Patents

Literature

53results about How to "Prevent respawn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

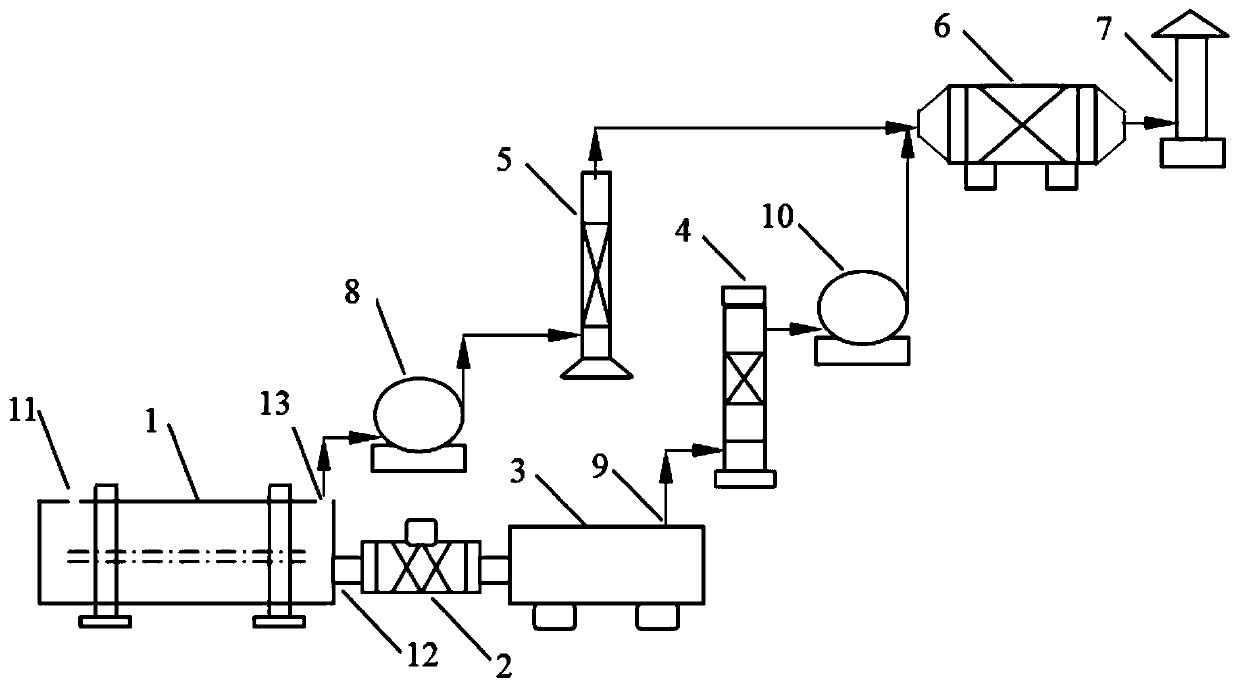

Pyrolysis treatment system for removing organics in chemical abraum salt

ActiveCN111288473ASuppress generationAvoid generatingIncinerator apparatusExhaust fumesEnvironmental engineering

The invention discloses a pyrolysis treatment system for removing organics in chemical abraum salt, and belongs to the field of treatment and disposal of the abraum salt and secondary pollution control. The pyrolysis treatment system comprises a first-level pyrolysis device, a second-level pyrolysis device and a waste gas treatment system, wherein the waste gas treatment system is composed of a quench tower, a spray tower and an organic waste gas purifying device. The chemical abraum salt is subjected to a first-segment low-temperature pyrolysis, moisture, hydrogen chloride and volatile organic pollutants are removed, then second-segment medium-temperature anaerobic pyrolysis is carried out at the temperature lower than salt melting temperature, so that the organics are subjected to pyrolysis to become a gaseous product, and the gaseous product is separated from the abraum salt; and meanwhile, the waste gas generated by the two segments of pyrolysis reaches the standard and is discharged after being treated by the waste gas treatment system. According to the pyrolysis treatment system for removing the organics in the chemical abraum salt, two segments of pyrolysis is used, the organics in the abraum salt can be removed, meanwhile, the pyrolysis temperature is controlled within a temperature interval generated by dioxin, and the purpose of controlling the generation of the dioxin is realized from the source. Therefore, the environmental risk of the abraum salt heat treatment is greatly reduced, and a beneficial route is provided for the recycling of dangerous wastes such aschemical industrial abraum salt.

Owner:HOHAI UNIV

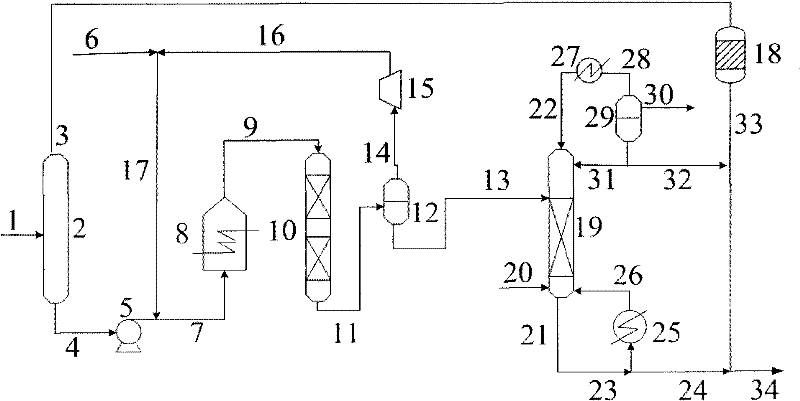

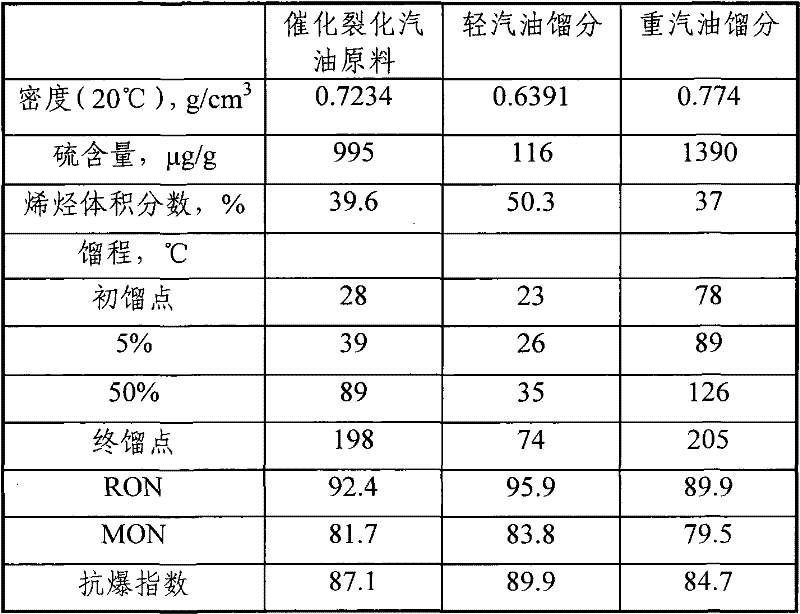

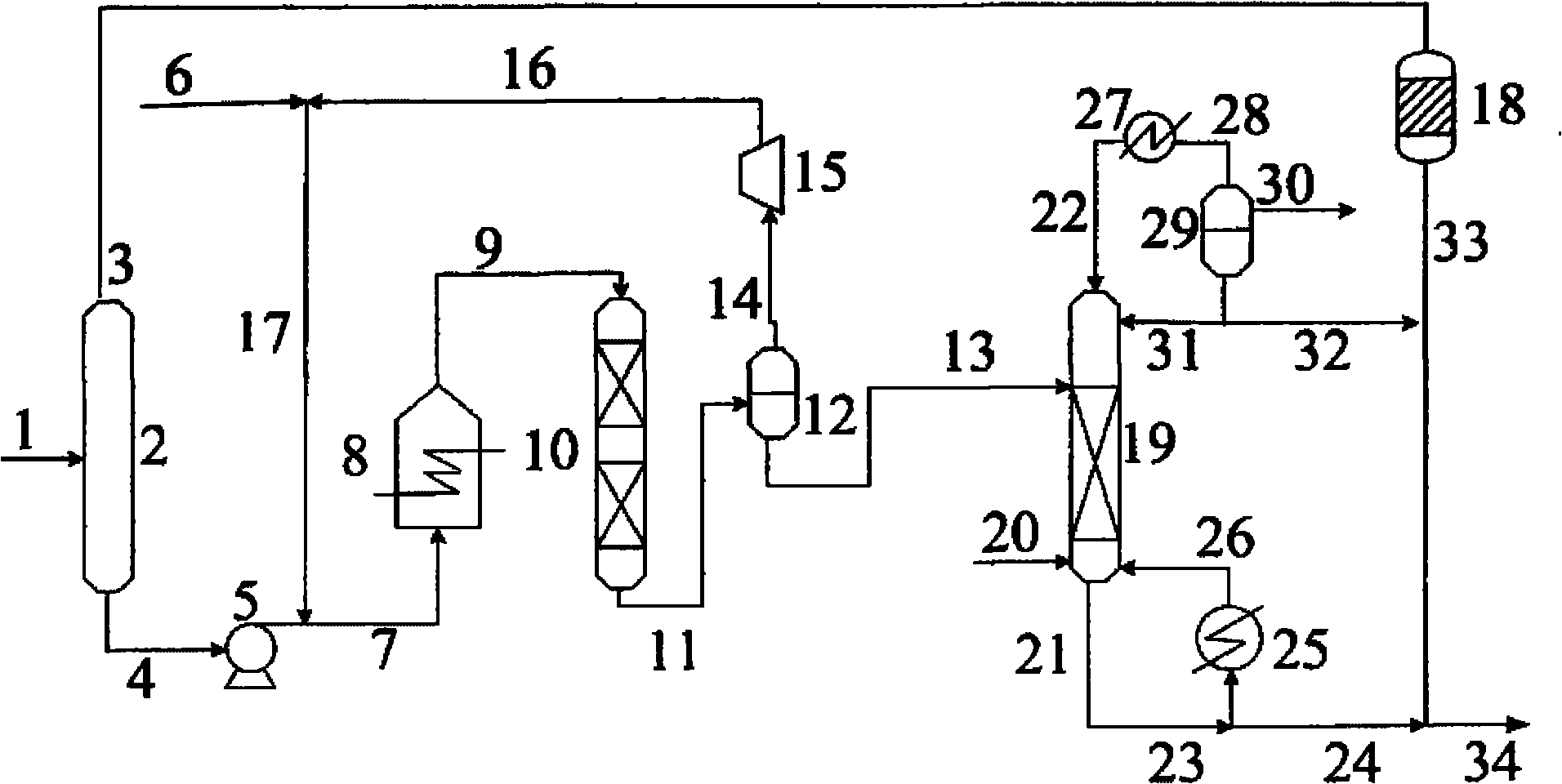

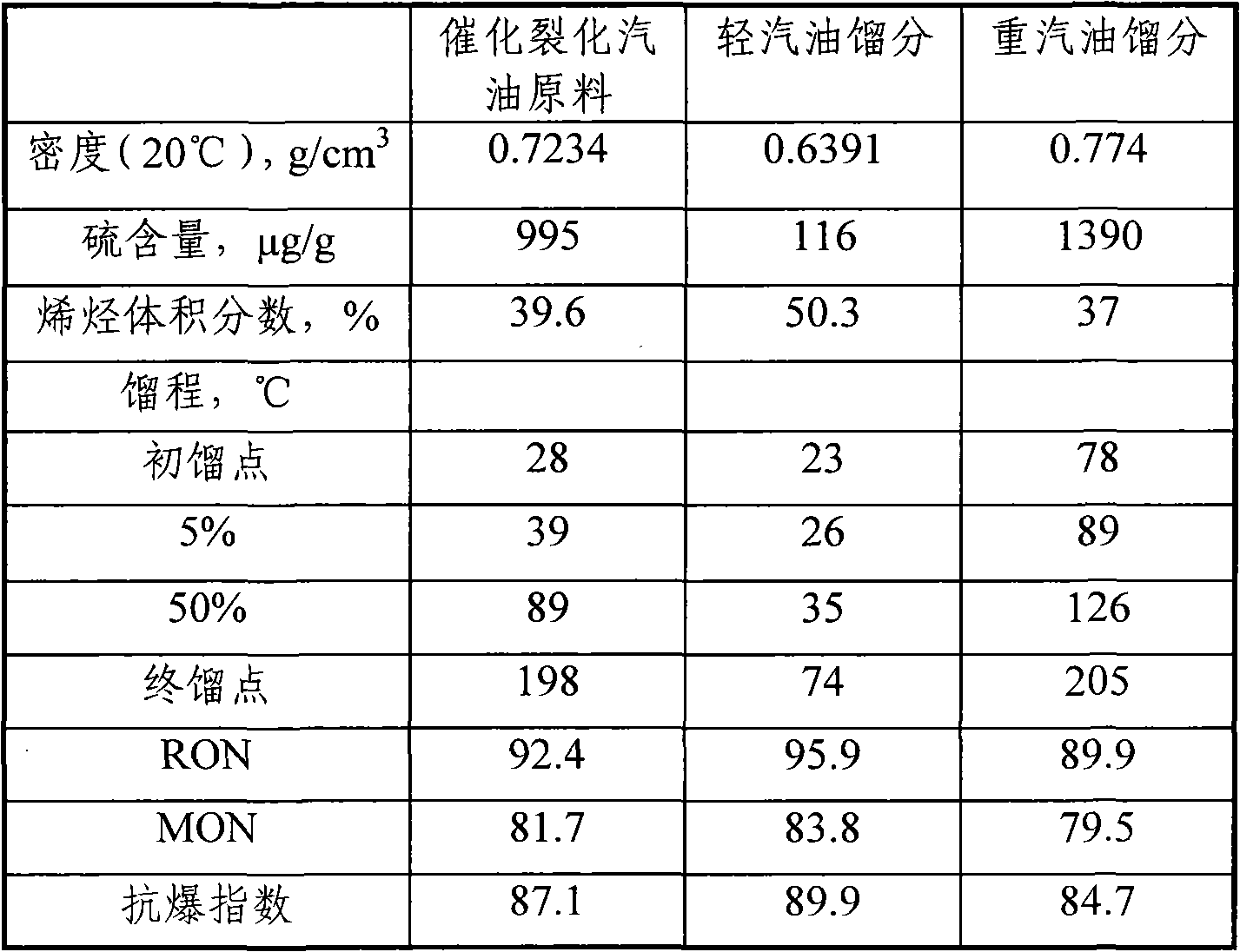

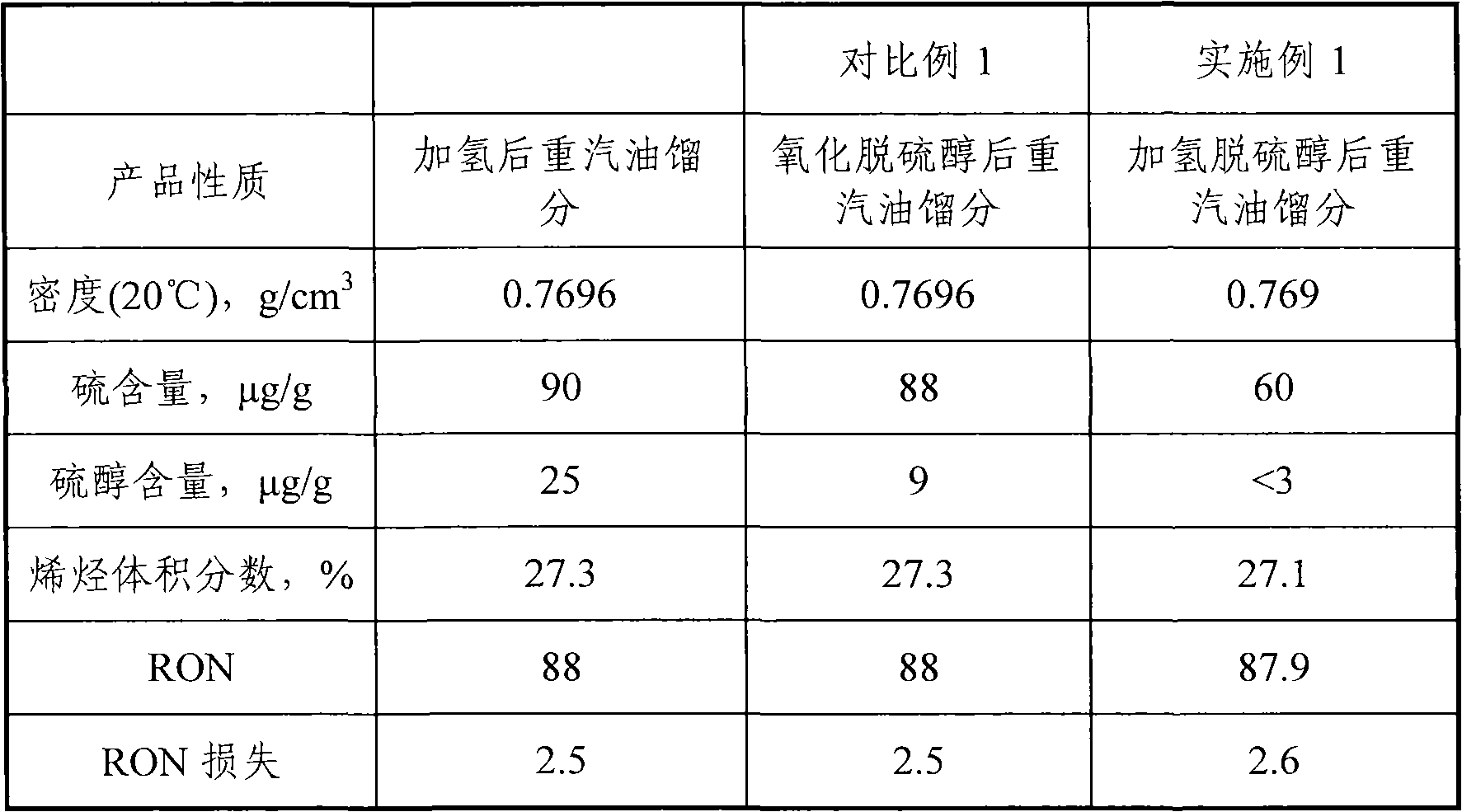

Method for producing low-sulfur gasoline

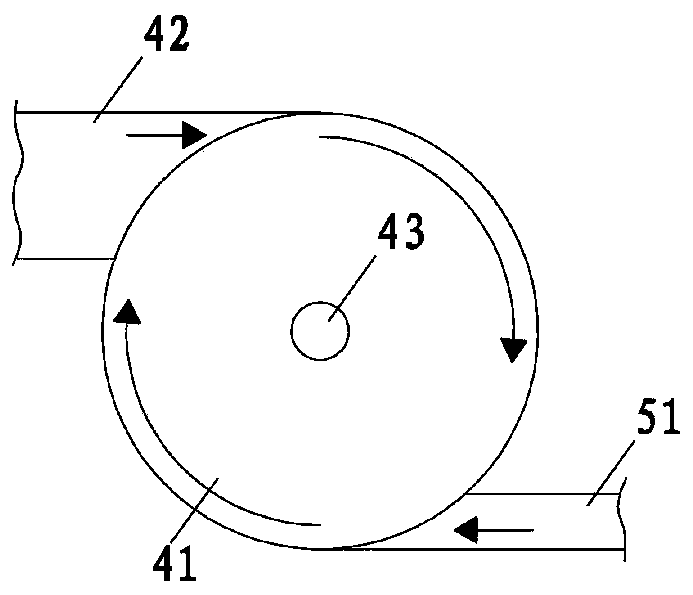

ActiveCN102443433APrevent respawnAvoid Hydrogenation LossTreatment with hydrotreatment processesCounter flowGas phase

The invention relates to a method for producing low-sulfur gasoline, which comprises the following steps that: firstly, gasoline raw materials are fractionated into light and heavy gasoline fractions, the light gasoline fractions are subjected to alkali washing for removing sulfur and alcohol, the heavy gasoline fractions are subjected to catalytic hydrogenation for removing sulfur-containing compounds, the heavy gasoline fractions after the hydrogenation desulfuration are introduced into a counter flow reactor from the middle part, hydrogenation sulfur and alcohol removal catalysts are filled in positions under a material inlet of the counter flow reactor, hydrogen-rich gas is introduced from the bottom of the reactor, a part of heavy gasoline fractions are vaporized into gas phase ingredients and liquid phase ingredients, the liquid phase ingredients flow from top to bottom and are in count flow contact with hydrogen gas on the catalysts for carrying out hydrogenation sulfur and alcohol removal reaction, the liquid phase ingredients after the sulfur and alcohol removal flow out from the bottom of the reactor, the gas phase ingredients and other gas are discharged out from the top of the reactor, the gas phase ingredients after the condensation are mixed with the liquid phase ingredients discharged from the bottom of the tower and the light gasoline fractions subjected to the alkali washing for removing sulfur and alcohol to obtain gasoline products. When the method provided by the invention is adopted, the gasoline product with the sulfur and alcohol sulfur content lower than 3mug / g can be producted, and simultaneously, the total sulfur content of the gasoline product is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Controlled cascade pyrolysis recovery and dioxin prevention and control method for waste salt in chemical industry

ActiveCN111288472AAvoid generatingPrevent respawnIncinerator apparatusChemical industryExhaust fumes

The invention discloses a controlled cascade pyrolysis recovery and dioxin prevention and control method for waste salt in the chemical industry, and belongs to the field of waste salt treatment and secondary pollution control. The method comprises the following steps that firstly, low-temperature pyrolysis is performed on the waste salt to remove moisture and low-boiling-point organic matters inthe waste salt, and then high-temperature anaerobic pyrolysis is performed, and recovery is performed to obtain organic matter removed salt; meanwhile, pyrolysis waste gas is treated by a waste gas treatment system and is discharged after reaching the standard. According to the controlled cascade pyrolysis recovery and dioxin prevention and control method for waste salt in the chemical industry, the waste salt containing the organic matter is subjected to low-temperature and high-temperature two-stage controlled pyrolysis, high-temperature pyrolysis gas is subjected to quenching, generation ofdioxin and oxidizing gases such as nitrogen oxides and sulfur oxides is effectively avoided, therefore, the purposes that the waste salt is pyrolyzed to remove the organic matter, harmlessness and recycling are achieved, and generation of dioxin is controlled from the source are achieved. The method is high in organic matter removal rate, the generation of dioxin can be controlled from the source, the treatment and disposal cost of the waste salt and the environmental risk are greatly reduced, the method is controllable, and a beneficial path is provided for recycling hazardous wastes such asthe waste salt in the chemical industry.

Owner:HOHAI UNIV

Stainless steel pickling passivator and preparation method thereof

InactiveCN107012472AAvoid harmGood for healthMetallic material coating processesFatty alcoholMaterials science

The invention discloses a stainless steel pickling passivator and a preparation method thereof. The stainless steel pickling passivator comprises citric acid, hydrochloric acid, formic acid, fatty alcohol-polyoxyethylene ether, polyethyleneimine, epoxy octyl stearate, thiosemicarbazide, epoxy chloropropane, hydrogen peroxide, a penetrating agent, a corrosion inhibitor, a thickening agent, an inorganic filler and a viscosity modifier. The preparation method comprises the steps of firstly adding part of raw materials such as the fatty alcohol-polyoxyethylene ether and the like into the hydrochloric acid sequentially, and uniformly stirring the raw materials to obtain a mixed solution I; then sequentially adding part of the raw materials such as the hydrogen peroxide into mixed acid liquor of the citric acid and the formic acid, and uniformly stirring the raw materials to obtain a mixed solution II; then mixing the mixed solution I and the mixed solution II, and adding the inorganic filler into the mixture; and finally adding the penetrating agent, the corrosion inhibitor, the thickening agent and the viscosity modifier sequentially into the mixture, and uniformly mixing the mixture to obtain the finished product. According to the stainless steel pickling passivator and the preparation method thereof, the stainless steel pickling passivator is good in passivation effect, not prone to damage the surface of stainless steel, environment-friendly and simple to prepare and does not cause harm to human bodies and environment.

Owner:合肥协耀玻璃制品有限公司

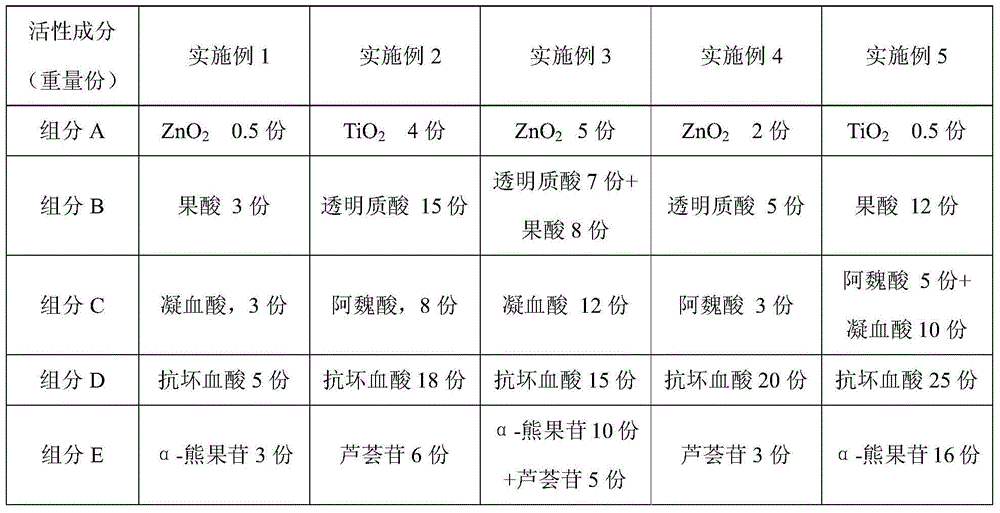

Spot-removing essence emulsion and preparation method thereof

ActiveCN104127330APrevent oxidationFreckle removal effect is goodCosmetic preparationsToilet preparationsAdditive ingredientTranexamic acid

The invention relates to a spot-removing essence emulsion. Active ingredients of the spot-removing essence emulsion comprise 0.5-8 parts of an ingredient A selected from zinc dioxide and titanium dioxide, 3-15 parts of an ingredient B selected from hyaluronic acid and tartaric acid, 3-15 parts of an ingredient C selected from tranexamic acid and ferulic acid, 5-25 parts of an ingredient D selected from ascorbic acid and 3-16 parts of an ingredient E selected from arbutin and barbaloin. The spot-removing essence emulsion is obtained by mixing emulsification of water-in-oil microemulsions comprising the ingredients C, D and E, an oil-in-water emulsion comprising the ingredient A, a coated emulsion comprising the ingredient B and a colorant. The spot-removing essence emulsion is designed based on a skin cell directional penetration technology (5XCell-Technology) and realizes directional penetration and layer-by-layer action of different active ingredients in different skin cell layers thereby producing substantial spot removing efficacy.

Owner:上海雷霆生物科技股份有限公司

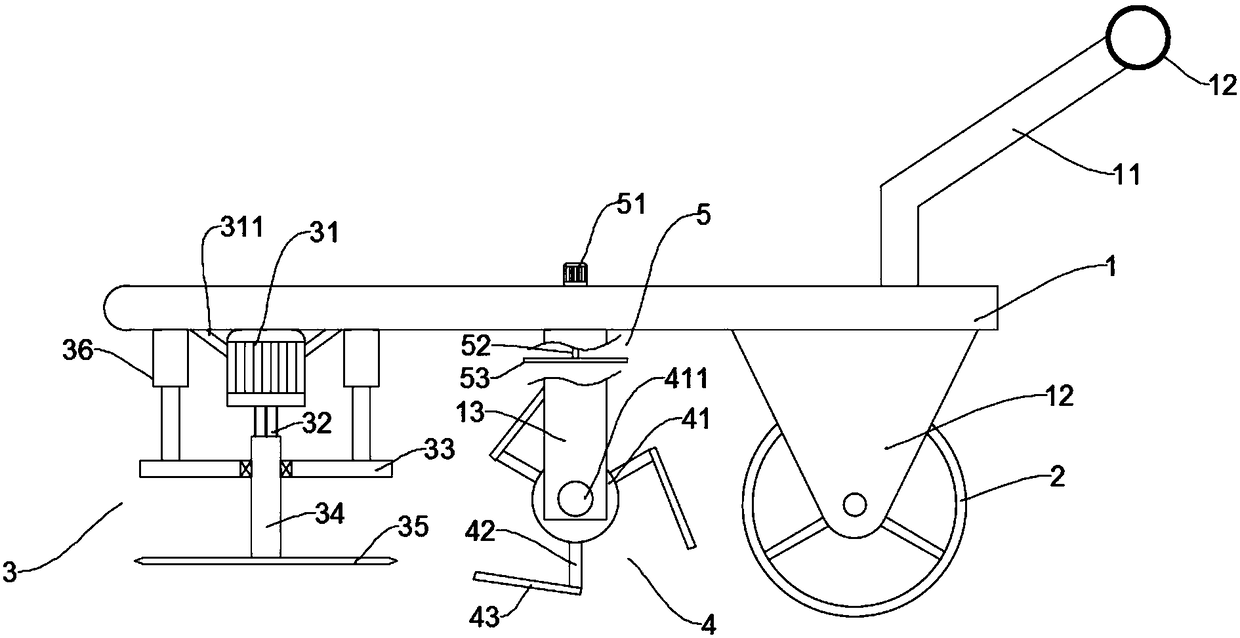

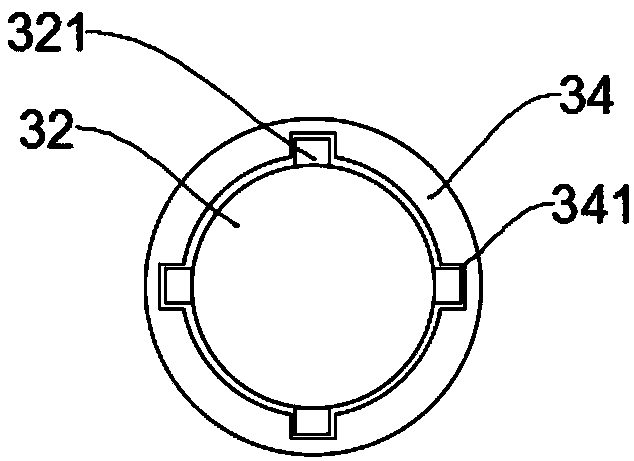

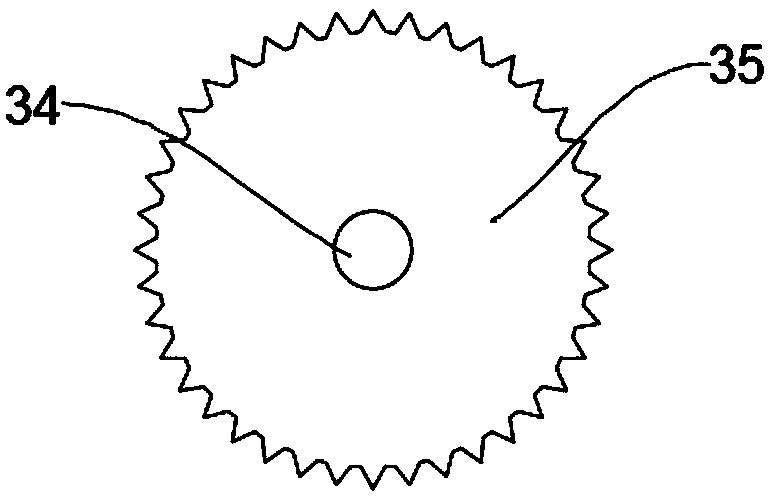

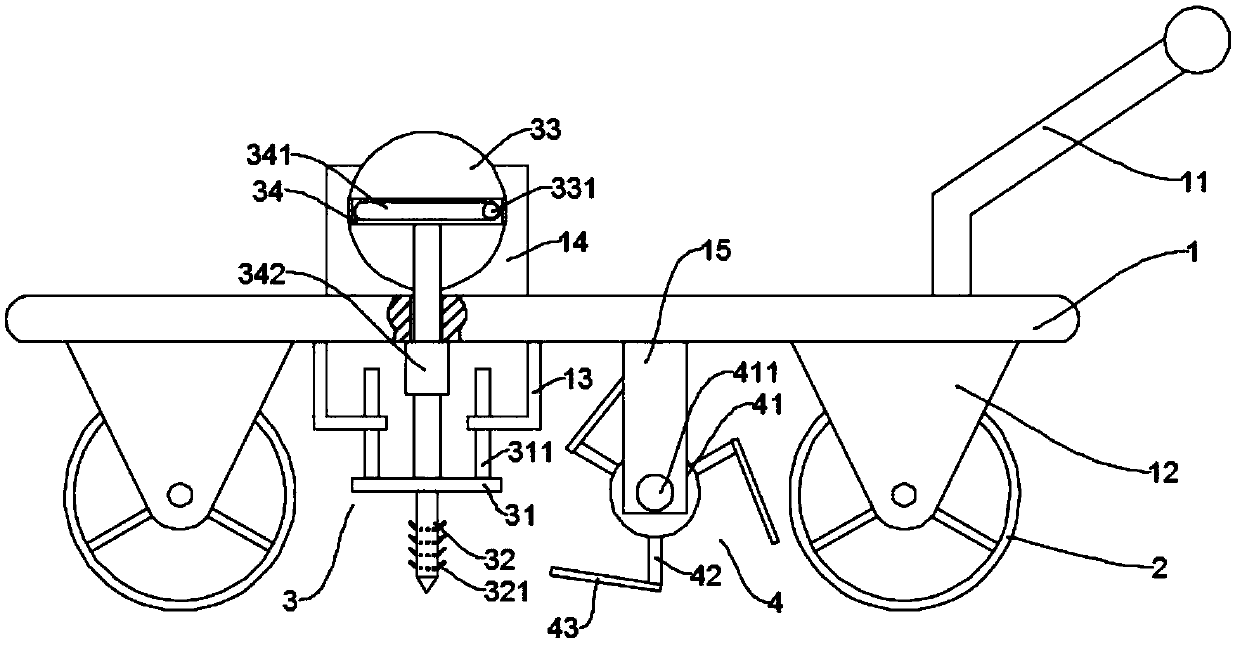

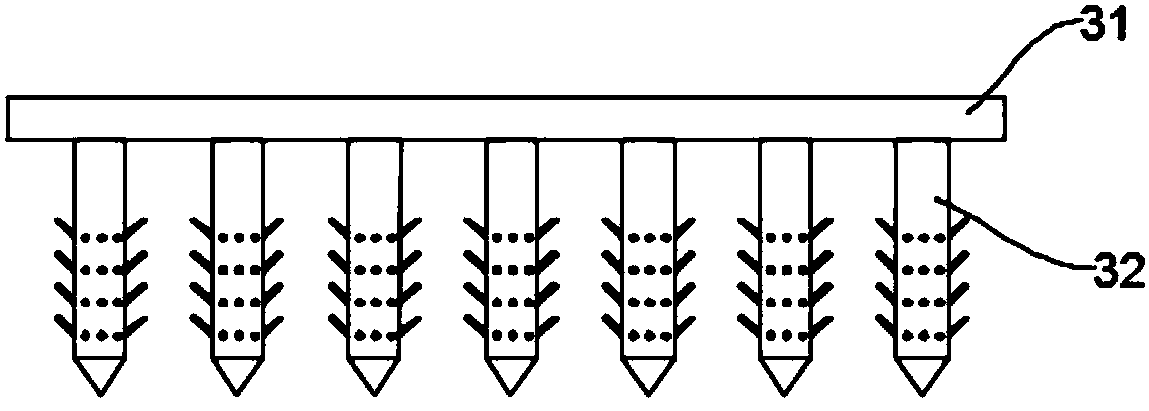

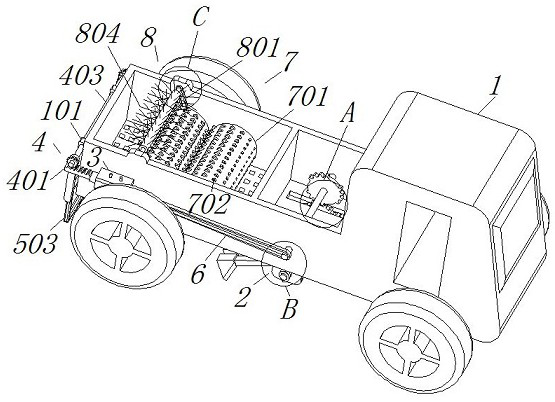

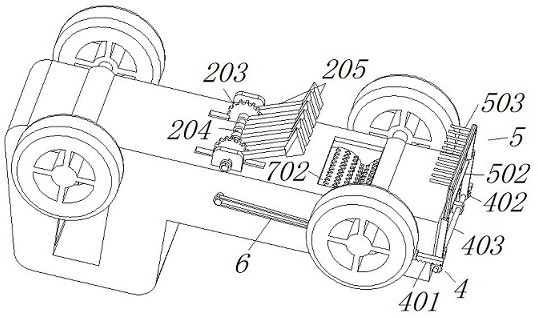

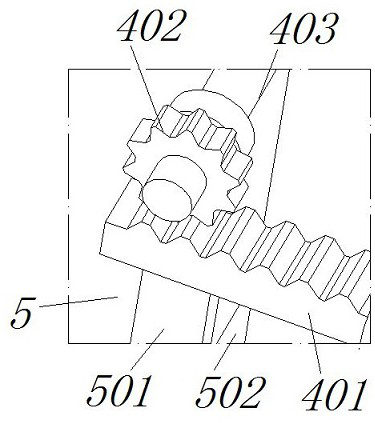

Lawn mower with root removal mechanism

The invention discloses a lawn mower with a root removal mechanism. The lawn mower comprises a base, a mowing mechanism, the root removal mechanism and a cleaning mechanism; a hand holding frame is fixed at the rear side of the top of the base, an installation frame is fixed at the rear side of the bottom of the base, and rollers are installed on the installation frame; the mowing mechanism is arranged on the front side of the bottom of the base; the root removal mechanism is arranged on the rear side of the bottom of the base; the cleaning mechanism comprises a cleaning motor. When the lawn mower is operated, weeds are mowed by the mowing mechanism, so that only rhizomes with certain lengths of weeds are left on the surface of the ground, the rhizomes of the weeds are removed from soil bythe root removal mechanism to achieve deep cleaning of the weeds, the regeneration of the weeds is avoided, cleaning of the rhizomes of the weeds on a clamping plate is conducted by the cleaning mechanism, and the root removal mechanism can be constantly operated.

Owner:奉节县畅瑞中药材种植有限公司

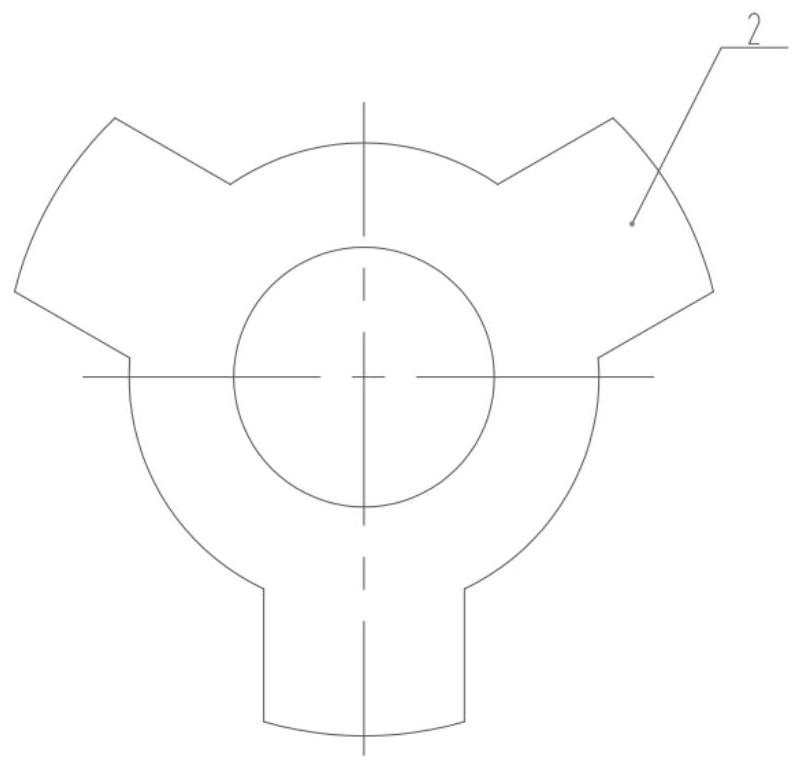

Novel weed pulling-out device used for garden industry

The invention discloses a novel weed pulling-out device used for the garden industry. The device comprises a base, a soil-loosening assembly and a weed pulling-out assembly. The back side of the top of the base is fixed with a hand-held rack. Left and right sides of the base are symmetrically connected with wheel supports, on which rollers are installed. The soil-loosening assembly and the weed pulling-out assembly are arranged at the position between the rollers on two sides of the bottom of the base. The soil-loosening assembly is located on the front side of the weed pulling-out assembly. The novel weed pulling-out device used for the garden industry is novel in structure and simple in operation. By arranging the weed pulling-out assembly, weeds can be rooted out in order to effectivelyprevent weeds from growing again. By arranging the soil-loosening assembly, soil is loosened before weed pulling-out. Therefore, the weed pulling-out assembly can be operated in a more labor-saving manner. Meanwhile, clamp gaps with different opening sizes are arranged in a weed pulling-out plate so that the weed pulling-out plate can act upon weed rootstocks with different external diameters andsizes, thereby increasing the success rate of weed pulling-out.

Owner:SHENZHEN SHENGXIANG INTPROP CO LTD

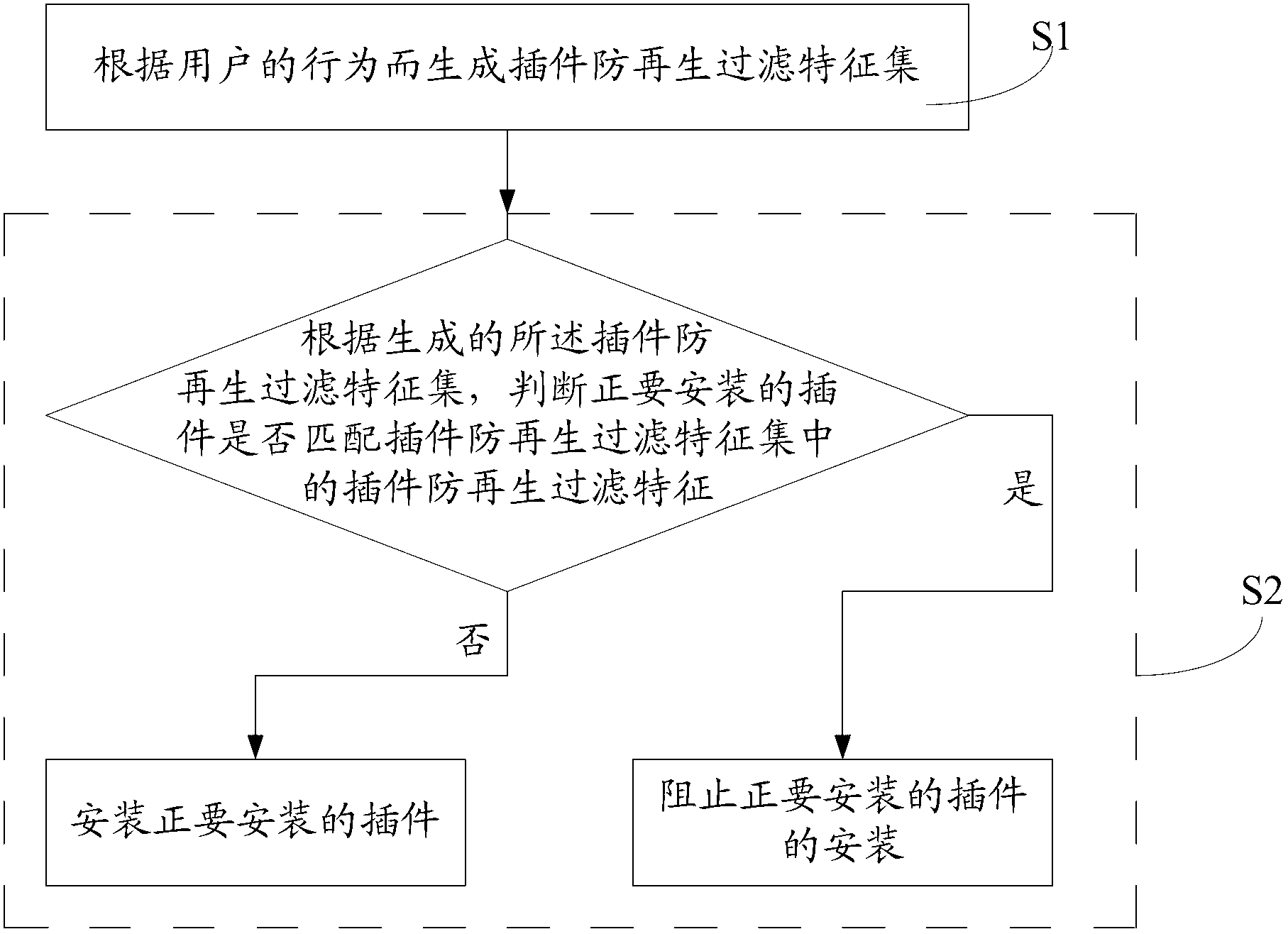

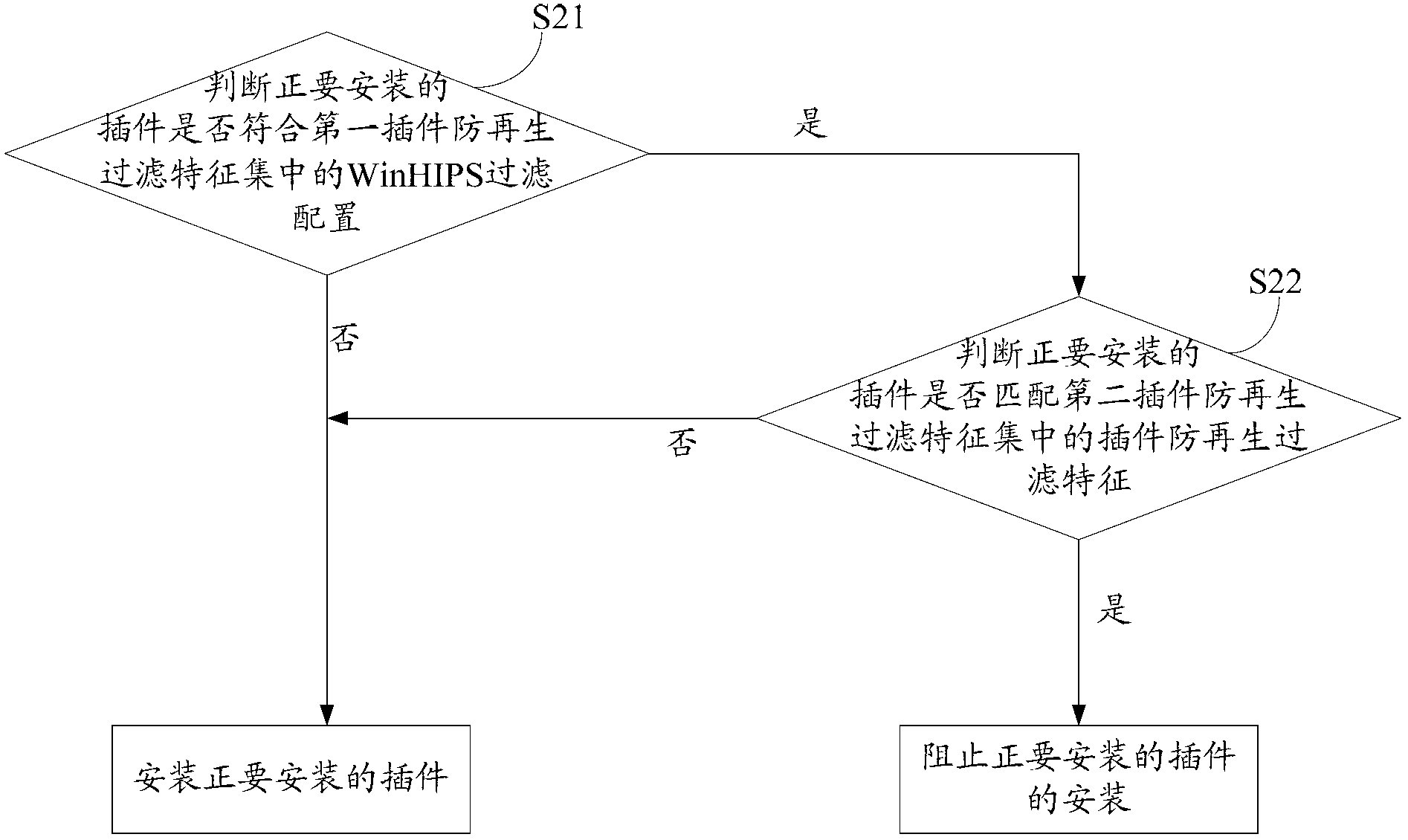

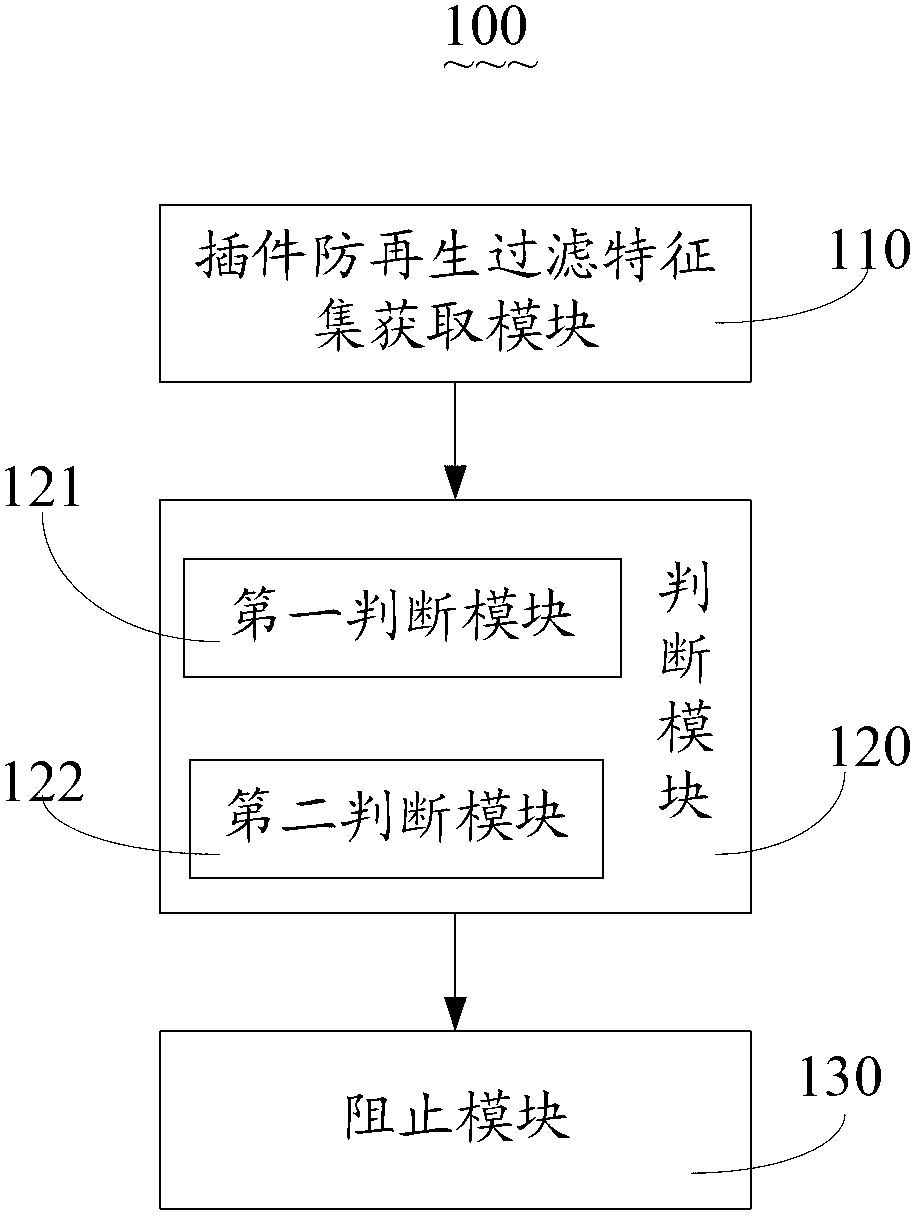

Pug-in anti-regeneration method and corresponding plug-in anti-regeneration system

ActiveCN102799835AInstallation blockEasy to usePlatform integrity maintainanceData switching networksFeature setEngineering

The invention relates to a plug-in anti-regeneration method. The method comprises the following steps of: acquiring a plug-in anti-regeneration filter feature set; judging whether a plug-in which is to be installed is matched with a plug-in anti-regeneration filter feature in the plug-in anti-regeneration filter feature set; and stopping the installation of the plug-in which is to be installed when the plug-in is matched with the plug-in anti-regeneration filter feature. The invention also provides a corresponding plug-in anti-regeneration system. By the plug-in anti-regeneration method and the plug-in anti-regeneration system, the regeneration of plug-ins can be prevented, and users can conveniently use computers.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Stainless steel passivation liquid and passivation technology thereof

InactiveCN106939420AAvoid harmNo harmMetallic material coating processesAcetic anhydrideSand blasting

The invention discloses stainless steel passivation liquid and a passivation technology thereof. The stainless steel passivation liquid comprises, by weight, 40-50 parts of inorganic acid, 5-15 parts of hydrogen peroxide, 8-12 parts of cyclohexanol, 4-8 parts of 2-ethylhexyl epoxystearate, 4-6 parts of acetic anhydride, 2-4 parts of polyethyleneimine, 3-5 parts of carbomer resin, 2-4 parts of a penetrating agent, 1-3 parts of corrosion inhibitor and 10-20 parts of organic filler. The passivation technology of the stainless steel passivation liquid comprises polishing and rust removal, surface oil removal, first-time water washing, sand blasting, acid pickling passivation, second-time water washing and surface drying. The stainless steel passivation liquid is little in perniciousness, good in passivation effect and not prone to generating corrosive damage on a stainless steel product. The passivation technology is simple, operation is easy, the production cost is low, pollution to the environment is weak, and the standard of green and environment friendliness is met.

Owner:合肥协耀玻璃制品有限公司

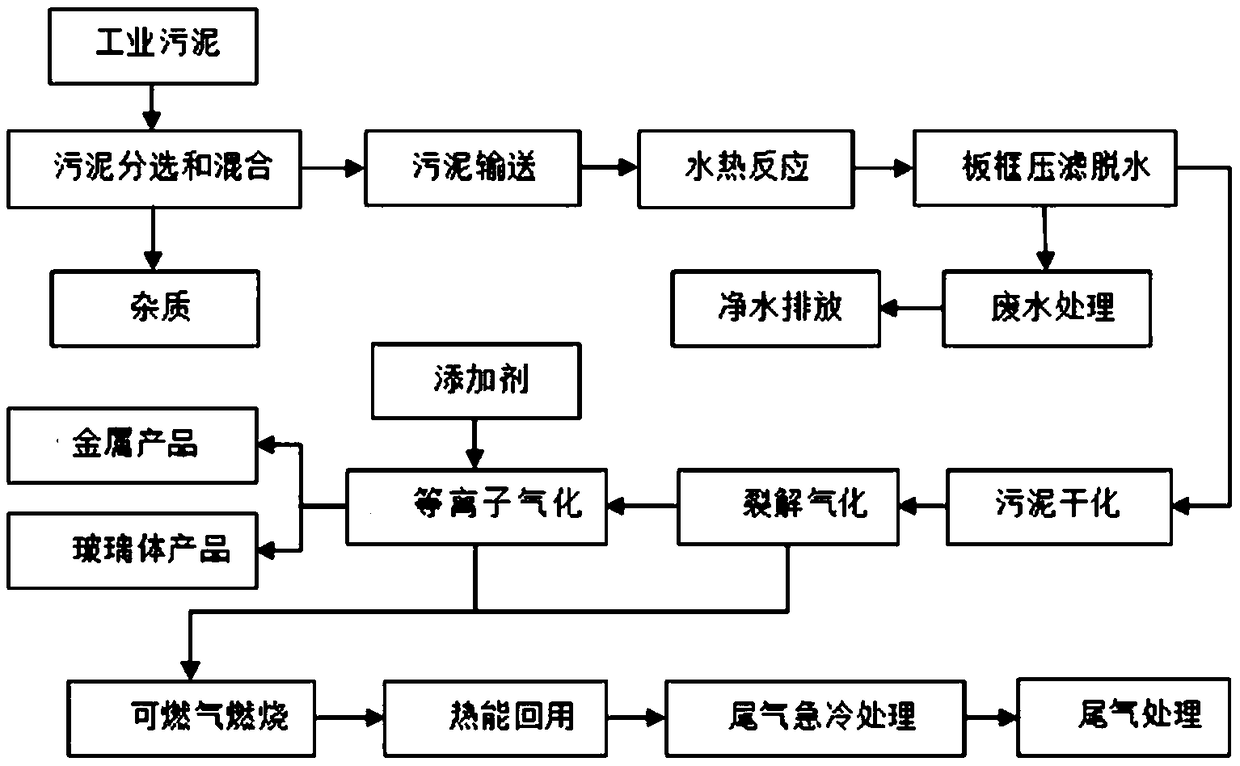

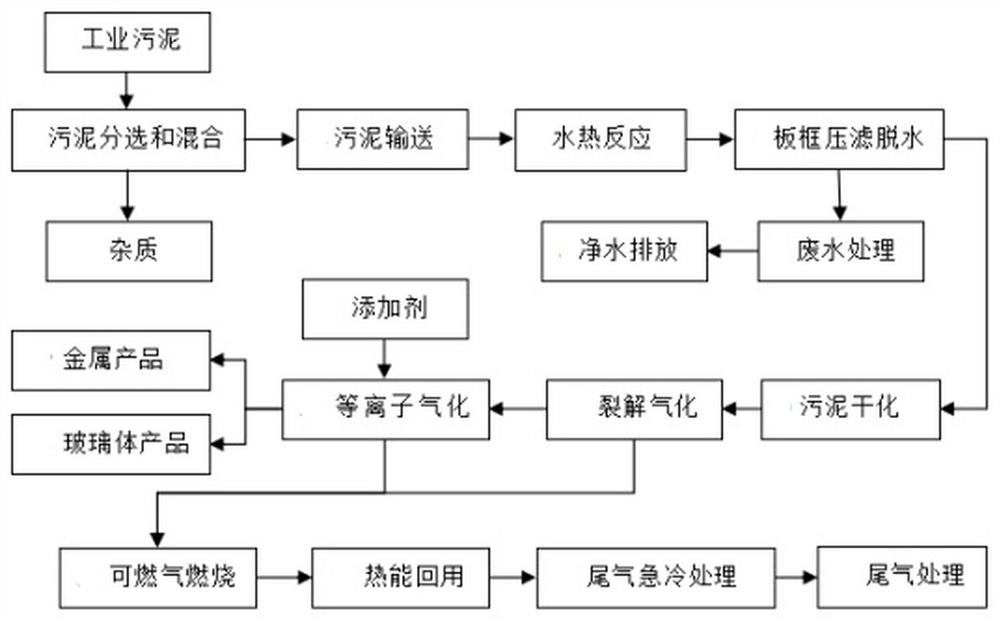

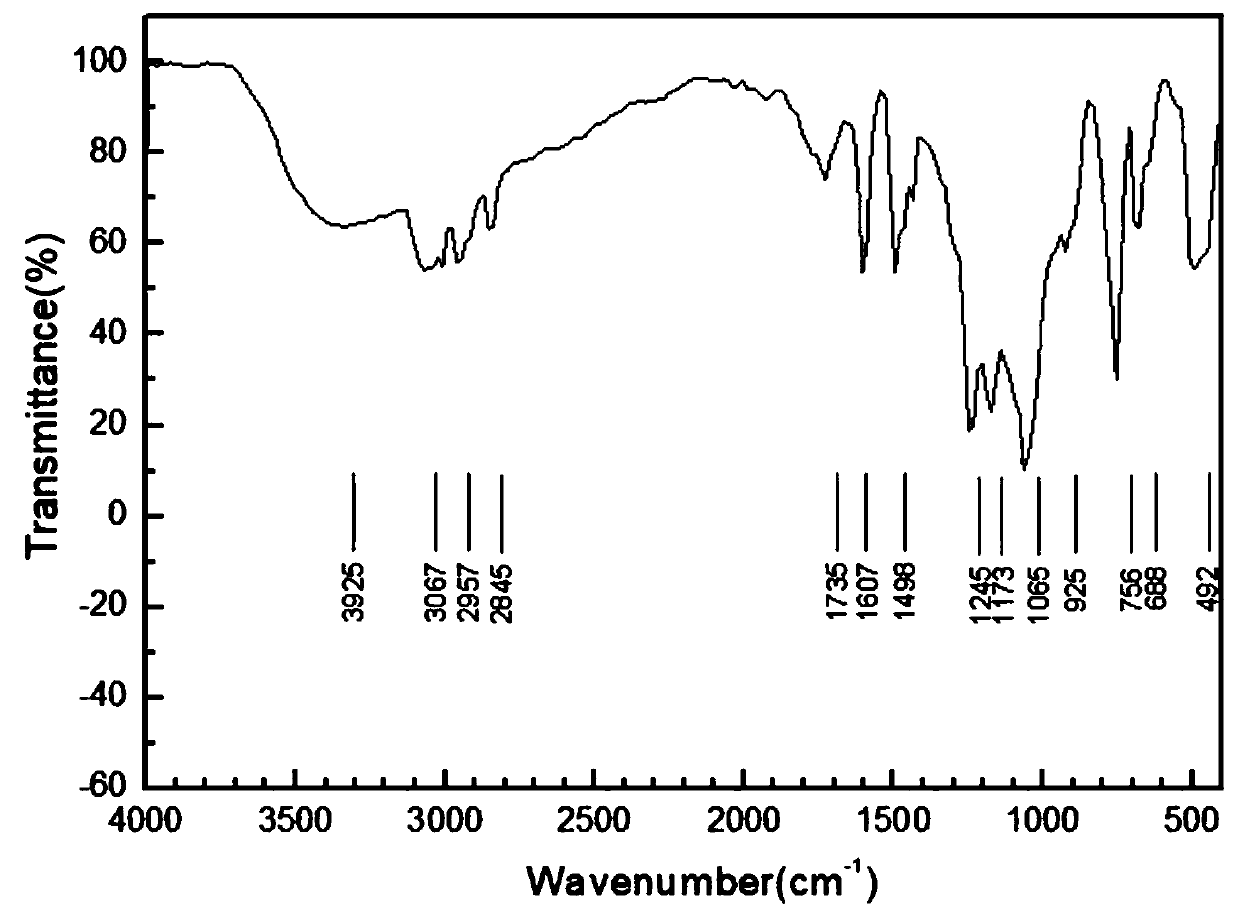

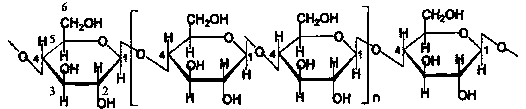

Industrial sludge recycling method

ActiveCN108840544AReduce damageEnsure continuous safe and stable operationSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesHeavy metalsPyrolysis

The invention discloses an industrial sludge recycling method, and belongs to the technical field of industrial sludge harmless treatment. The industrial sludge recycling method comprises the steps ofsludge sorting and mixing, sludge conveying, hydrothermal reaction, plate-frame pressure filtration and dewatering, sludge drying, pyrolysis, plasma gasification and tail gas treatment. The industrial sludge recycling method can effectively use a heat value of sludge, recycle potential heat energy in the sludge, recycle metal parts, melt residual inorganic matters into glass bodies which cover residual heavy metals to serve as building materials, avoid harms caused by the heavy metals entering water and basically implement zero discharge of pollutants.

Owner:CHENGDU YUANYONG TECH DEV

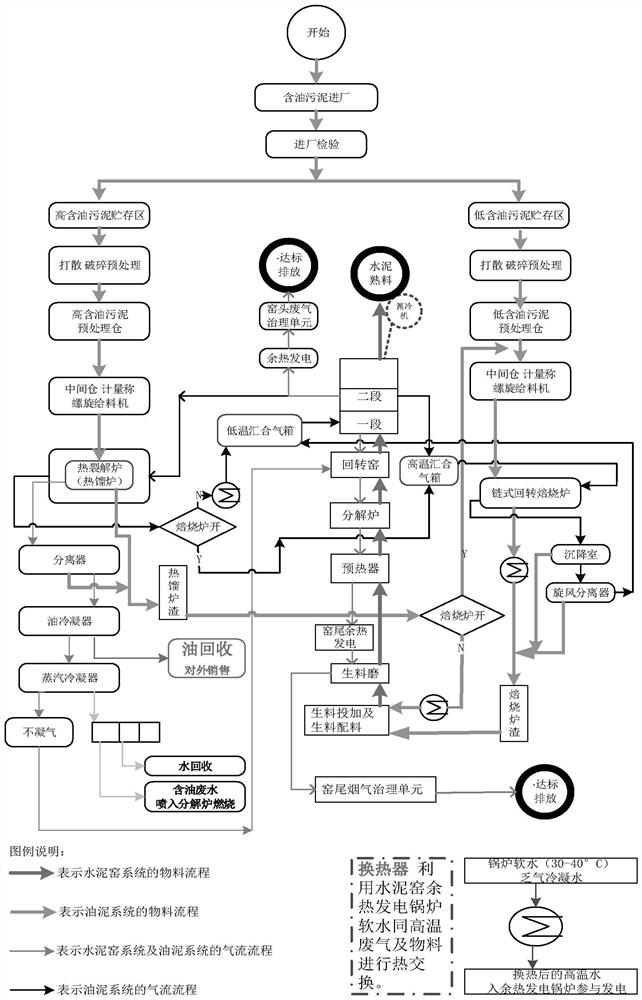

Device and method for resource utilization and harmless treatment of oily sludge

PendingCN113121082ASafe and efficient to useReduce heat consumption costsSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningThermodynamicsSludge

The invention discloses a device and method for resource utilization and harmless treatment of oily sludge. The method comprises the following steps: carrying out scattering and crushing pretreatment on high-oil-content sludge with an oil content of more than or equal to 5%, then carrying out thermal cracking to recover oil, and burning generated non-condensable gas in a cement kiln, subjecting generated thermal cracking furnace slag with an organic matter content of less than 0.5% to heat exchange, and then putting the thermal cracking furnace slag into a raw material system the cement kiln; carrying out scattering and crushing pretreatment on low-oil-content sludge with an oil content of less than 5%, performing roasting treatment on the low-oil-content sludge and thermal cracking furnace slag with an organic matter content of more than or equal to 0.5%, carrying out heat exchange on the generated roasting furnace slag, putting the generated roasting furnace slag into a cement raw material system, and treating the generated roasting furnace waste gas in the cement kiln. According to the invention, the traditional resource utilization and cement kiln co-processing mode of the oily sludge is innovatively changed through a system integration process, oil recovery is realized, large-scale co-processing of the oily sludge in the cement kiln is realized through raw material addition, and the method has the characteristics of wide application range, full resource utilization, thorough and harmless treatment and the like.

Owner:四川海沛环保科技有限公司

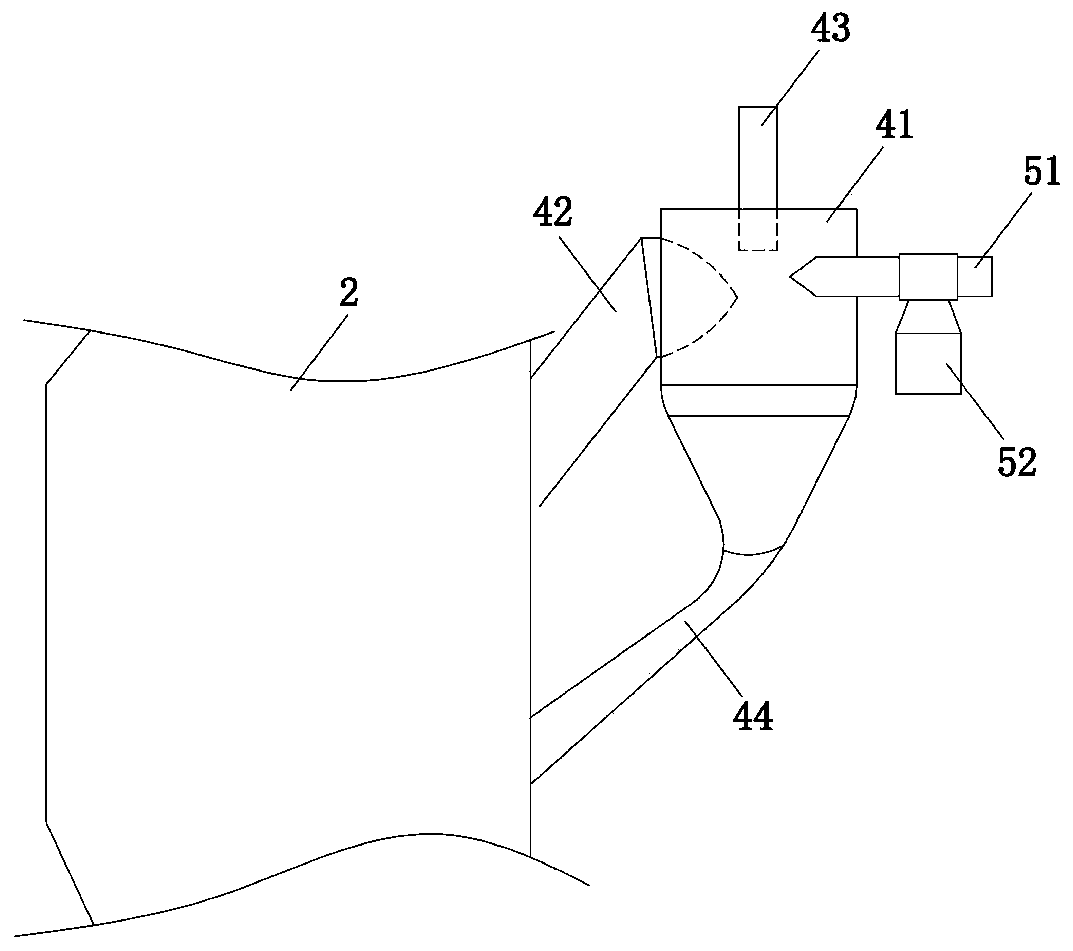

Agricultural automatic weeding and insecticide spraying device

InactiveCN110521706AAchieve uprootingPrevent respawnWeed killersInsect catchers and killersSpray nozzleBiology

The invention relates to the field of agricultural planting, in particular to an agricultural automatic weeding and insecticide spraying device. The agricultural automatic weeding and insecticide spraying device comprises a machine body, a pesticide spraying device is arranged on the left side of the machine body and comprises a pesticide addition cavity, a pesticide storage cavity is formed belowone pesticide spraying nozzle, another pesticide spraying nozzle is arranged below the pesticide storage cavity, a first working cavity is formed in the right side of the pesticide storage cavity, aweeding rotating drum is arranged in the first working cavity, and a weeding iron sheet is arranged above the weeding rotating drum. The agricultural automatic weeding and insecticide spraying devicecan achieve automatic weeding and pesticide spraying after weeding and can automatically collect removed weeds, the weeds do not need to be manually collected, and manual work after weeding is avoided.

Owner:SHAOXING SHANGYU YUANBIN AUTOMATION CO LTD

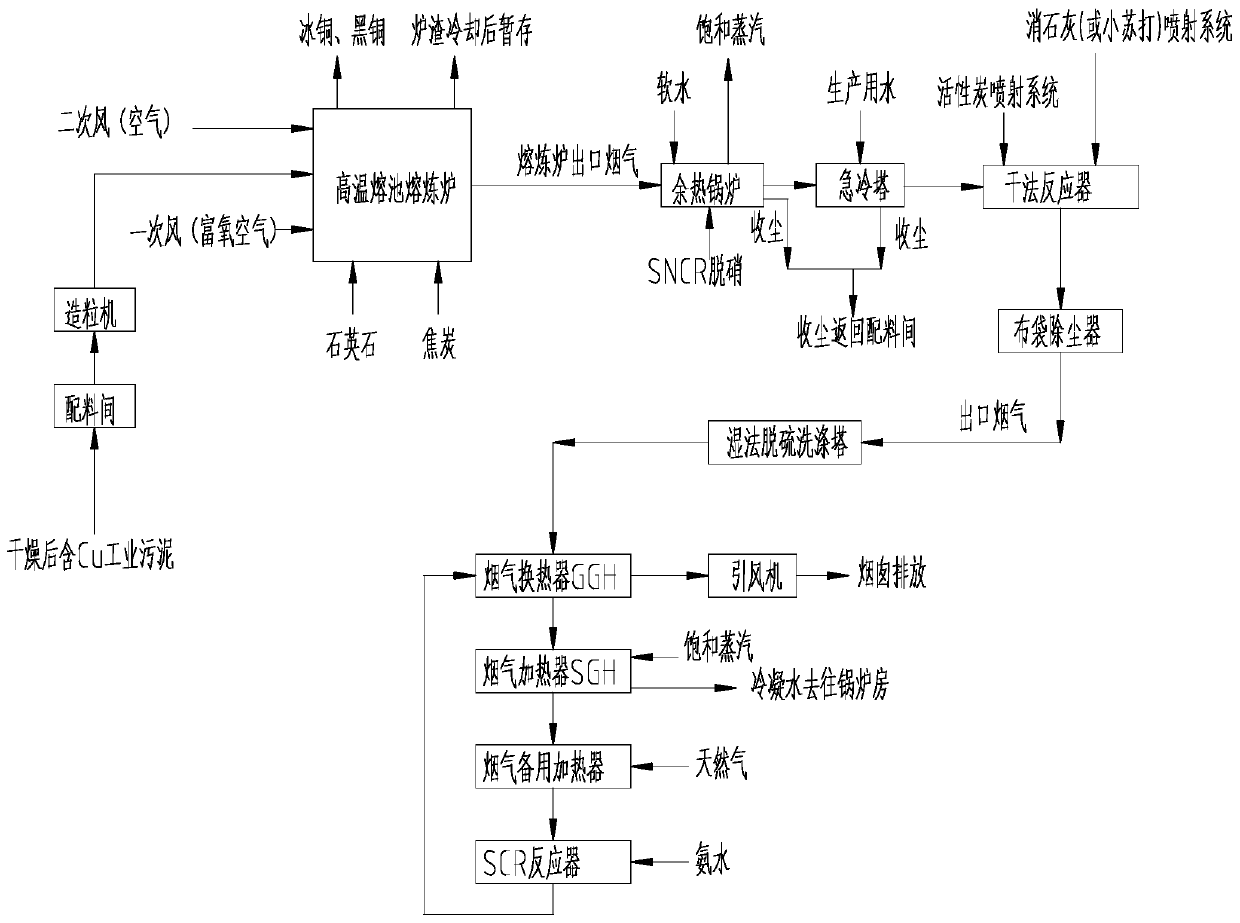

Cu-containing industrial sludge hazardous waste resourceful treatment system and treatment method thereof

InactiveCN111333290AHigh degree of automationGuaranteed uptimeGas treatmentSludge treatmentSludgeDust control

The invention relates to a Cu-containing industrial sludge hazardous waste resourceful treatment system. The Cu-containing industrial sludge hazardous waste resourceful treatment system comprises a batching room, a granulator, a smelting furnace, a waste heat boiler and a flue gas treatment system. The invention relates to a Cu-containing industrial sludge hazardous waste resourceful treatment method, which comprises the following steps of: sequentially carrying out batching, granulation and sludge pyrometallurgy to obtain matte and black copper; cooling flue gas by the waste heat boiler, conducting SNCR denitration, quenching, dry deacidification, cloth bag dust removal, wet deacidification and SCR reactor desulfurization treatment, and then performing discharging. According to the invention, the Cu component in the sludge is recovered to the maximum extent through a reasonable ratio of the components entering the furnace, and the flue gas produced by a high temperature molten pool ispurified through the reference of a mature purification process of hazardous waste incineration flue gas and reasonable process optimization so as to meet the emission standard requirement and achieve up-to-standard emission.

Owner:SHANGHAI INST FOR DESIGN & RES ON ENVIRONMENTAL ENG

Flue gas treatment system and method for cement kiln

PendingCN111111404AReduce the temperaturePromote decompositionGas treatmentDispersed particle separationThermodynamicsFlue gas

The invention relates to the technical field of flue gas treatment, and discloses a flue gas treatment system and method for a cement kiln; the flue gas treatment system comprises a flue gas extraction device, an air cooling device, a nitrogen reduction device, a desulfurization device and an induced draft device; the gas inlet end of the flue gas extraction device is used for being communicated with the cement kiln; the air cooling device is communicated with the flue gas extraction device and is used for carrying out shock cooling treatment on flue gas extracted by the flue gas extraction device; the gas outlet end of the flue gas extraction device is sequentially communicated with the nitrogen reduction device and the desulfurization device through a flue or sequentially communicated with the desulfurization device and the nitrogen reduction device through a flue, and the induced draft device is mounted on the flue; during flue gas treatment of the cement kiln, chlorine removal, alkali removal, desulfurization, denitrification and dioxin removal can be considered at the same time, the flue gas treatment efficiency is high, normal operation of the cement kiln is guaranteed, and ultra-clean emission of flue gas is achieved.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

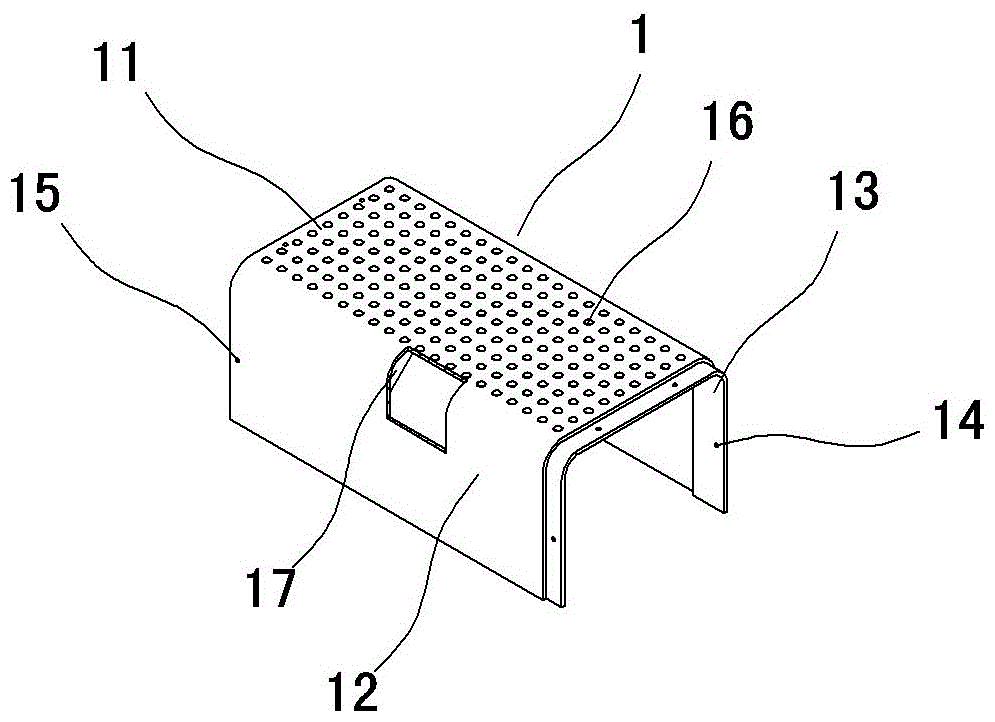

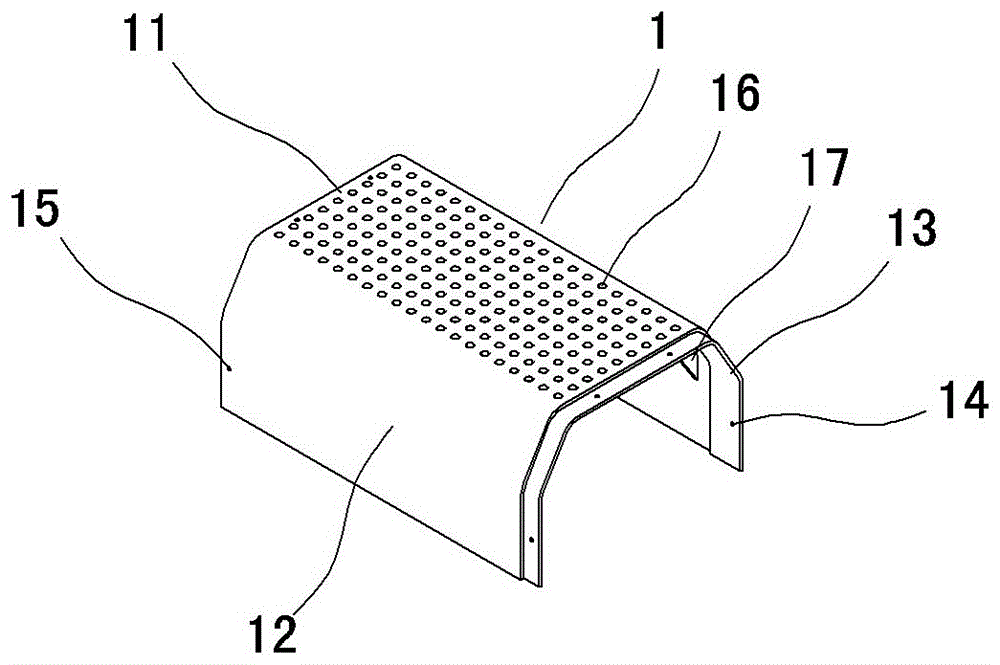

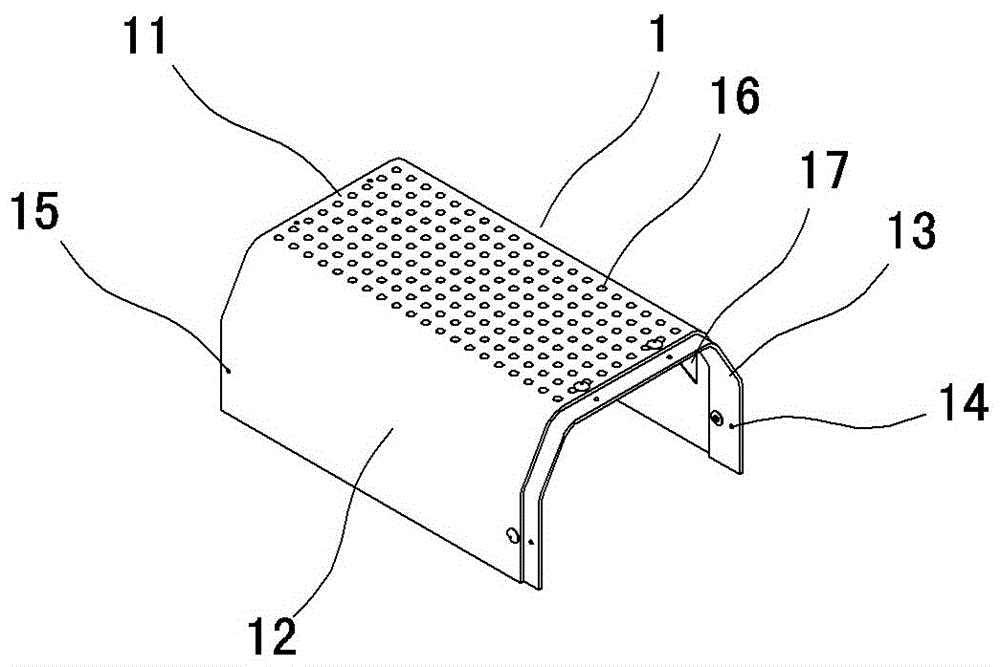

Earth ridge protecting cover or earth-free ridge for paddy fields and upland fields

The invention relates to an earth ridge protecting cover or earth-free ridge for paddy fields and upland fields. The earth ridge protecting cover or earth-free ridge comprises an earth ridge protecting cover or ridge body (1) of a reverse groove shape, the surfaces, facing the outer side, of two side plates (12) are smooth surfaces, overlap edges (13) are arranged on the edge of one end of the earth ridge protecting cover or ridge body (1) and are provided with first connecting holes (14), and second connecting holes (15) are formed in the other end of the earth ridge protecting cover or ridge body (1). When the earth ridge protecting cover or earth-free ridge is used as the earth ridge protecting cover, earth ridges of the paddy fields and the upland fields are protected against damage, and people do not need to repair the damaged or collapsed earth ridges with a lot of time, manpower and financial resources every year; when the earth ridge protecting cover or earth-free ridge is used as the earth-free ridge, the manpower and the cost for constructing the earth ridges can be saved, the land can be saved, the economical performance is high in the use process, weeds are prevented from growing on the earth-free ridge, grass seeds are avoided, and weed control in the fields is convenient.

Owner:MULING WUYUE ELECTRIC ENERGY STORAGE PROD TECH RES INST

Photocuring skin wound adhesive

InactiveCN113521375APrevent respawnIncrease motivationSurgical adhesivesBandagesGas phasePolymethyl methacrylate

The invention aims to provide a photocuring skin wound adhesive. The photocuring skin wound adhesive is prepared from the following raw materials: n-butyl alpha-cyanoacrylate, fumed silica, polymethyl methacrylate, a stabilizer, a photoinitiator and an accelerant. Compared with the prior art, the skin can be tightly attached to the product, wound infection can be effectively prevented, wound healing is accelerated, and the wound can be immediately soaked in water, bathed, subjected to field work and the like after being glued and cured, so that the wound can be effectively protected.

Owner:东莞市瞬力新材料科技有限公司

Negative electrode material, battery and vehicle

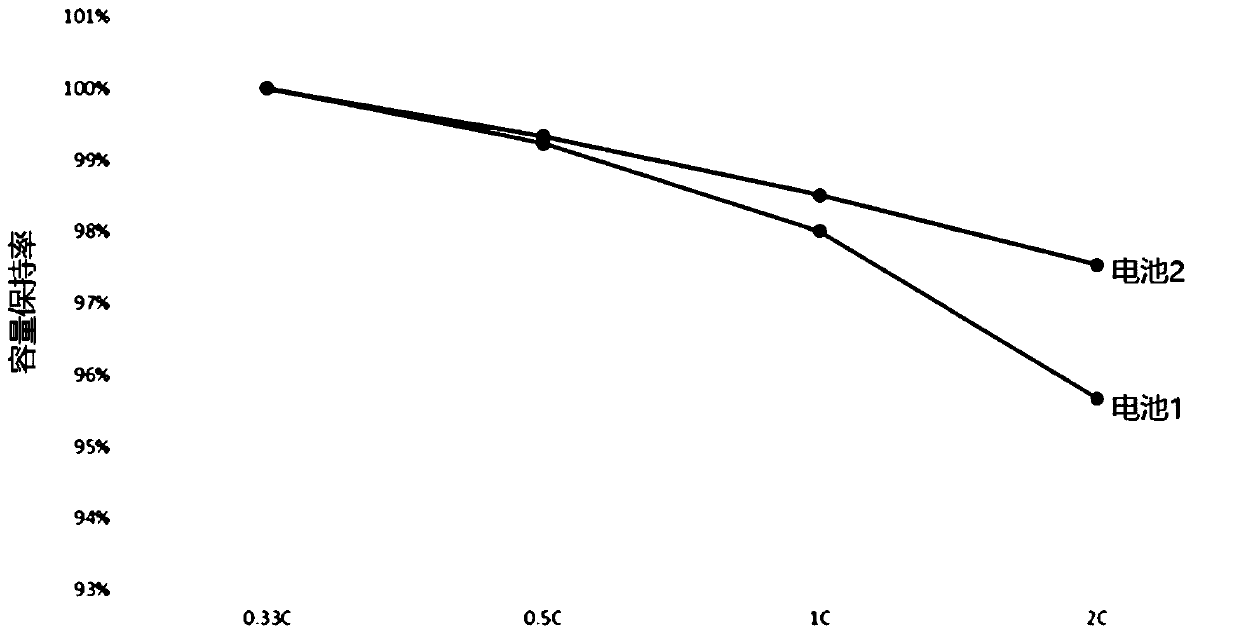

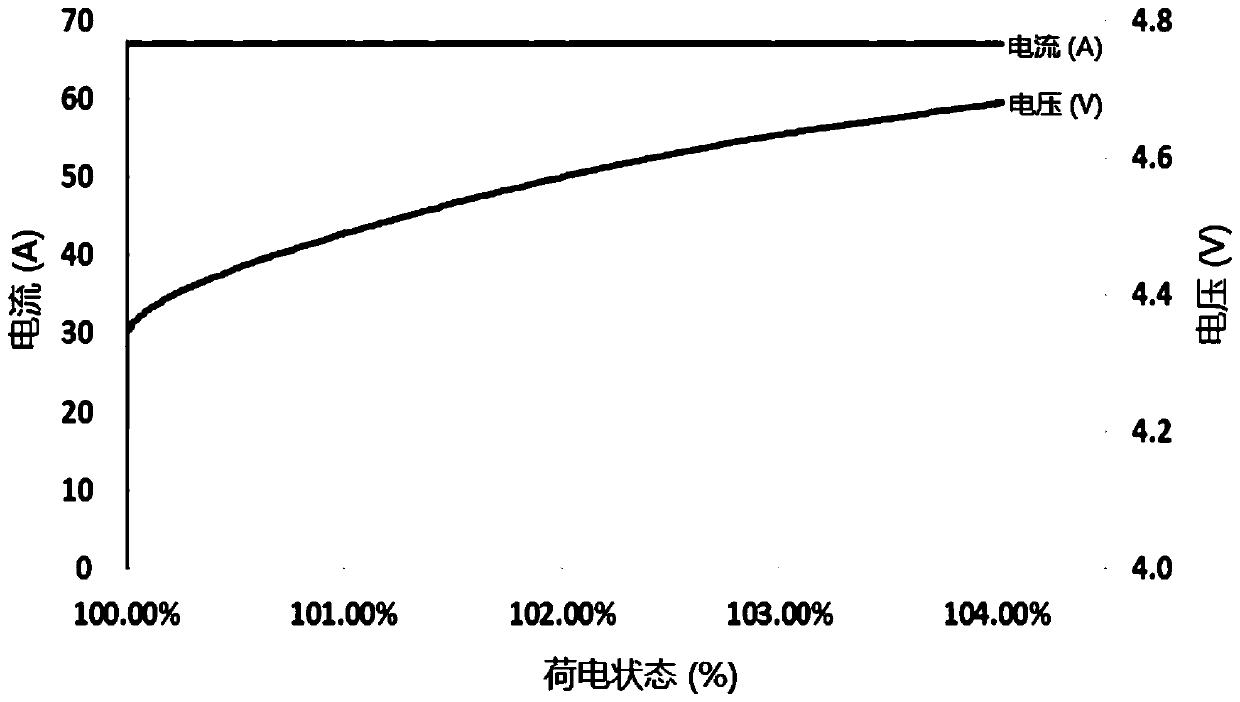

InactiveCN111430686AIncrease energy densityAvoid negative effectsSecondary cellsNegative electrodesBattery cellMaterials science

The invention discloses a negative electrode material, a battery and a vehicle. The negative electrode material comprises a first negative electrode active material, a second negative electrode activematerial, a third negative electrode active material, a first negative electrode conductive agent, a second negative electrode conductive agent, a third negative electrode conductive agent, a first negative electrode binder, a second negative electrode binder and a third negative electrode binder, wherein the first negative electrode active substance is a silicon-based negative electrode material, and the content of the first negative electrode active substance is 10-30% of the total mass of the negative electrode material. According to the negative electrode material, the active substance with high silicon content is adopted, so that the energy density can reach 320 W.h / kg or above, and meanwhile, through the optimization of other negative electrode material components, the performance,such as longer cycle life, etc., can be obtained.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Rural garbage harmless, reduction and recycling incinerator and method

PendingCN108224429ABurn fullyIncrease temperatureIndirect carbon-dioxide mitigationIncinerator apparatusAir preheaterCombustion

The invention discloses a rural garbage harmless, reduction and recycling incinerator and method. A smoke outlet in the top of a hearth is sequentially connected with an air preheater, a water coolingheat exchanger, a cyclone separator, a tail gas treatment device and a chimney through a pipeline, the incinerator further comprises a motor, a primary fan, a secondary air assembly and a nozzle array composed of multiple nozzles, the motor is used for driving the secondary air assembly and the primary fan to work, the nozzles are distributed in an inclined manner in the circumferential directionof the inner wall of a flue outlet in the top of the hearth, a spiral air flow is formed in a flue, and smoke is driven to be entrained and spirally ascend, the secondary air assembly sucks gas emitted by garbage from a material bin, meanwhile, negative pressure is formed in the material bin, and the gas is emitted to the flue outlet in the top of the hearth through a nozzle; the incinerator andmethod have the beneficial effects of being high in combustion efficiency, nearly zero in emission, low in running cost, wide in fuel application and the like, and are suitable for rural garbage harmless, reduction and recycling incinerating treatment of the China.

Owner:SOUTH CHINA UNIV OF TECH

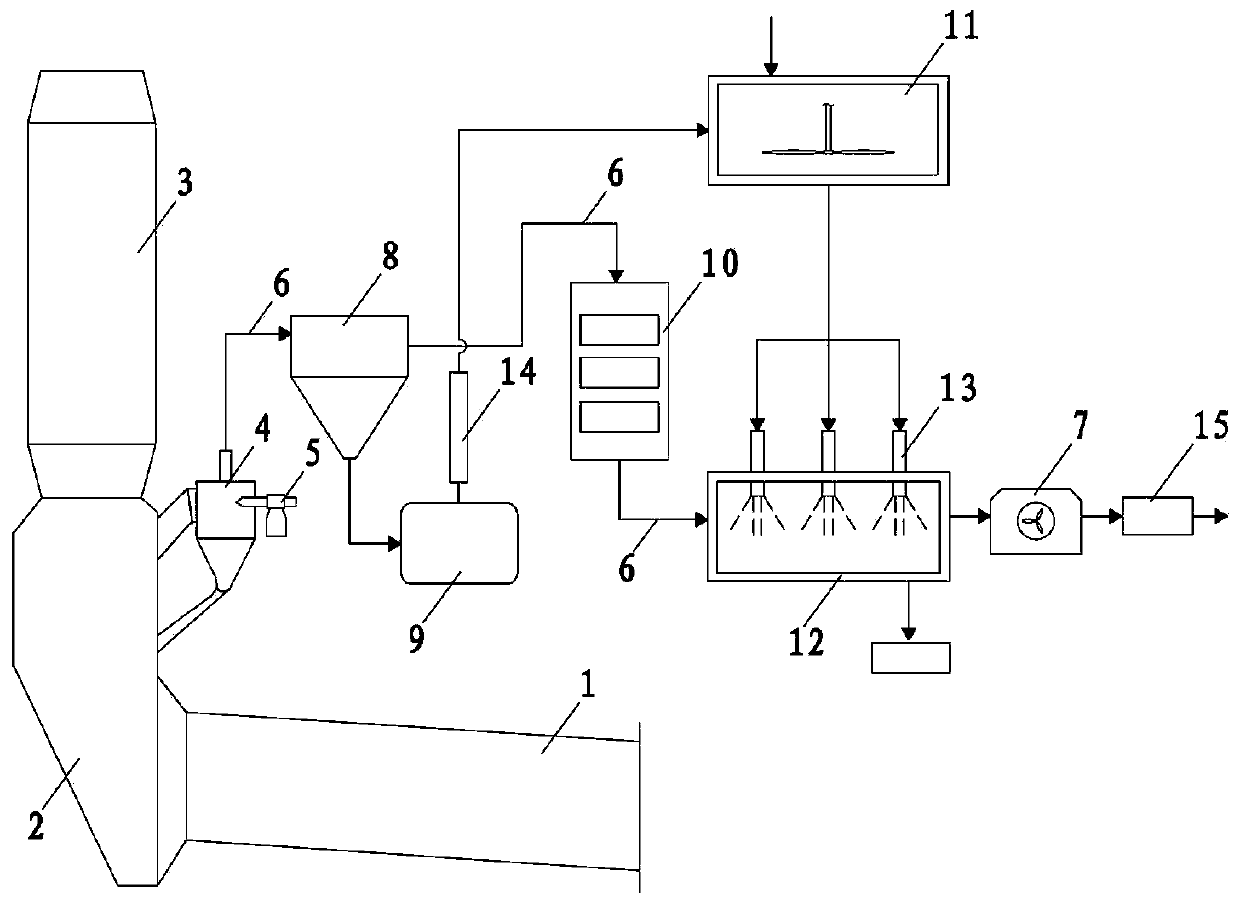

Arsenic collecting system for dioxin-containing smelting flue gas and method thereof

InactiveCN113731048APrevent respawnLower acid dew pointGas treatmentDispersed particle filtrationFlue gasNonferrous metal

The invention provides an arsenic collecting system for dioxin-containing smelting flue gas and a method thereof. The system comprises a first dust collection unit, a quenching deacidification unit, a sedimentation unit and a second dust collection unit. Through layer-by-layer cooperative utilization of the systems, the yield of arsenic trioxide is 95-98%, the yield of non-ferrous metal dust is greater than 98%, and the content of dioxin substances in finally discharged flue gas is below 0.5 ngTEQ / Nm<3>.

Owner:CHINA ENFI ENGINEERING CORPORATION

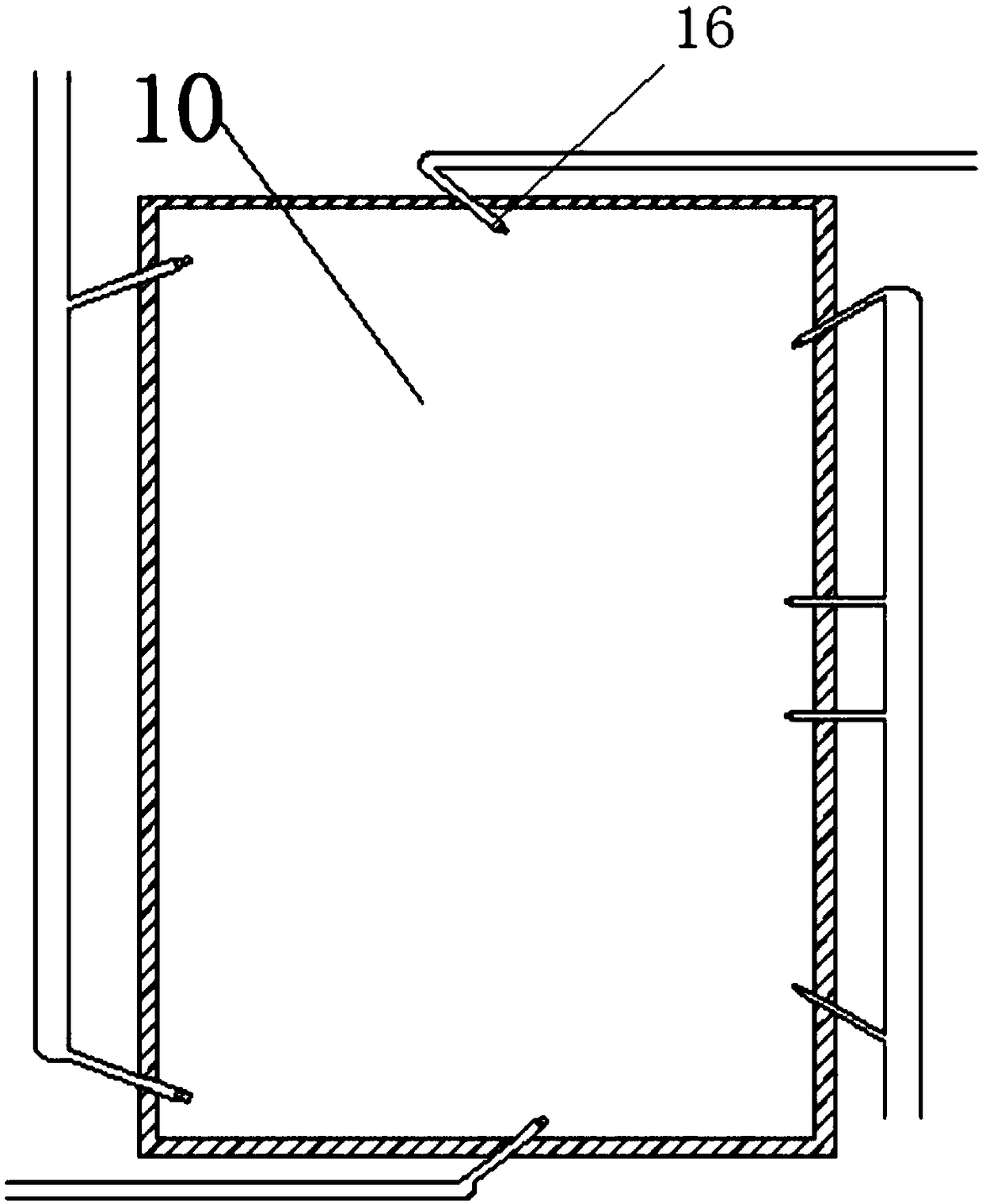

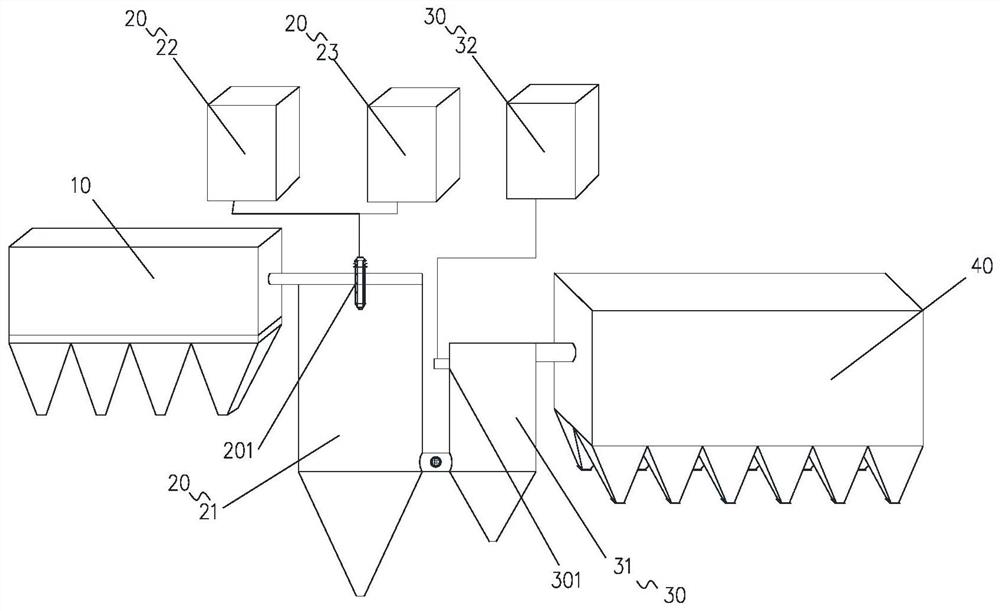

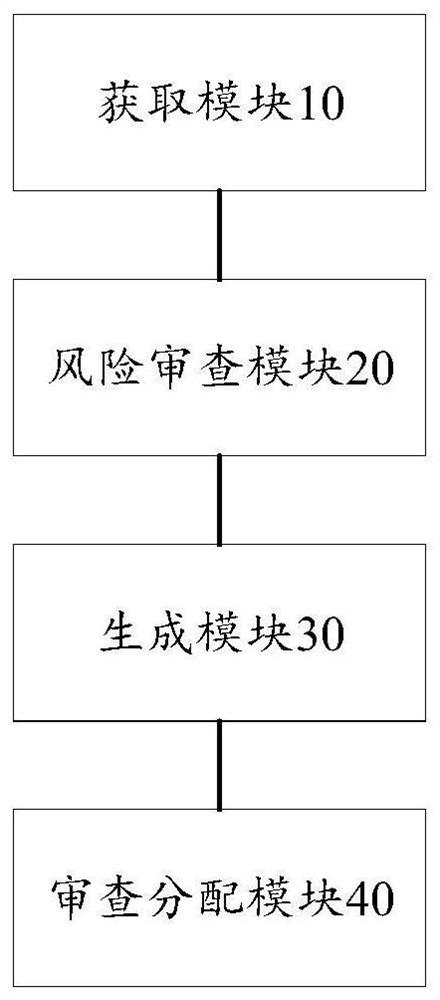

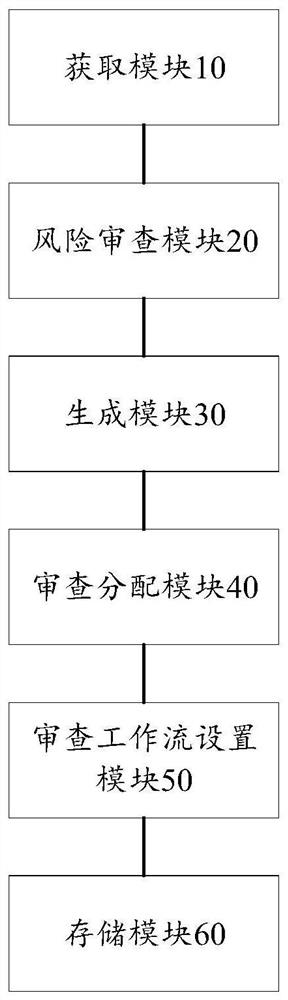

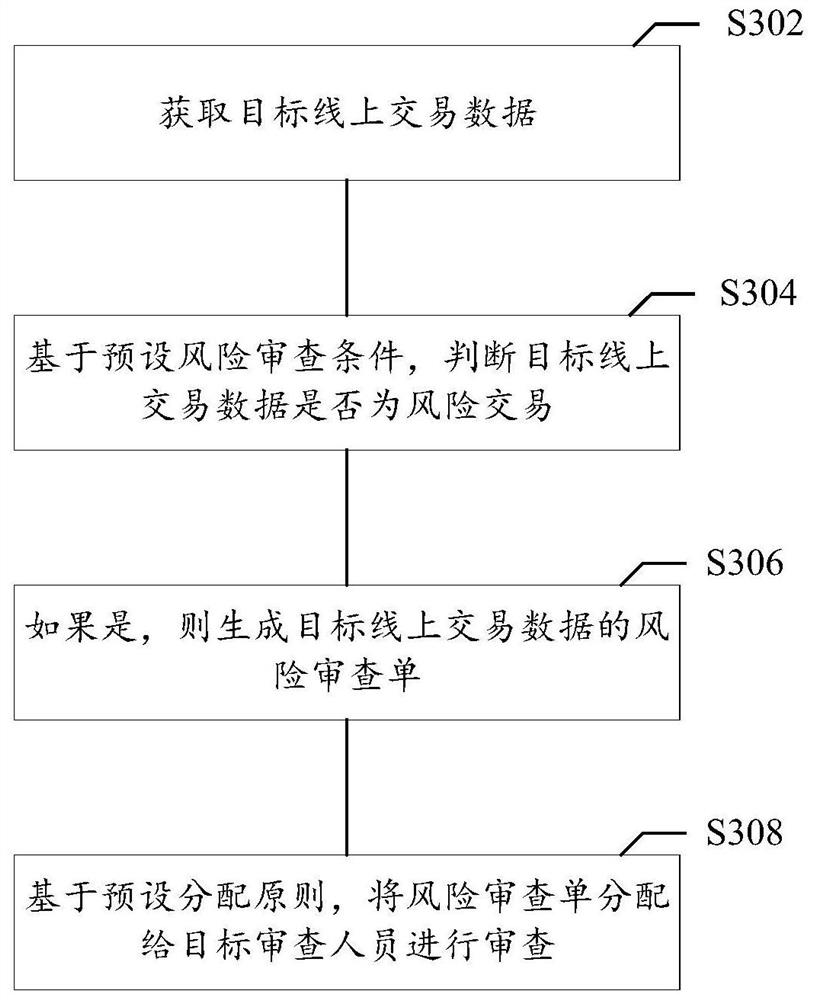

System and method for automatically generating risk review order and review mechanism

ActiveCN113256299AImprove judgment effectAvoid the risks of using a single process reviewFinanceProtocol authorisationRisk levelTransaction data

The invention provides a system and method for automatically generating a risk review order and a review mechanism, and the system comprises an obtaining module, a risk review module, a generation module, and a review distribution module; the obtaining module is used for obtaining target online transaction data; the risk review module is used for judging whether the target online transaction data is a risk transaction or not based on a preset risk review condition; the preset risk review condition comprises a business channel, a risk level of a current transaction and a request business attribute; the generation module is used for generating a risk review list of the target online transaction data if the target online transaction data is judged to be the risk transaction; and the review distribution module is used for distributing the risk review sheet to a target review person for review based on a preset distribution principle. According to the embodiment of the invention, the technical problems of high cost, poor timeliness and inflexibility in a manual auditing process in the prior art are relieved.

Owner:杭州顶象科技有限公司

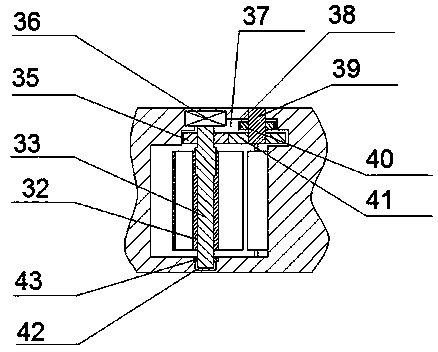

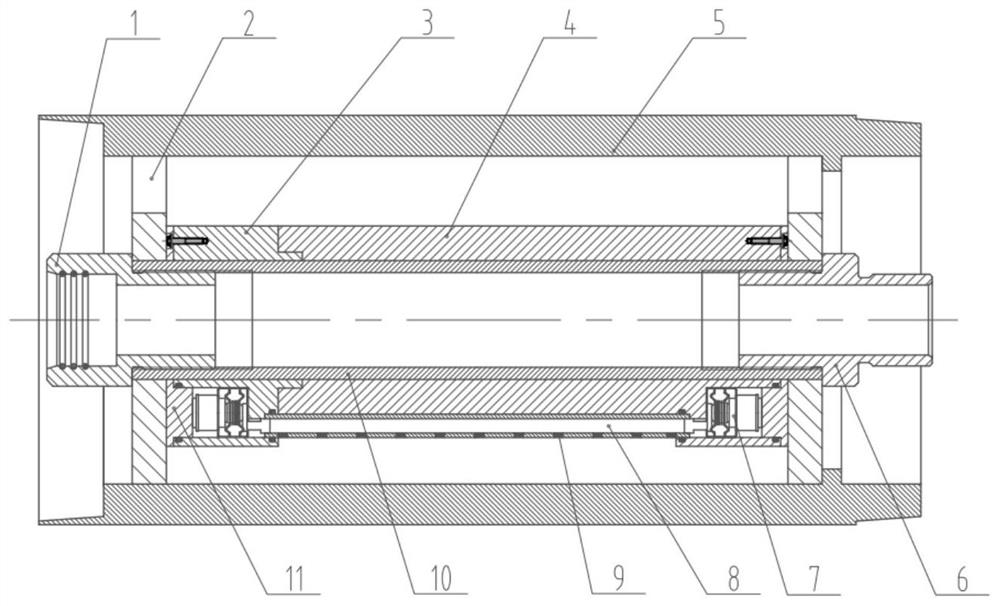

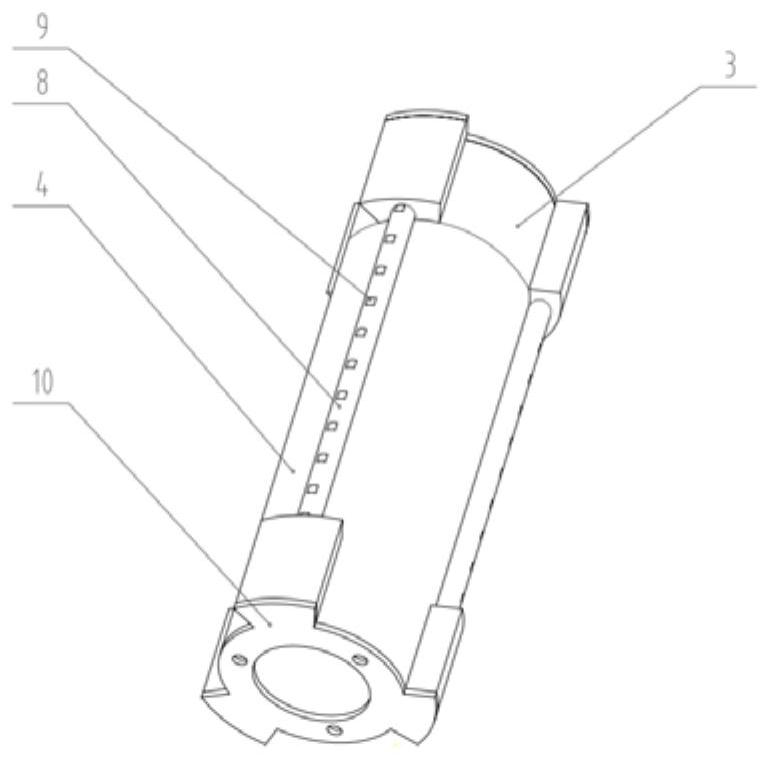

Double-layer pipe microwave heating short joint for hydrate transportation

ActiveCN111810060APrevent respawnPromote decompositionDrilling rodsInsulationDouble-walled pipeWaveguide

The invention discloses a double-layer pipe microwave heating short joint for hydrate transportation. The double-layer pipe microwave heating short joint for hydrate transportation comprises a microwave heating device, an inner pipe, an outer pipe, a supporting plate, an upper inner pipe joint and a lower inner pipe joint. The microwave heating device consists of a shell, a shell joint, magnetrons, a waveguide tube and end covers, wherein the magnetrons are respectively packaged into the shell and the shell joint through the end covers, and the waveguide tube is connected with the corresponding magnetrons to be fixed on the outer wall of the shell. The microwave heating device is fixed on the outer wall of the inner pipe through the supporting plate, the upper inner pipe joint and the lower inner pipe joint, and is positioned by utilizing steps on the inner wall of the outer pipe. According to the double-layer pipe microwave heating short joint for hydrate transportation, in the process of exploiting and pumping hydrate by using a double-layer pipe, the hydrate in a conveying pipe can be effectively prevented from being generated again, the exploitation efficiency is improved, andthe safety of equipment is guaranteed.

Owner:SOUTHWEST PETROLEUM UNIV +1

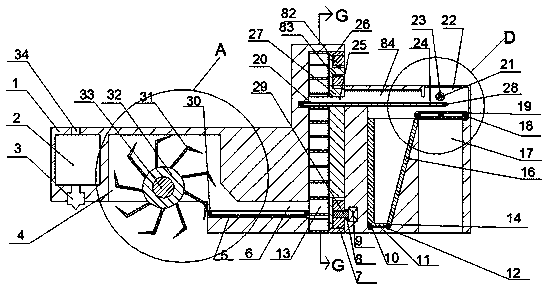

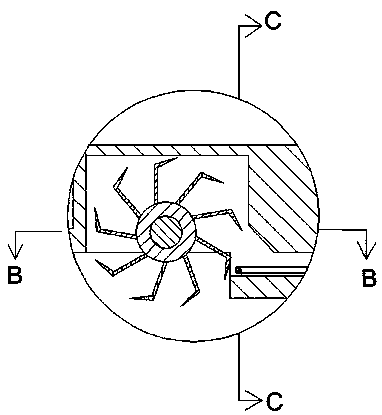

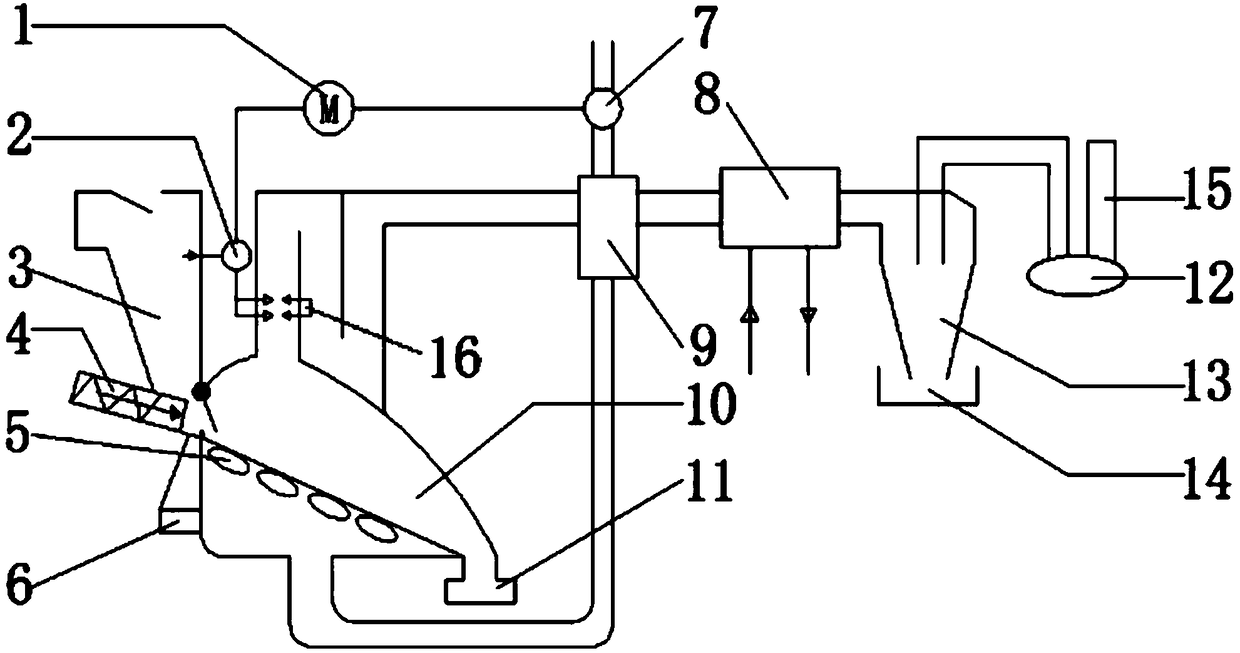

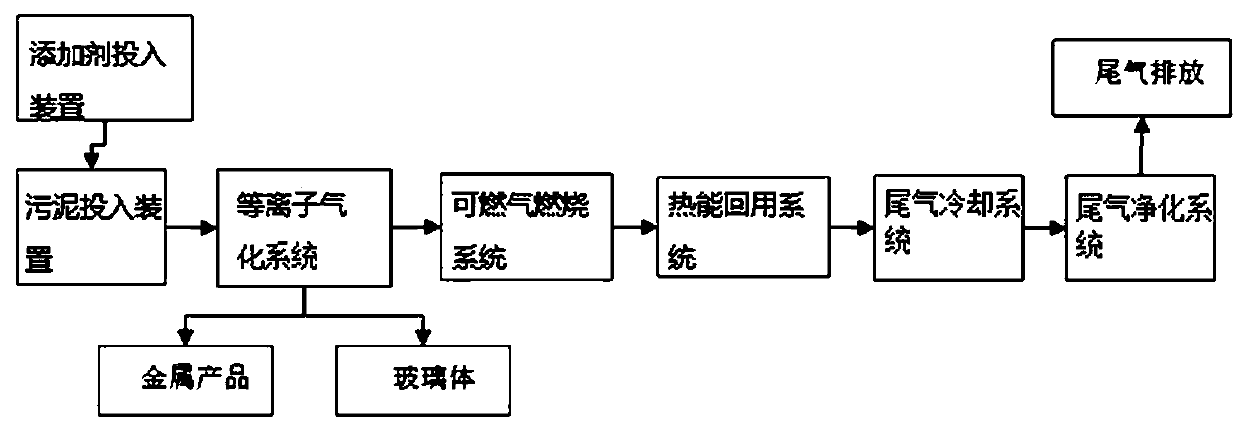

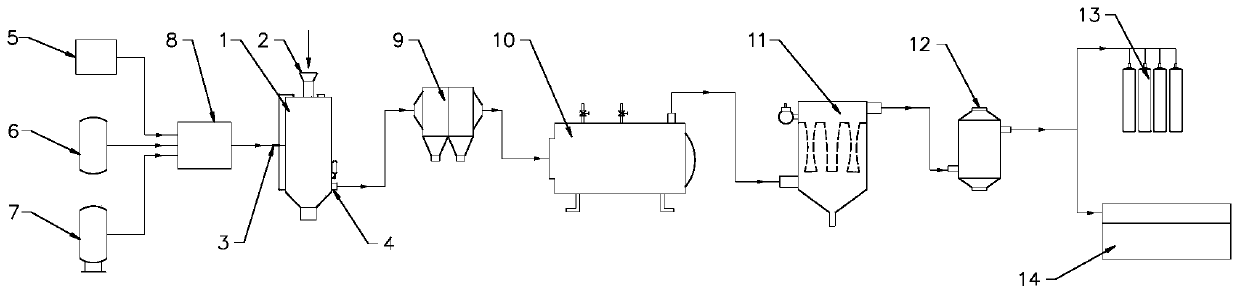

Process system and method for plasma gasification of industrial sludge

PendingCN108676572AAvoid harmPrevent respawnSludge treatmentSpecial form destructive distillationProcess systemsCombustion system

The invention discloses a process system and a method for plasma gasification of industrial sludge and belongs to the technical field of harmless disposal of industrial sludge. The process system comprises a sludge adding device, a plasma gasification system, a combustible gas combustion system and a tail gas treatment system which are sequentially connected; an additive adding device is connectedwith the sludge adding device; the plasma gasification system comprises a plasma gasifier; the combustible gas combustion system comprises a combustion tower with an oxygen supply pipeline; the tailgas treatment system comprises a tail gas cooling system and a tail gas purifying system.

Owner:CHENGDU YUANYONG TECH DEV

Soil turning device with tilling depth adjusting structure for agricultural implement and soil turning method thereof

The invention discloses a soil turning device with a tilling depth adjusting structure for an agricultural implement and a soil turning method thereof. The soil turning device comprises an agricultural machine body. The device is characterized in that: a tilling depth adjusting mechanism capable of performing tilling depth on land and digging holes at equal intervals to facilitate vegetable planting is arranged in the left side of the agricultural machine body, equally-divided gears are welded to the front outer side and the rear outer side of an upper rotating shaft, a torsion spring rod is welded to the inner side of the first transmission gear, air cylinders are welded to the left side of the front portion and the left side of the rear portion of the agricultural machine body correspondingly, a weed collecting mechanism capable of collecting dug weeds is arranged below a soil turning mechanism, and a weed taking mechanism capable of taking out the weeds collected above the weed collecting mechanism is installed above a mincing mechanism. The tilling depth adjusting mechanism can be used for intermittently digging holes in the soil turning process through a soil turning assembly, so that the situation that holes need to be manually dug in the soil one by one through a hoe in the later period is avoided, the efficiency of the agricultural machine body is improved, the manual labor force is reduced, and the overall practicability is improved.

Owner:惠州市盛世机械科技有限公司

Acne removal essential oil and preparation process thereof

InactiveCN107898750APrevent respawnImprove healthCosmetic preparationsToilet preparationsLavender oilMedicine

The invention discloses acne removal essential oil. According to the formula, the acne removal essential oil contains the following raw materials in parts by weight: 45-65 parts of a juniper extract,45-65 parts of lavender oil, 25-30 parts of nursing oil, 25-30 parts of melaleuca alternifolia leaf oil, 25-30 parts of an aloe extracting solution, 1-4 parts of a honeysuckle extract and 1-4 parts ofa honey extract. The invention further provides a preparation process of the acne removal essential oil. According to the acne removal essential oil, bacteria in acnes can be killed, and meanwhile, the re-growth of the bacteria can be prevented during the removal; and the melaleuca alternifolia leaf oil is capable of purifying bacteria processed by the juniper extract, refreshing brain and restoring vitality; and the health level of the body can be increased while the skin is improved, and the acne removal essential oil can meet the requirements of modern people.

Owner:湖北瑞晟生物有限责任公司

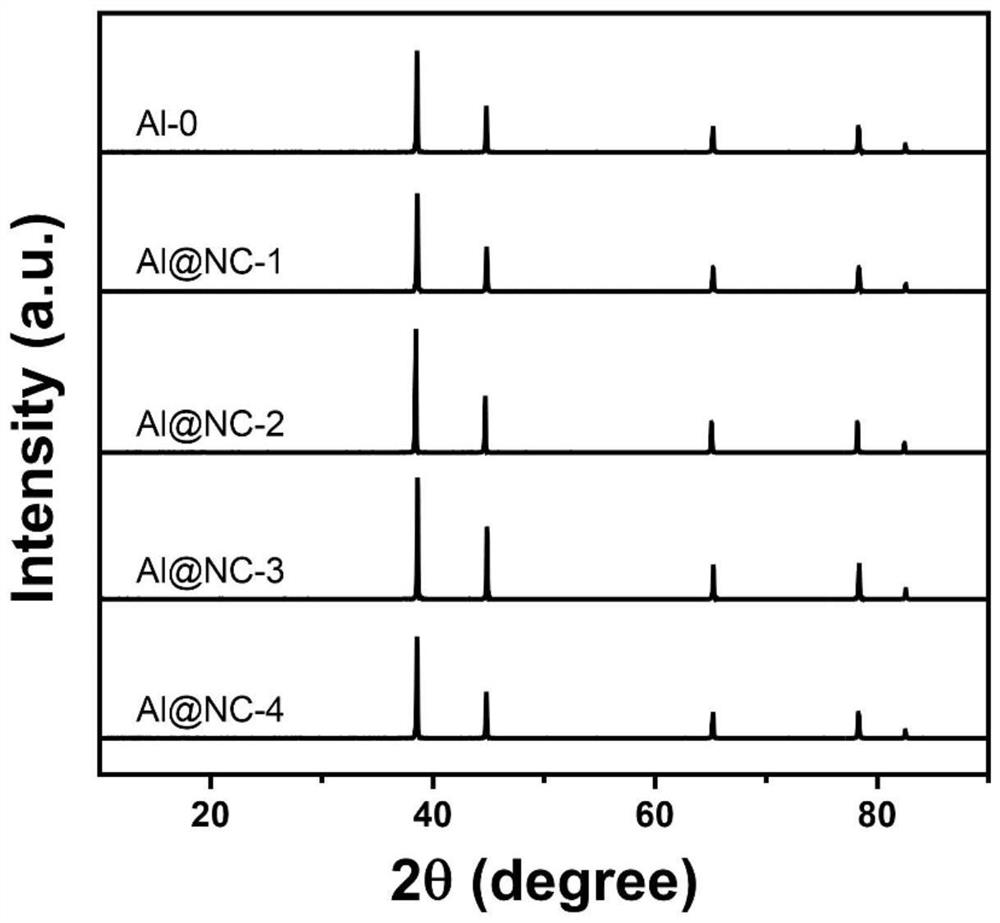

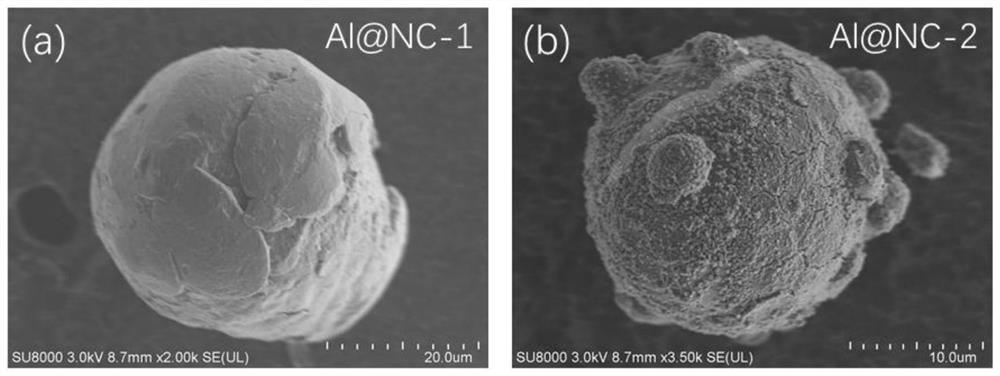

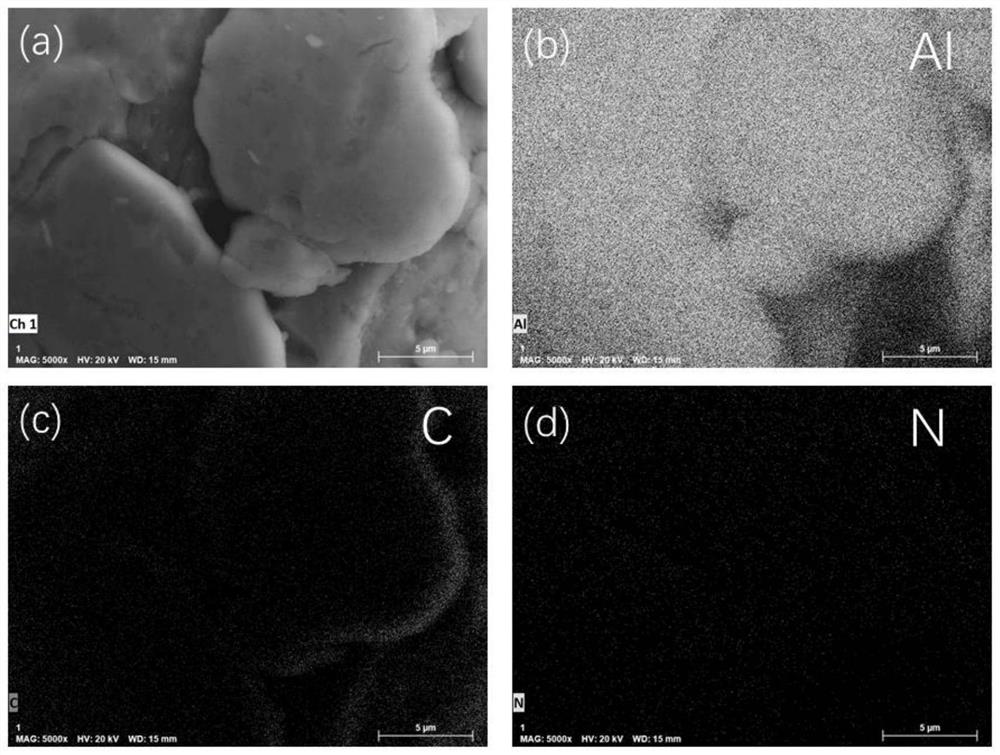

Nitrogen-doped carbon-coated aluminum material as well as preparation method and application thereof

ActiveCN114669741AInhibit surface passivationPrevent respawnTransportation and packagingMetal-working apparatusEnvironmental chemistryCarbon source

The invention belongs to the technical field of water and wastewater treatment, and particularly relates to a nitrogen-doped carbon-coated aluminum material, a preparation method thereof and application of the nitrogen-doped carbon-coated aluminum material to removal of oxysalt and halogenated organic pollutants. The invention provides a preparation method of a nitrogen-doped carbon-coated aluminum material. According to the preparation method, dopamine is used as a carbon source and a nitrogen source, nitrogen elements are introduced into a formed carbon layer by utilizing amino groups contained in the dopamine, and then the nitrogen-doped carbon-coated aluminum material is prepared in a manner of calcination in a nitrogen atmosphere. According to the method, the nitrogen-doped carbon layer is formed on the aluminum surface, the reduction activity of aluminum is improved, an oxidation film on the aluminum surface is prevented from being formed, meanwhile, the nitrogen-doped carbon layer can accelerate electrons to be transmitted outwards from an aluminum inner core, and therefore the activity of aluminum for reducing and degrading pollutants is improved. The nitrogen-doped carbon-coated aluminum material disclosed by the invention can be used for efficiently reducing and degrading oxysalt and halogenated organic pollutants in water, wastewater and strong brine.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Multi-oxygen three-section type waste incineration and flue gas comprehensive utilization device and using method thereof

InactiveCN110186054AShorten cooling dwell timePrevent respawnCombustion technology mitigationIncinerator apparatusActivated carbonAutomatic control

The invention relates to a multi-oxygen three-section type waste incineration and flue gas comprehensive utilization device and an using method thereof. The multi-oxygen three-section type waste incineration and flue gas comprehensive utilization device comprises an incinerator system, an oxygen supply system, a flue gas treatment system, an automatic ignition system and an automatic control system; the incinerator system comprises an incinerator, wherein a garbage feeding port, an oxygen inlet and a high-temperature flue gas outlet are formed in the incinerator; the flue gas treatment systemcomprises a high-temperature dust remover, a waste heat recoverer, a bag-type dust remover and an activated carbon adsorption purifier; the high-temperature dust remover is connected to the high-temperature flue gas outlet through a flue gas pipeline, the waste heat recoverer is connected with the high-temperature dust remover, the bag-type dust remover is connected to the waste heat recoverer, and the activated carbon adsorption purifier is connected to the bag-type dust remover. The device has the advantages of being reasonable in structural design, convenient to operate and use, low in maintenance cost, relatively high in automation degree and capable of effectively improving the harmless treatment of the household garbage, and can effectively protecting the environment and the like byincinerating the household garbage and carrying out harmless and full utilization of the flue gas.

Owner:王立臣 +1

Quick-acting emulsifiable concentrate for burns and scalds

InactiveCN111012843APromote recoveryEliminate burning painHydroxy compound active ingredientsPharmaceutical delivery mechanismCalcium hydroxideSide effect

The invention relates to quick-acting emulsifiable concentrate for burns and scalds, wherein the quick-acting emulsifiable concentrate is prepared by mixing 30-50 g of tea oil, 5-10 g of borneol, 5-10g of milk, 20-30 g of egg white and 1000-2000 g of a calcium hydroxide saturated solution. According to the invention, the pure natural quick-acting emulsifiable concentrate used for burns and scaldsand having no toxic and side effect is provided, and can be directly applied to burns and scalds, wherein the wound surface is not disinfected before the coating; and after the quick-acting emulsifiable concentrate for burns and scalds is used, burning pain can be immediately eliminated, then the red and swollen phenomenon is gradually eliminated, the growth recovery capacity is improved, wound recovery is fast, the healing period is short, the remarkable treatment effect on burns and scalds is achieved, the mild burn and scald healing period is 1-5 days, the moderate burn and scald healing period is 7-12 days and no scar is left, the severe burn and scald healing period is about 30 days and no scar is left in 80% of the severe burn and scald.

Owner:湘潭博奥生态科技有限公司

A kind of industrial sludge resource treatment method

ActiveCN108840544BAvoid emissionsAvoid build temperatureSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeProcess engineering

The invention discloses an industrial sludge resource treatment method, which belongs to the technical field of harmless disposal of industrial sludge, and comprises a sludge sorting and mixing step, a sludge transporting step, a hydrothermal reaction step, a plate and frame filter press dehydration step, Sludge drying steps, cracking steps, plasma gasification steps and tail gas treatment steps are a method that can effectively utilize the calorific value of sludge, recover the potential heat energy in it, recover the metal part, melt the remaining inorganic substances into glass, and convert the remaining Heavy metals are wrapped in it and can be used as building materials, avoiding the harm of heavy metals entering the water body, and basically achieving zero discharge of pollutants. Industrial sludge resource treatment method.

Owner:CHENGDU YUANYONG TECH DEV

Quenching absorption tower used for treating waste gas generated by recycling of hazardous waste inorganic salts

ActiveCN110756006ANeutralize acidic ingredientsPrevent respawnGas treatmentDispersed particle separationInorganic saltsCalcium hydroxide

The invention relates to the field of environmental protection management, in particular to a quenching absorption tower used for treating waste gas generated by recycling of hazardous waste inorganicsalts. The quenching absorption tower is characterized by comprising main parts of a quenching tower body, a quenching liquid spraying gun and a flue gas outlet-inlet. According to the quenching absorption tower, the mode that a calcium hydroxide emulsion is sprayed for direct cooling is adopted, thus flue gas flowing through the interior of the tower can make direct contact with sprayed-in liquid after atomization, the mass transfer speed and the heat transfer speed are quite high, the sprayed-in liquid is quickly vaporized to take away a large amount of heat, the temperature of the flue gasis quickly decreased to reach about 200 DEG C, and thus re-generation of dioxin substances is avoided; meanwhile, acidic components in the flue gas can be neutralized; and meanwhile, an anti-corrosion and high-temperature-resistant refractory material is adopted as the face, making contact with the flue gas, in the quenching tower body, wall sticking of alkali liquor and corrosion of equipment can be prevented, and the service life of the equipment is prolonged.

Owner:内蒙古中泰汇金环保科技有限公司

Method for producing low-sulfur gasoline

ActiveCN102443433BPrevent respawnAvoid Hydrogenation LossTreatment with hydrotreatment processesCounter flowGas phase

The invention relates to a method for producing low-sulfur gasoline, which comprises the following steps that: firstly, gasoline raw materials are fractionated into light and heavy gasoline fractions, the light gasoline fractions are subjected to alkali washing for removing sulfur and alcohol, the heavy gasoline fractions are subjected to catalytic hydrogenation for removing sulfur-containing compounds, the heavy gasoline fractions after the hydrogenation desulfuration are introduced into a counter flow reactor from the middle part, hydrogenation sulfur and alcohol removal catalysts are filled in positions under a material inlet of the counter flow reactor, hydrogen-rich gas is introduced from the bottom of the reactor, a part of heavy gasoline fractions are vaporized into gas phase ingredients and liquid phase ingredients, the liquid phase ingredients flow from top to bottom and are in count flow contact with hydrogen gas on the catalysts for carrying out hydrogenation sulfur and alcohol removal reaction, the liquid phase ingredients after the sulfur and alcohol removal flow out from the bottom of the reactor, the gas phase ingredients and other gas are discharged out from the top of the reactor, the gas phase ingredients after the condensation are mixed with the liquid phase ingredients discharged from the bottom of the tower and the light gasoline fractions subjected to the alkali washing for removing sulfur and alcohol to obtain gasoline products. When the method provided by the invention is adopted, the gasoline product with the sulfur and alcohol sulfur content lower than 3mug / g can be producted, and simultaneously, the total sulfur content of the gasoline product is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com