from the feeding port L2, and after mixing evenly, enter the sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com