Nanofiber filter material

A filter material and nanofiber technology, which is applied in the fields of filtration and separation, chemical instruments and methods, separation methods, etc., can solve the problems of limiting the wide application of high-efficiency filter materials, reducing air permeability, and reducing service life, and achieving productivity The effect of high and low pressure drop, high quality factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

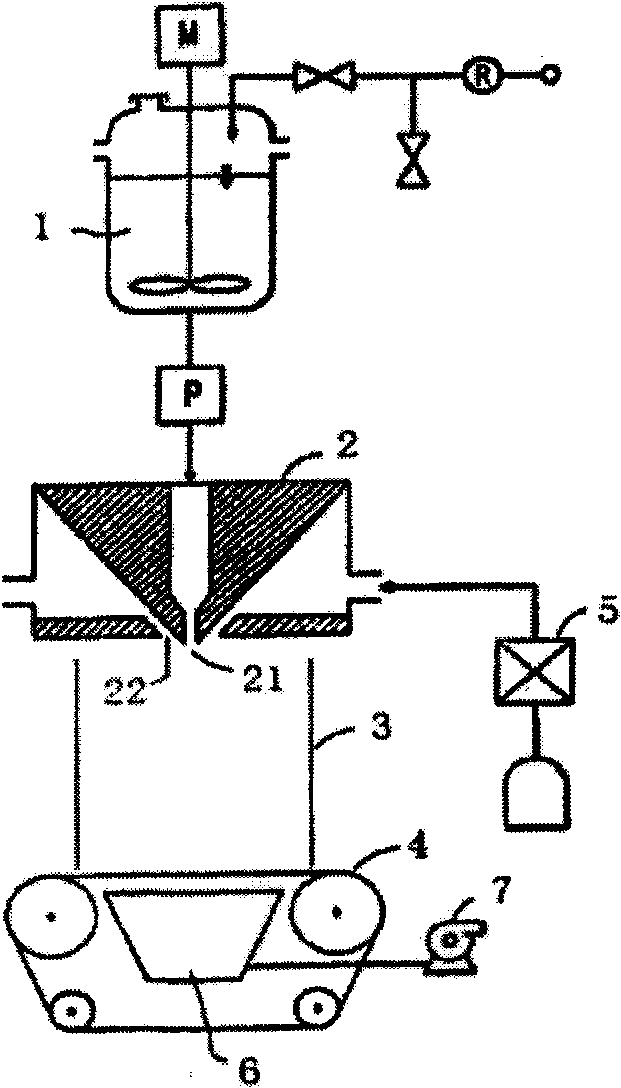

Method used

Image

Examples

Embodiment 1

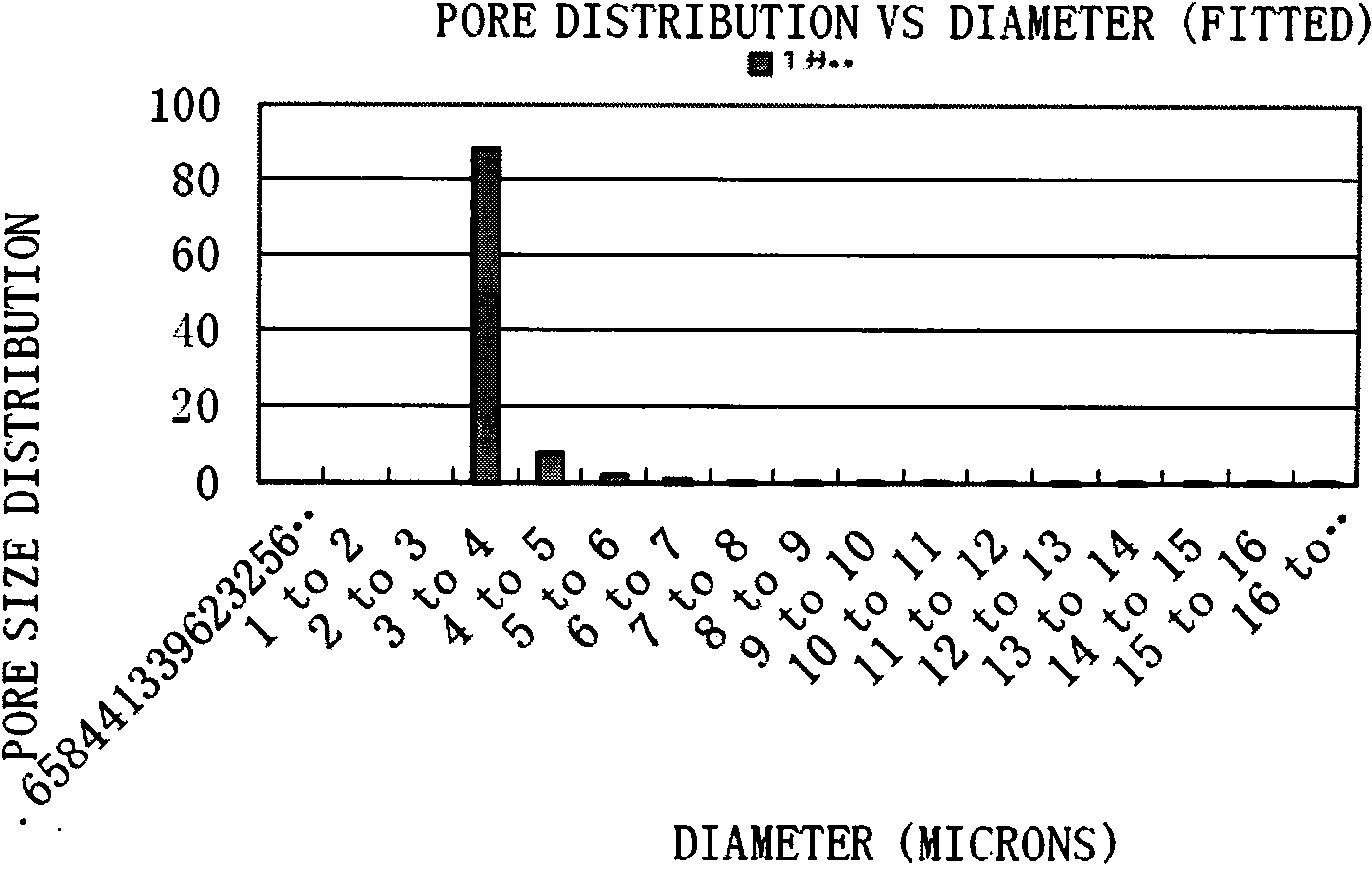

[0020] The nanofiber filter material is prepared by the solution jet spinning technology in Chinese invention patent ZL201110041792.3, specifically, the nanofiber layer is prepared by preparing an 18% anhydrous formic acid solution of nylon 6 polymer through the solution jet spinning technology. The diameter of the obtained nanofiber filter material is a continuous polymer porous nanofiber layer with a diameter of 500-700 nanometers, the proportion of pores with a pore diameter of 4um-6um in the nanofiber layer accounts for more than 95%, and the grammage of the nanofiber layer is 4.5g / m 2, the nanofiber is a three-dimensional curled shape, and the porosity of the nanofiber layer is more than 95%; when the average particle size is 0.3 μm particles are filtered by the airflow with a surface velocity of 5.33 cm / s, the filtration efficiency of the nanofiber layer of the filter material is 85% or more, the initial pressure drop is 3mmH 2 O, the filter quality factor Q of the filte...

Embodiment 2

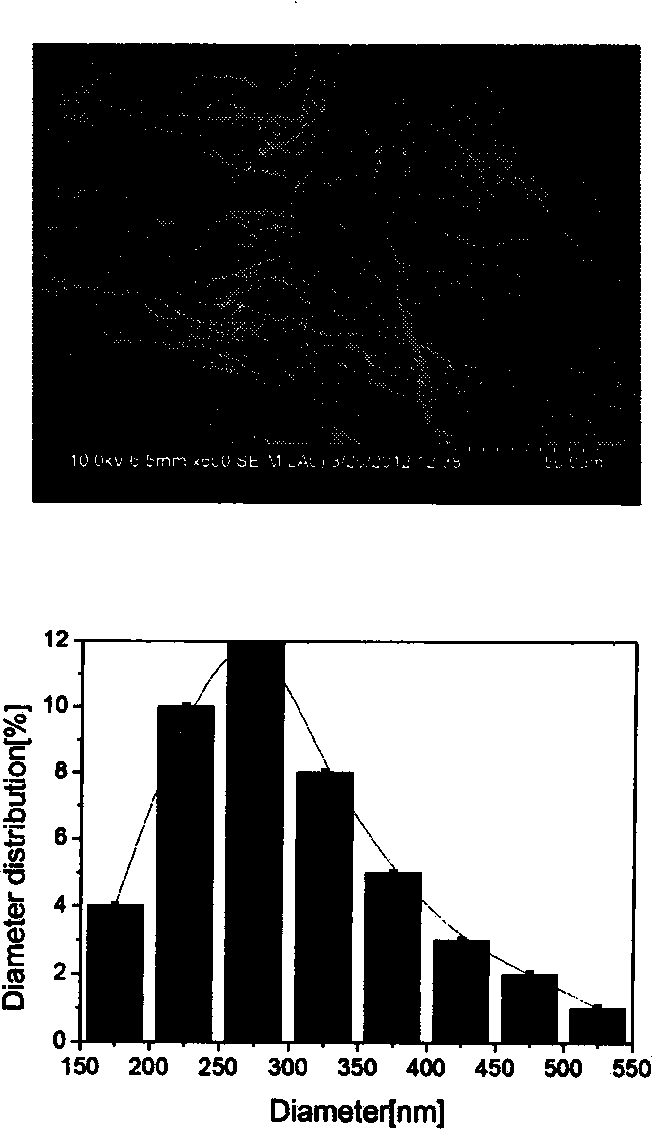

[0022] The nanofiber filter material is prepared by the solution jet spinning technology in Chinese invention patent ZL201110041792.3, specifically, 14% N,N-Di The nanofibrous layer was prepared from methylformamide (DMF) solution. The diameter of the obtained nanofiber filter material is a continuous polymer porous nanofiber layer with a diameter of 200-500 nanometers, the proportion of pores with a pore diameter of 2um-5um in the nanofiber layer accounts for more than 95%, and the gram weight of the nanolayer is 3.5g / m 2 , the nanofiber is a three-dimensional crimped shape, and the porosity of the nanofiber layer is 90%; when the average particle diameter is filtered by an airflow with a surface velocity of 5.33cm / s when the average particle size is 0.3 μm particles, the filtration efficiency of the nanofiber layer of the filter material is More than 90%, the initial pressure drop is 5mmH 2 O, the filter quality factor Q of the filter material F is 0.07 (1 / mmH 2 O).

Embodiment 3

[0024] The nanofiber filter material is prepared by the solution jet spinning technology in the Chinese invention patent ZL201110041792.3, specifically the 12% N,N- Dimethylacetamide (DMAc) solution to prepare nanofiber layer. The diameter of the obtained nanofiber filter material is a continuous polymer porous nanofiber layer with a diameter of 50-200 nanometers, the proportion of pores with a pore diameter of 1um-2um in the nanofiber layer accounts for more than 95%, and the grammage of the nanolayer is 2.5g / m 2 , the nanofiber is a three-dimensional curled shape, and the porosity of the nanofiber layer is more than 95%; when the average particle size is 0.3 μm particles are filtered by the airflow with a surface velocity of 5.33 cm / s, the filtration efficiency of the nanofiber layer of the filter material is Over 95%, the initial pressure drop is 8mmH 2 O, the filter quality factor Q of the filter material F is 0.06 (1 / mmH 2 O).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com