Bubbling tower and method for producing benzoic acid by liquid phase oxidation of toluene with the same

A liquid phase oxidation, benzoic acid technology, applied in chemical methods, chemical instruments and methods for reacting liquids and gaseous media, and liquid and gas reactions under foam/aerosol/bubble, etc., can solve the problem of crystalline benzoic acid. The content is difficult to reach 99.99%, the yield of industrial grade benzoic acid and its content are reduced, and the benzoic acid is not easy to be purified, etc., to achieve the effects of high gas-liquid mass transfer capacity and material mixing capacity, efficient use of reaction heat, and easy cleaning of scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

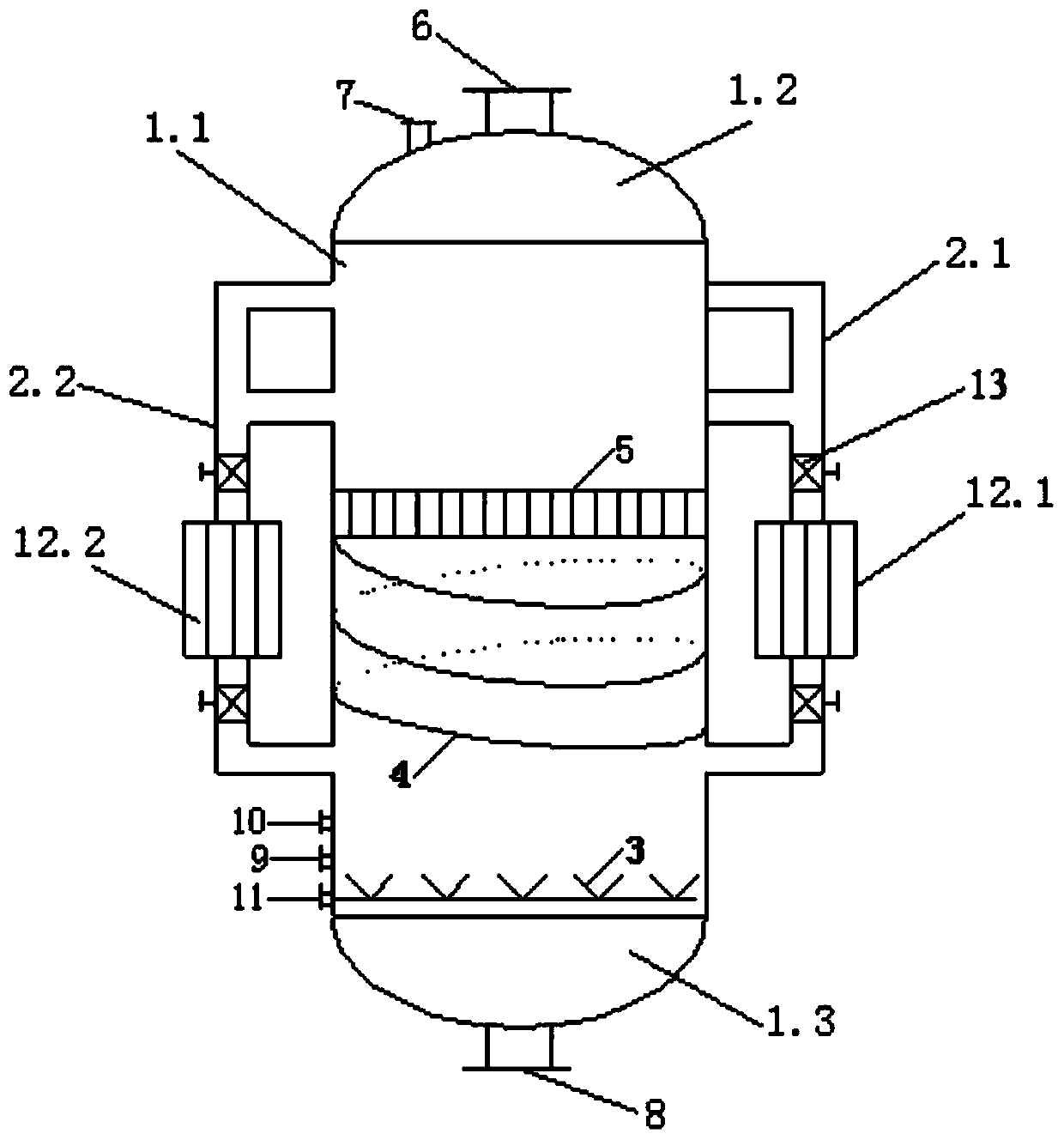

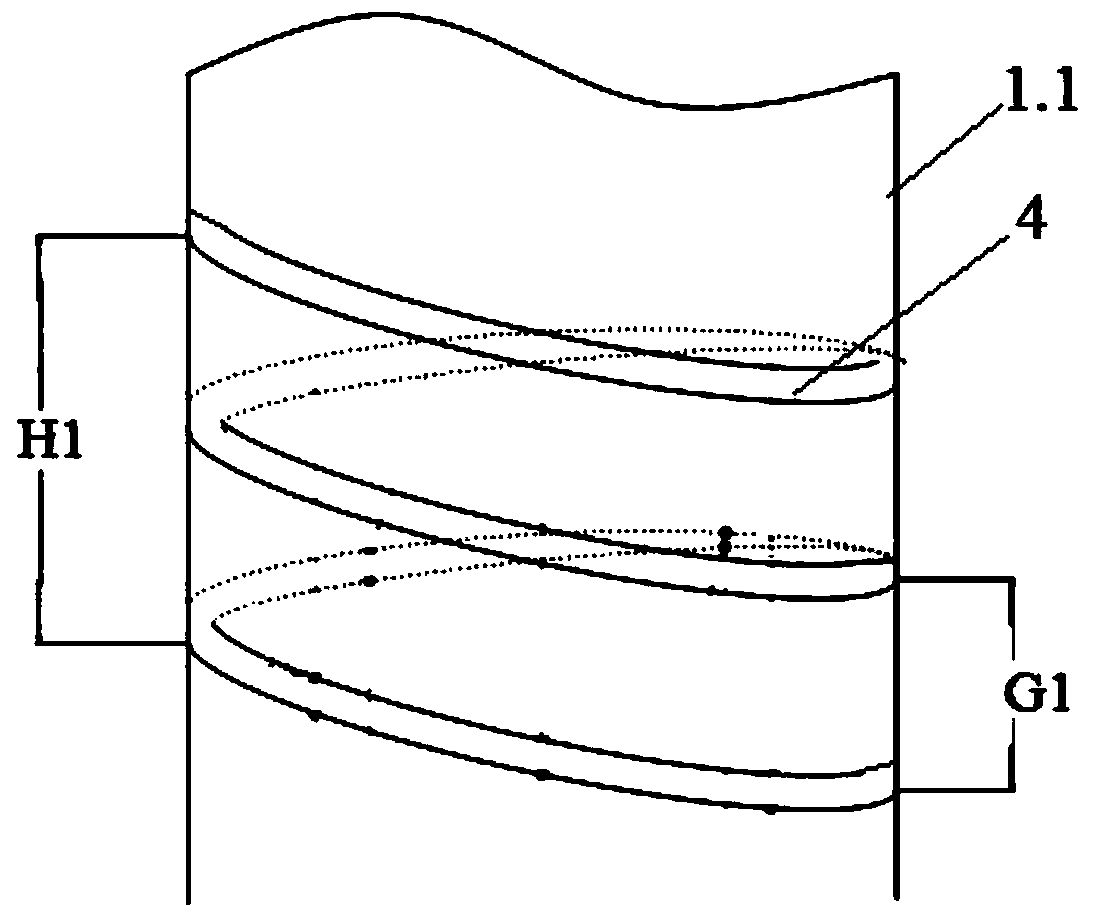

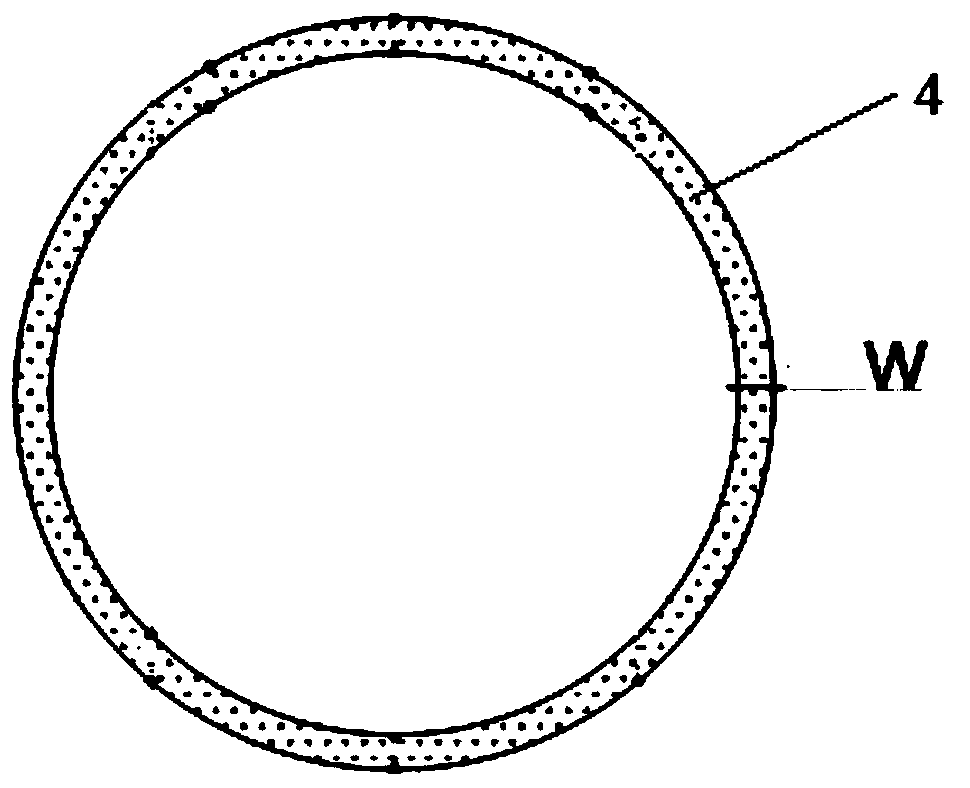

[0047] In order to facilitate the description of the size of the bubble tower device, the following symbols are used to represent the size of each component: diameter of the cylindrical tower body D; height of the cylindrical tower body H; height of the spiral plate member H1; width of the spiral plate W; distance between the spiral plates G1; Tube diameter D1; spoiler height H2; corrugated plate spacing G2.

[0048] In this embodiment, the heat exchanger of the bubble column device used for the liquid-phase oxidation of toluene to produce benzoic acid is a tube-and-tube heat exchanger, with a single heat exchange area of 5m 2 , the specific dimensions of other components are as follows (in m):

[0049] D H H1 W G1 D1 H2 G2 0.4 1 0.6 0.02 0.12 0.07 0.1 0.002

[0050] Use the bubble column device of the present invention to carry out toluene oxidation reaction under the following conditions, during stable production, toluene flow rate 1.6t / h, a...

Embodiment 2

[0054] In this example, the heat exchanger of the bubble column device used for the liquid-phase oxidation of toluene to produce benzoic acid is a plate heat exchanger, with a single heat exchange area of 7m 2 , the specific dimensions are as follows (in m):

[0055] D H H1 W G1 D1 H2 G2 0.4 1 0.45 0.04 0.05 0.07 0.05 0.003

[0056] Use the bubble column device of the present invention to carry out toluene oxidation reaction under the following conditions, during stable production, toluene flow rate 1.6t / h, air 700Nm 3 / h, catalyst concentration 160ppm, reaction temperature 165°C, reaction pressure 0.65MPa. The oxygen content in the tail gas is 0.08%, and the main components and contents of the oxidation liquid in the liquid phase outlet 8 are:

[0057] Oxidizing solution components Content / wt% benzene 0.63 toluene 55.8 benzoic acid 38.2 Benzyl Benzoate 1.7 biphenyl 0.007 other balance

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com