Multi-oxygen three-section type waste incineration and flue gas comprehensive utilization device and using method thereof

A waste incineration, three-stage technology, which is applied to the multi-oxygen three-stage waste incineration and flue gas comprehensive utilization device and its application field, and can solve the problems of low temperature of waste incineration, non-harmful treatment of flue gas, and decomposition of dioxin Incomplete and other problems, to achieve the effect of improving utilization, shortening the cooling time, and preventing regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

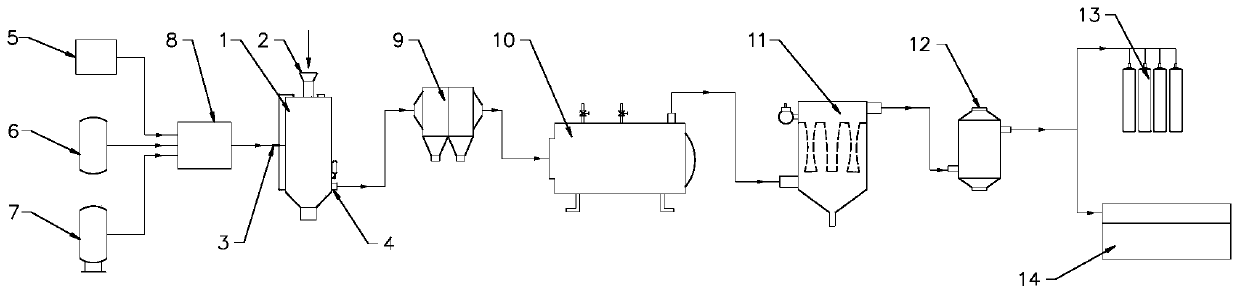

[0023] Attached below figure 1 The multi-oxygen three-stage garbage incineration and flue gas comprehensive utilization device of the present invention will be described in detail.

[0024] A multi-oxygen three-stage garbage incineration and flue gas comprehensive utilization device, the device includes an incinerator system, an oxygen supply system, a flue gas treatment system, an automatic ignition system and an automatic control system; wherein,

[0025] The incinerator system includes an incinerator 1, and the incinerator is provided with a garbage feed port 2, an oxygen inlet 3, and a high-temperature flue gas outlet 4; The slag breaker is arranged under the garbage feeding port for crushing the garbage; the multiple oxygen burners are arranged on the side wall of the furnace body of the incinerator and connected with the oxygen inlet; the incinerator There is also a slag discharge assembly at the bottom of the furnace body;

[0026] The oxygen supply system includes an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com