A safe and efficient marine natural gas hydrate decompression and decomposition production device and method

A hydrate decomposition and hydrate technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of formation energy reduction, hydrate decomposition speed slowdown, formation permeability reduction, etc., to prevent Effects of secondary generation and icing, safe and efficient mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

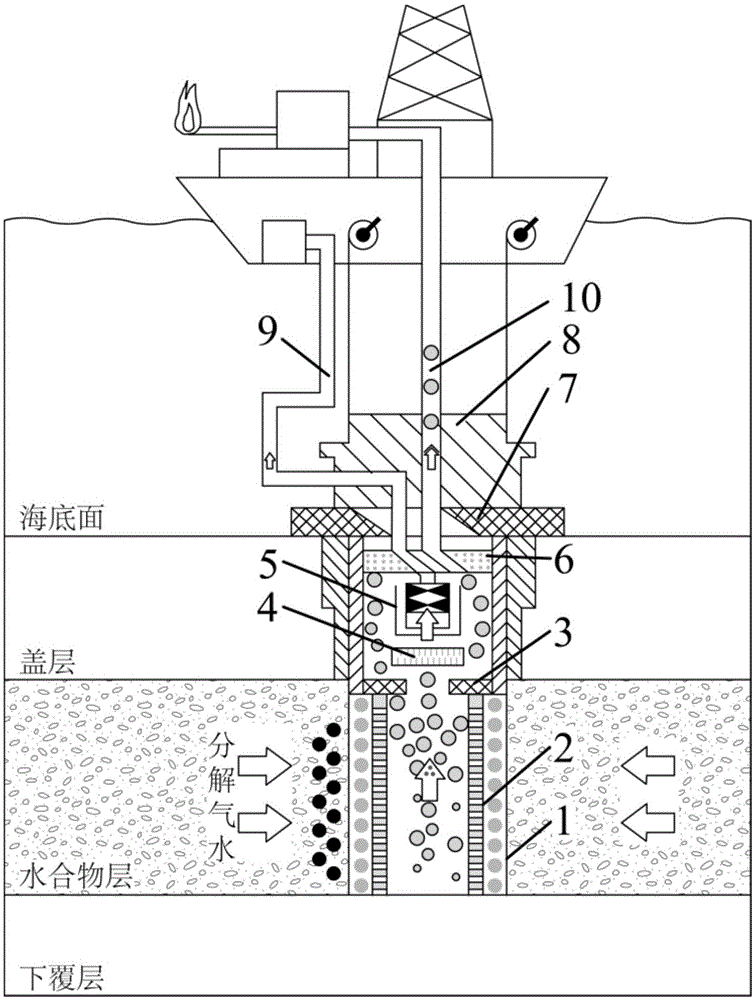

[0024] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0025] 1) Decomposed gas and water flow to the wellbore: After drilling is completed, as the formation pressure decreases, the hydrate layer around the wellbore naturally decomposes into gas and water, and moves to the wellbore. , the gravel packing group 1 blocks the larger particles, and the sand filter casing 2 blocks the smaller particles, so that only the decomposed gas and water flow into the wellbore;

[0026] 2) Gas and water separation: The decomposed gas and water flow upward along the wellbore under the extraction action of the electric submersible pump 5, and the electric heater 4 prevents the secondary generation of hydrate from blocking the electric submersible pump, and passes through the gas-water packer 6 The decomposed gas and water enter the water pipe 9 and the gas pipe 10 respectively, and are finally lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com