Bubble column device and its method for producing benzoic acid by liquid-phase oxidation of toluene

A technology of liquid-phase oxidation and benzoic acid, applied in the direction of chemical methods, chemical instruments and methods for reacting liquid and gaseous media, and the reaction of liquid and gas under foam/aerosol/bubble, etc., can solve the problem of crystalline benzoic acid The content is difficult to reach 99.99%, the yield of industrial-grade benzoic acid and its content are reduced, and the gas-liquid phase mass transfer is unfavorable, so as to achieve efficient use of reaction heat, increase the overall reaction rate, and facilitate cleaning of scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

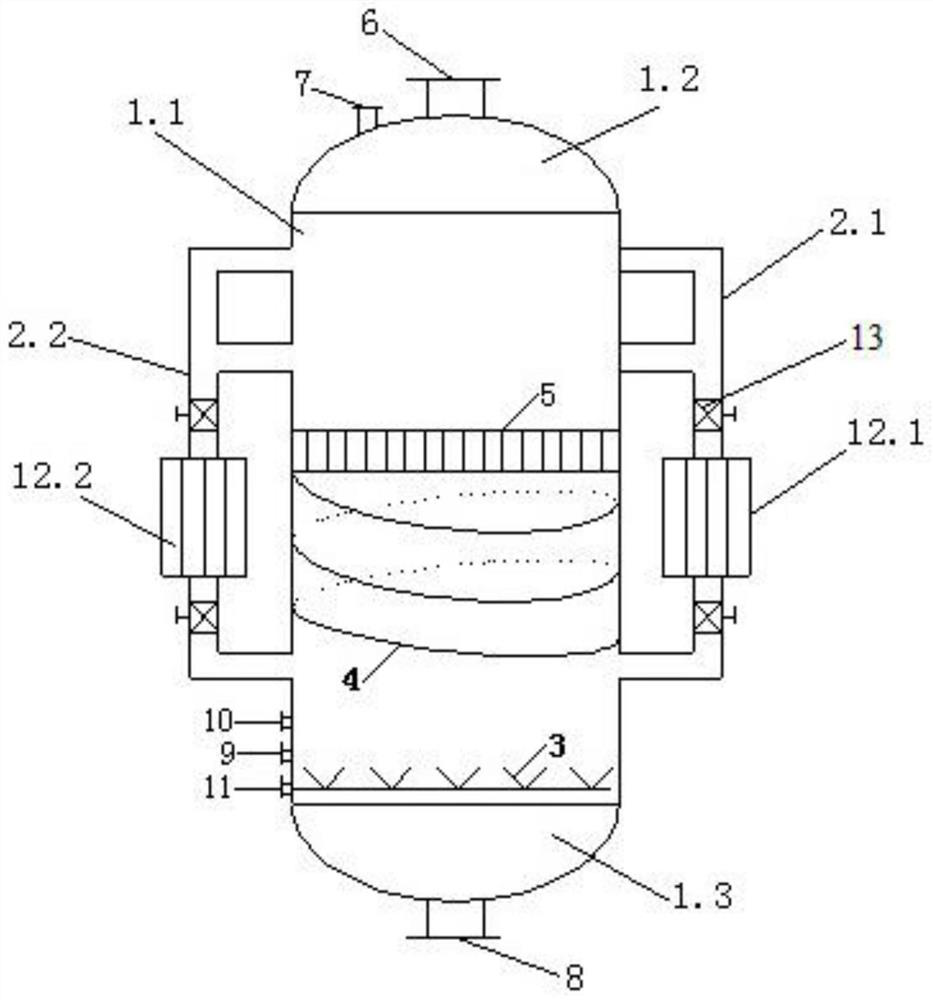

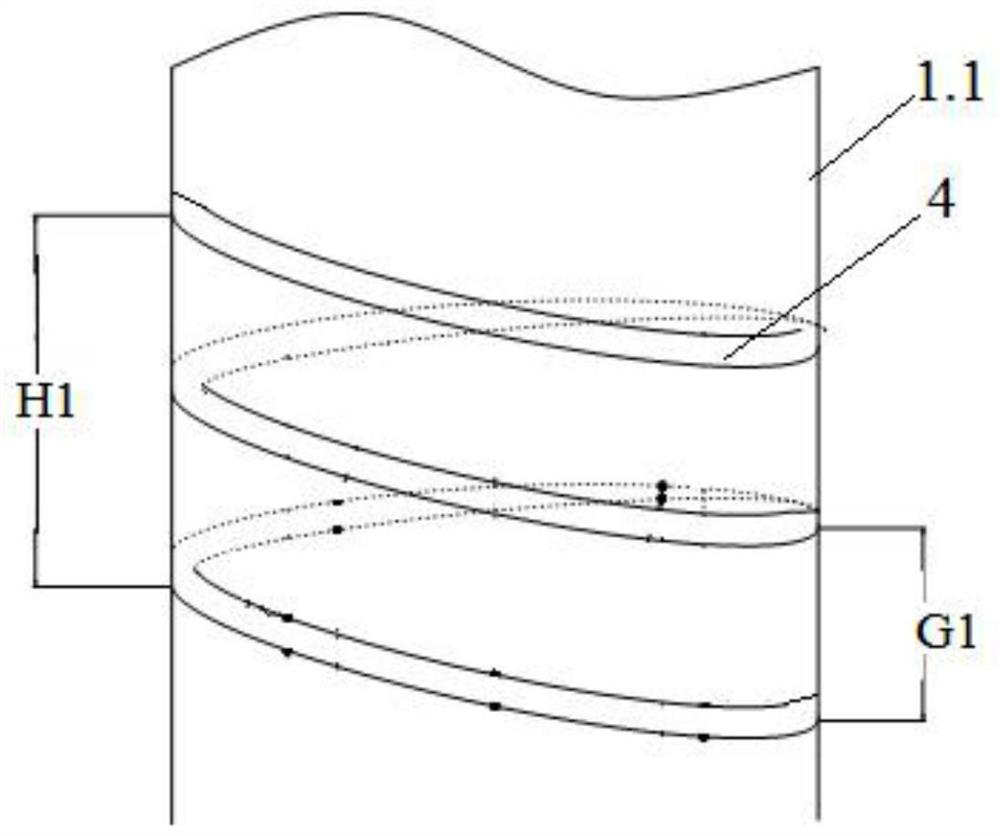

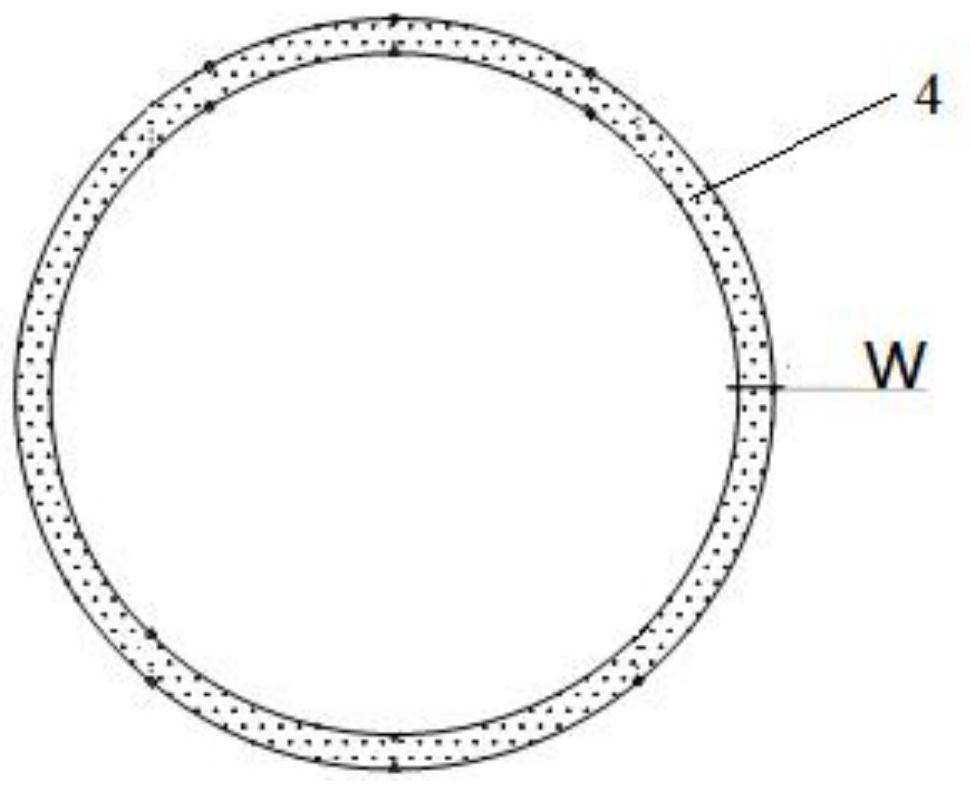

[0047] In order to facilitate the description of the size of the bubble tower device, the following symbols are used to represent the size of each component: diameter of the cylindrical tower body D; height of the cylindrical tower body H; height of the spiral plate member H1; width of the spiral plate W; distance between the spiral plates G1; Tube diameter D1; spoiler height H2; corrugated plate spacing G2.

[0048] In this embodiment, the heat exchanger of the bubble column device used for the liquid-phase oxidation of toluene to produce benzoic acid is a tube-and-tube heat exchanger, with a single heat exchange area of 5m 2 , the specific dimensions of other components are as follows (in m):

[0049] D H H1 W G1 D1 H2 G2 0.4 1 0.6 0.02 0.12 0.07 0.1 0.002

[0050] Use the bubble column device of the present invention to carry out toluene oxidation reaction under the following conditions, during stable production, toluene flow rate 1.6t / h, a...

Embodiment 2

[0054] In this example, the heat exchanger of the bubble column device used for the liquid-phase oxidation of toluene to produce benzoic acid is a plate heat exchanger, with a single heat exchange area of 7m 2 , the specific dimensions are as follows (in m):

[0055] D H H1 W G1 D1 H2 G2 0.4 1 0.45 0.04 0.05 0.07 0.05 0.003

[0056] Use the bubble column device of the present invention to carry out toluene oxidation reaction under the following conditions, during stable production, toluene flow rate 1.6t / h, air 700Nm 3 / h, catalyst concentration 160ppm, reaction temperature 165°C, reaction pressure 0.65MPa. The oxygen content in the tail gas is 0.08%, and the main components and contents of the oxidation liquid in the liquid phase outlet 8 are:

[0057] Oxidizing solution components Content / wt% benzene 0.63 toluene 55.8 benzoic acid 38.2 Benzyl Benzoate 1.7 biphenyl 0.007 other balance

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com