Quenching absorption tower used for treating waste gas generated by recycling of hazardous waste inorganic salts

A quenching absorption tower and inorganic salt technology, which is applied in the field of quenching absorption towers, can solve the problems of acid-base liquid sticking to the wall, affecting environmental safety, complex sources, etc., and achieves the effect of avoiding regeneration and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

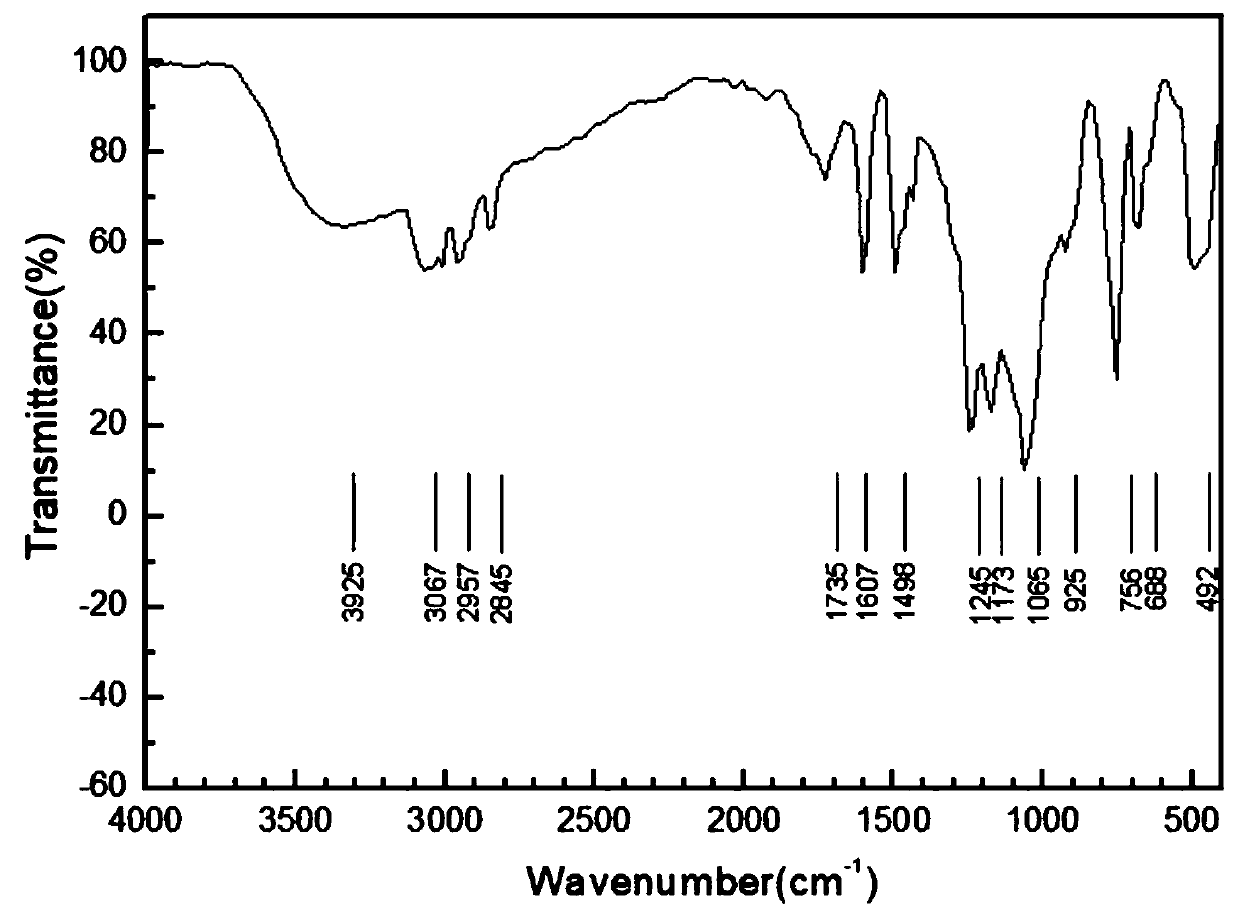

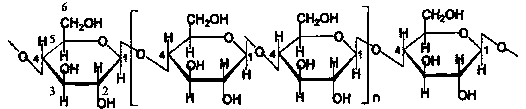

Image

Examples

Embodiment 1

[0029]A quenching absorption tower for treating waste gas produced by recycling hazardous waste inorganic salts, characterized in that the main components include a quenching tower body, a quenching liquid spray gun, and a flue gas inlet and outlet; the quenching tower body includes a cylindrical section and The conical section, the cylindrical section is arranged at the lower part, and the conical section is arranged at the upper part; the inside of the quench tower body adopts a double-layer structure, and the contact surface with the flue gas is a kind of anti-corrosion and high-temperature resistant refractory material; the quench liquid spray gun has The nozzle and the axis of the quench tower body form an angle of 20°, and the atomization of the absorbent slurry is completed by compressed air; the flue gas inlet is set at the bottom of the cylindrical section, and a temperature detector is installed to monitor the temperature of the flue gas inlet. The gas outlet is set o...

Embodiment 2

[0040] A quenching absorption tower for treating waste gas produced by recycling hazardous waste inorganic salts, characterized in that the main components include a quenching tower body, a quenching liquid spray gun, and a flue gas inlet and outlet; the quenching tower body includes a cylindrical section and The conical section, the cylindrical section is arranged at the lower part, and the conical section is arranged at the upper part; the inside of the quench tower body adopts a double-layer structure, and the contact surface with the flue gas is a kind of anti-corrosion and high-temperature resistant refractory material; the quench liquid spray gun has The nozzle and the axis of the quench tower body form an angle of 20°, and the atomization of the absorbent slurry is completed by compressed air; the flue gas inlet is set at the bottom of the cylindrical section, and a temperature detector is installed to monitor the temperature of the flue gas inlet. The gas outlet is set ...

Embodiment 3

[0051] A quenching absorption tower for treating waste gas produced by recycling hazardous waste inorganic salts, characterized in that the main components include a quenching tower body, a quenching liquid spray gun, and a flue gas inlet and outlet; the quenching tower body includes a cylindrical section and The conical section, the cylindrical section is arranged at the lower part, and the conical section is arranged at the upper part; the inside of the quench tower body adopts a double-layer structure, and the contact surface with the flue gas is a kind of anti-corrosion and high-temperature resistant refractory material; the quench liquid spray gun has The nozzle and the axis of the quench tower body form an angle of 20°, and the atomization of the absorbent slurry is completed by compressed air; the flue gas inlet is set at the bottom of the cylindrical section, and a temperature detector is installed to monitor the temperature of the flue gas inlet. The gas outlet is set ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com