Particulate matter-containing exhaust emission controlling filter, exhaust emission controlling method and device

A technology for particulate matter and exhaust gas purification devices, used in exhaust devices, chemical instruments and methods, noise reduction devices, etc., can solve problems such as large ventilation loss, yellow smoke, secondary pollution, etc., to reduce pressure drop, high performance, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

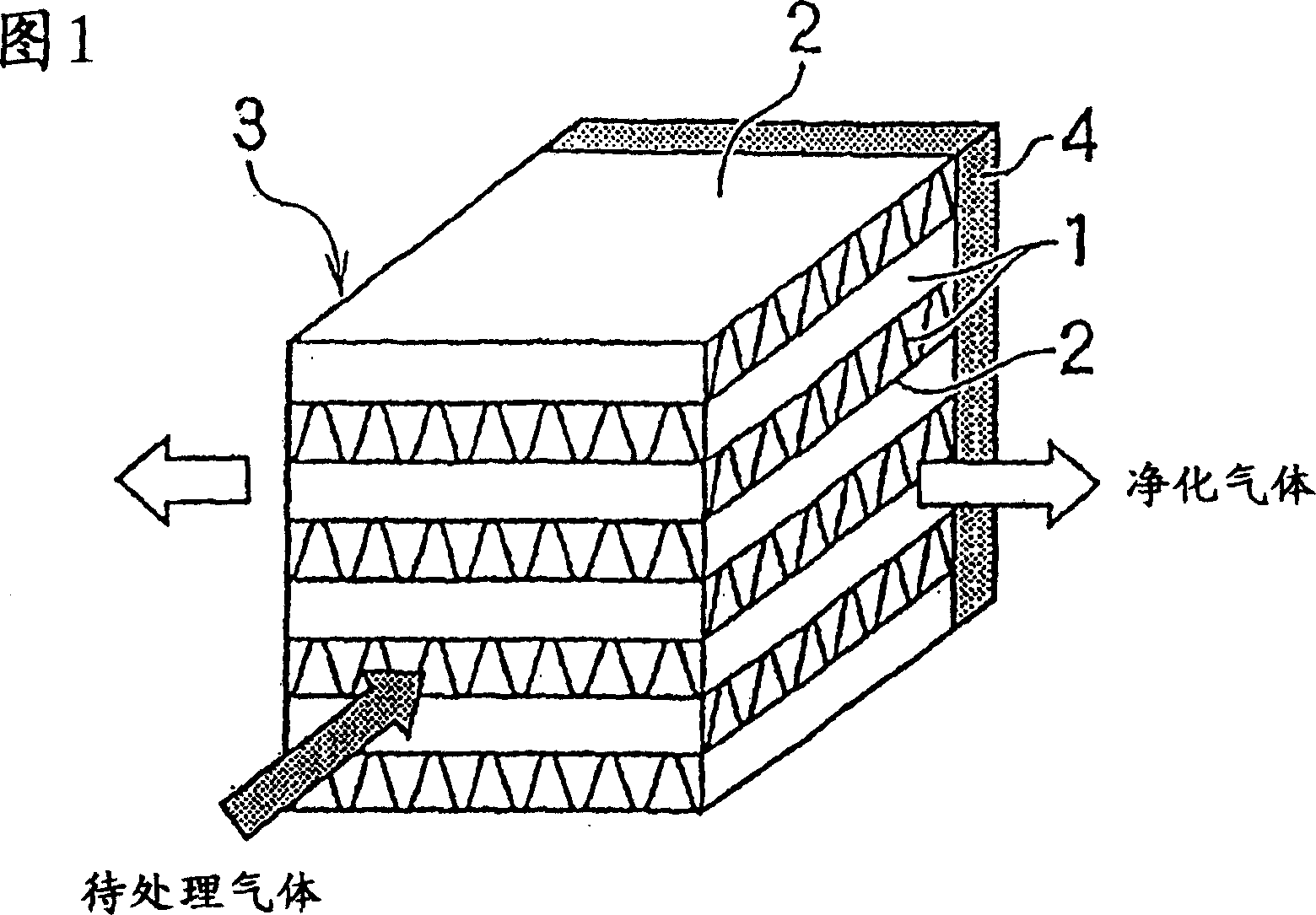

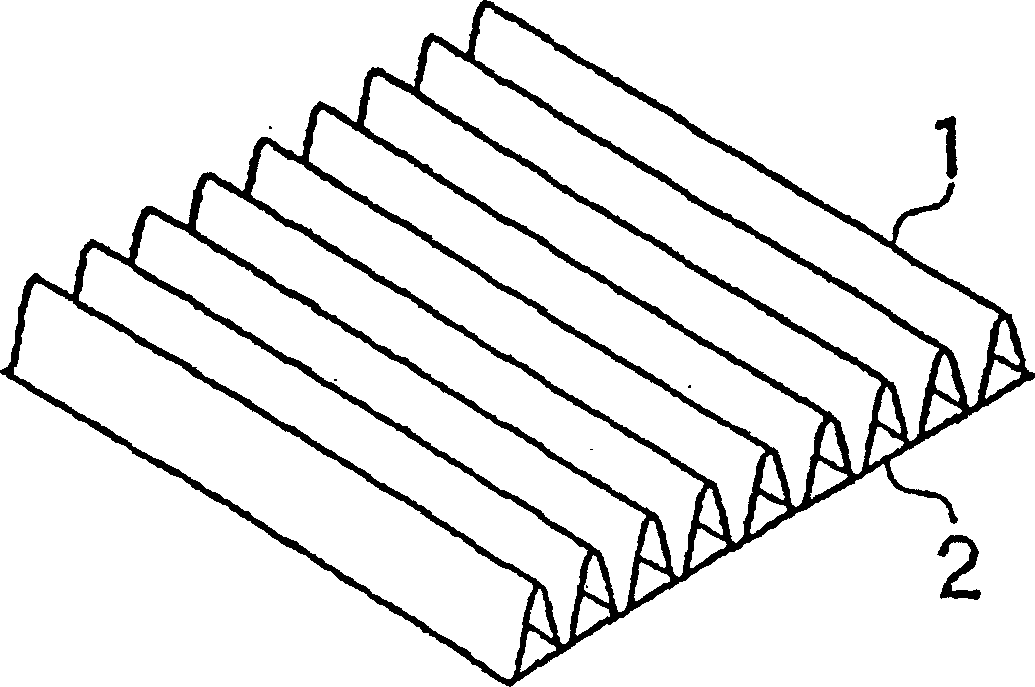

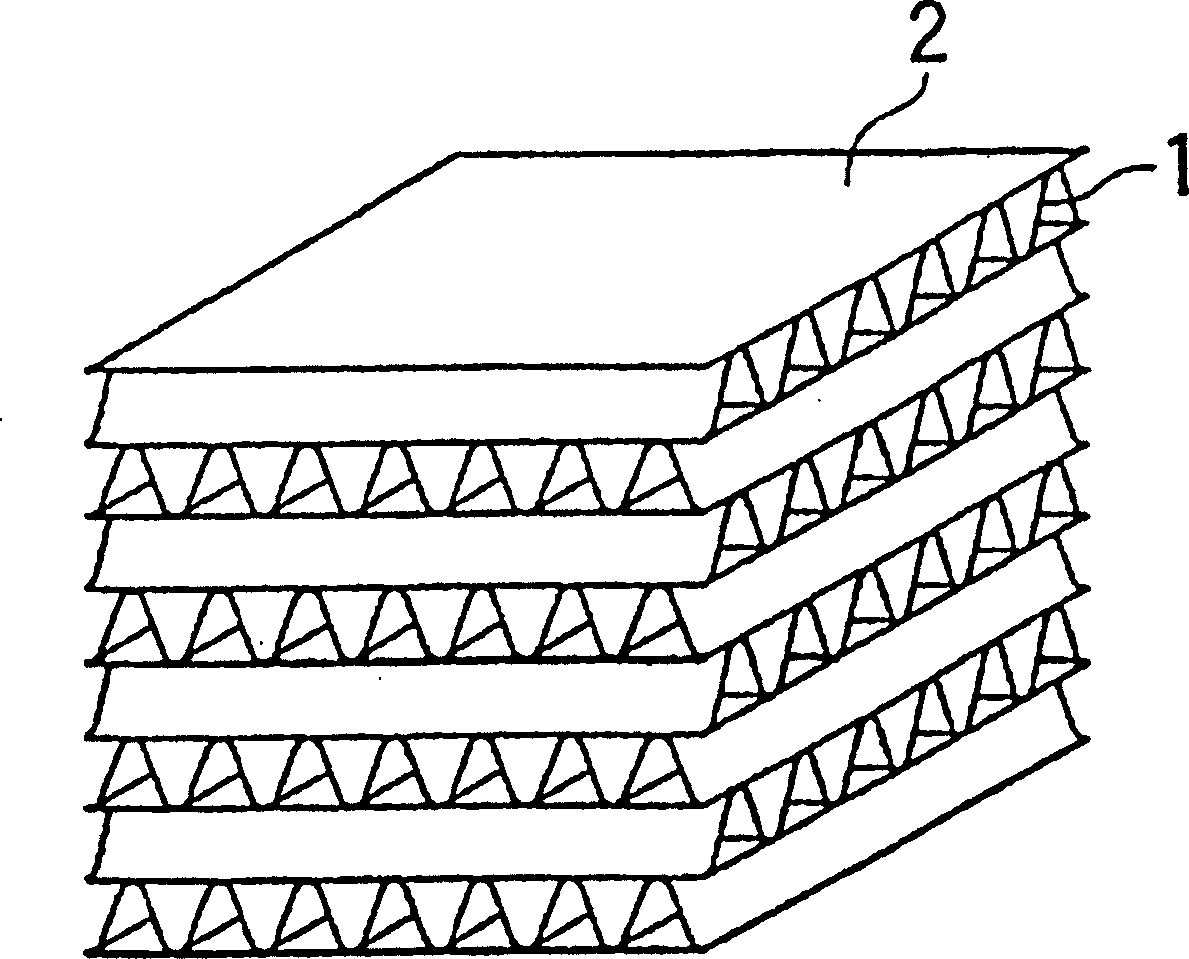

[0068] A stacked block consisting of a 0.2 mm thick perforated corrugated plate and a 0.2 mm thick perforated flat plate is impregnated with a 15% TiO 2 Sol (manufactured by Ishihara Sangyo Co., Ltd.), the plate is made of a nonwoven fabric of silica-alumina fiber (the intersecting corrugated honeycomb is made by NICHIAS Co., corrugated plate pitch: 3.3mm, gap between two flat plates: 1.9mm, external dimensions: 300mm×300mm×300mm), the stacked blocks were air-dried and dried at 150°C. Then, the stacked block was soaked with a dinitrodiammineplatinum solution (Pt concentration: 1.33g / L), dried again and calcined at 600°C to make a substrate for the DPF supporting a 0.2 g / L Pt oxidation catalyst.

example 2

[0070] A substrate for producing a DPF with an oxidation catalyst was produced in the same manner as in Example 1 except that the concentration of dinitrodiammine platinum was changed from 1.33 g / L in Example 1 to 0.32 g / L.

example 3

[0072] By suspending 300 g of TiO in a solution of dinitrodiammine platinum (Pt concentration: 1.7 g / L) 2 Powder (trade name: G5, manufactured by Millennium Pharmaceuticals Co., Ltd., surface area: 320m 2 / g) A slurry prepared was kept at 80°C for 2 hours to allow the Pt component to be absorbed into the TiO 2 s surface. 1 kg of silica gel (trade name: Silicasol-OS, manufactured by Nissan Chemical Industries (Chemical Industry) Co., Ltd., SiO 2 concentration: 20%) was added to 1 kg of the resulting solution, and the pH of the solution was adjusted with a nitric acid solution to obtain a catalyst slurry to be supported in the channel a.

[0073] Prepare a 0.2 mm thick cross-corrugated honeycomb made of a non-woven fabric of silica-alumina fibers (manufactured by NICHIAS Corporation, corrugated plate pitch: 3.3 mm, gap between two flat plates: 1.9 mm, external dimensions : 300mm×300mm×300mm). A method is employed in which the slurry is extracted from Figure 4 Direction A i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com