Process system and method for plasma gasification of industrial sludge

A technology of industrial sludge and process method, applied in chemical instruments and methods, petroleum industry, sludge treatment, etc., can solve problems such as secondary pollution, heavy metals affecting the surrounding environment, dioxins polluting the atmosphere, etc., to avoid re-generation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

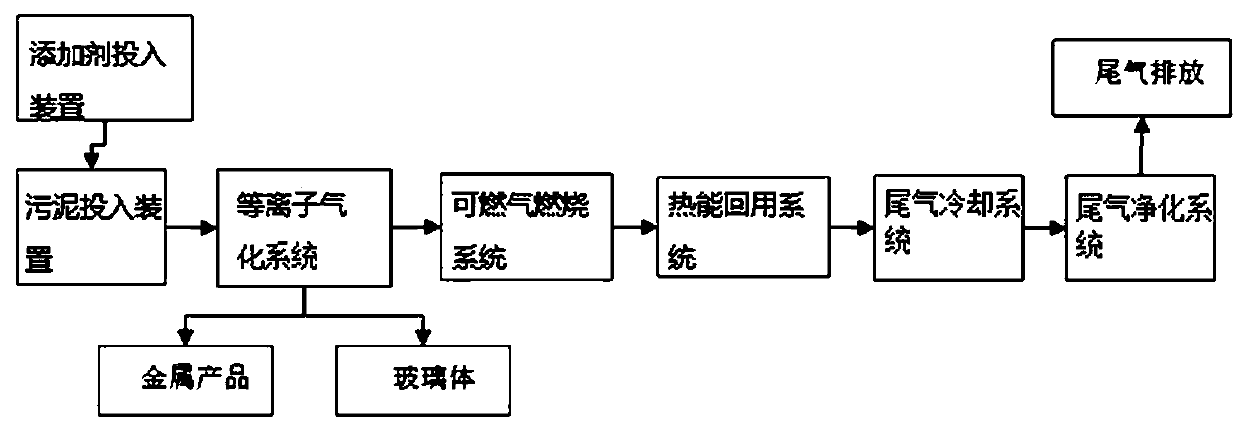

[0030] As a kind of most basic embodiment of the system of the present invention, disclose a kind of process system of plasma gasification of industrial sludge, as figure 1 , including a sludge input device, a plasma gasification system, a combustible gas combustion system, a heat energy recovery system and an exhaust gas treatment system connected in sequence; the sludge input device is connected with an additive input device; the plasma gasification system includes a plasma A gasification furnace; the combustible gas combustion system includes a combustion tower with an oxygen supply pipeline; the tail gas treatment system includes a tail gas cooling system and a tail gas purification system. The dehydrated sludge to be treated is uniformly fed into the plasma gasification system through the sludge feeding device. During the sludge feeding process, the additive feeding device is used to add additives at a uniform rate in proportion. The sludge and additives are mixed evenly ...

Embodiment 2

[0032] As a preferred embodiment of the system of the present invention, a process system for plasma gasification of industrial sludge is disclosed, such as figure 1 , including a sludge input device, a plasma gasification system, a combustible gas combustion system, a heat energy recovery system and an exhaust gas treatment system connected in sequence; the sludge input device is connected with an additive input device; the plasma gasification system includes a plasma Gasifier; the combustible gas combustion system includes a combustion tower with an oxygen supply pipeline; the tail gas treatment system includes a tail gas cooling system and a tail gas purification system, and the tail gas purification system includes a dust removal device, a deodorization device and a desulfurization device . The dehydrated sludge to be treated is uniformly fed into the plasma gasification system through the sludge feeding device. During the sludge feeding process, the additive feeding devic...

Embodiment 3

[0034] As a most basic embodiment of the method of the present invention, a process for plasma gasification of industrial sludge is disclosed, including a sludge pretreatment step, a plasma gasification step, a gas treatment step and a tail gas treatment step;

[0035] In the sludge pretreatment step, the sludge is dehydrated, and the dehydrated sludge is mixed with additives and put into a plasma gasifier;

[0036] In the plasma gasification step, the heat energy generated by the plasma gun in the plasma gasification furnace discharges and arcs under high pressure and heats up to 1200-1600°C. Sludge gasification; at a temperature of 1200-1600 ° C, a small amount of air is introduced to instantly gasify the remaining organic matter (including toxic and harmful organic matter) in the sludge into high calorific value combustible gases such as hydrogen, methane, carbon monoxide, inorganic matter and The additives melt at high temperature to form a glass body.

[0037] The combus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com