Method for producing low-sulfur gasoline

A gasoline and heavy gasoline technology, applied in the field of gasoline hydrodesulfurization, can solve the problems of reduced total sulfur in the product and cannot be removed, and achieve the effect of low octane loss and avoid hydrogenation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

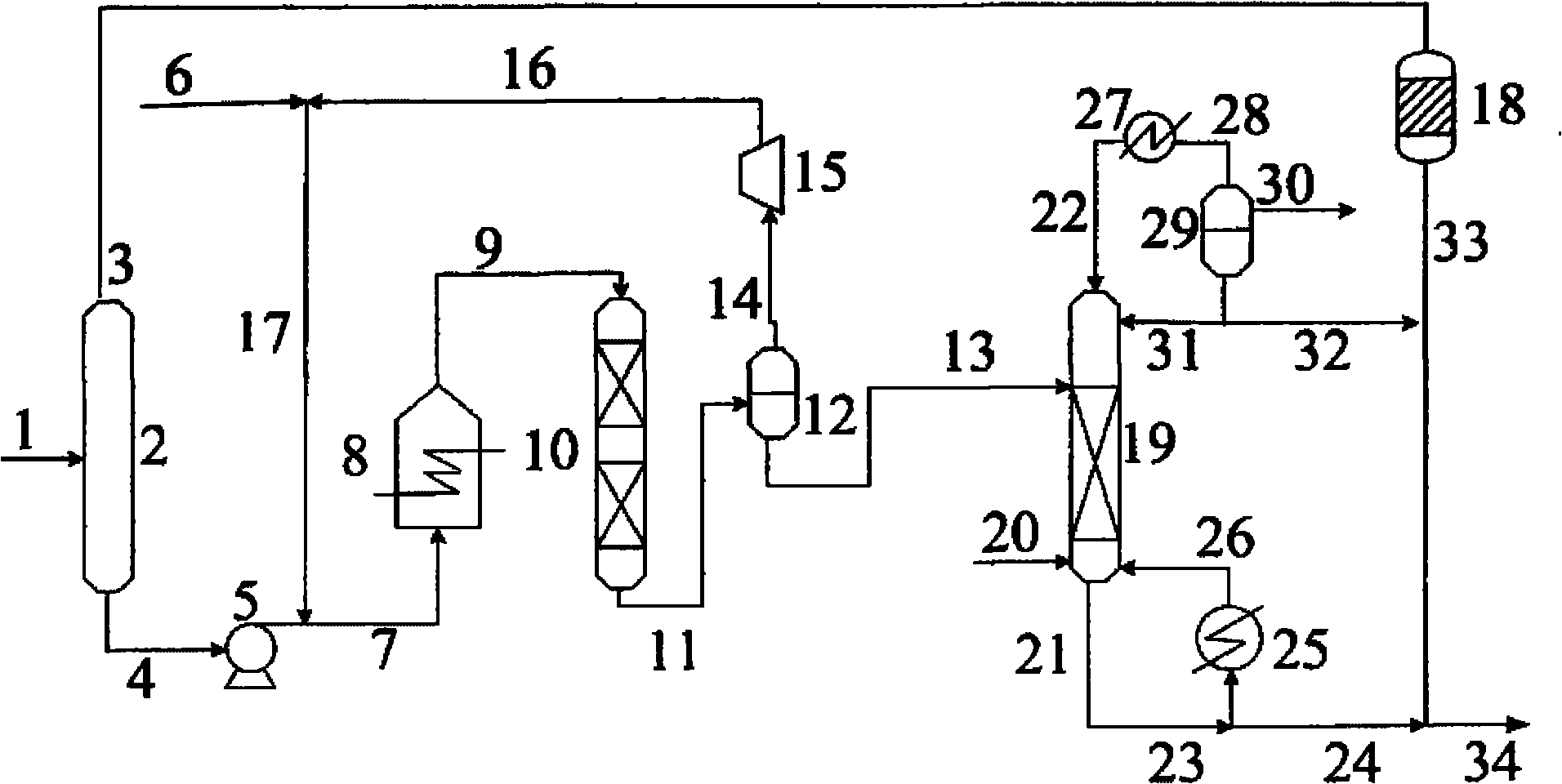

Method used

Image

Examples

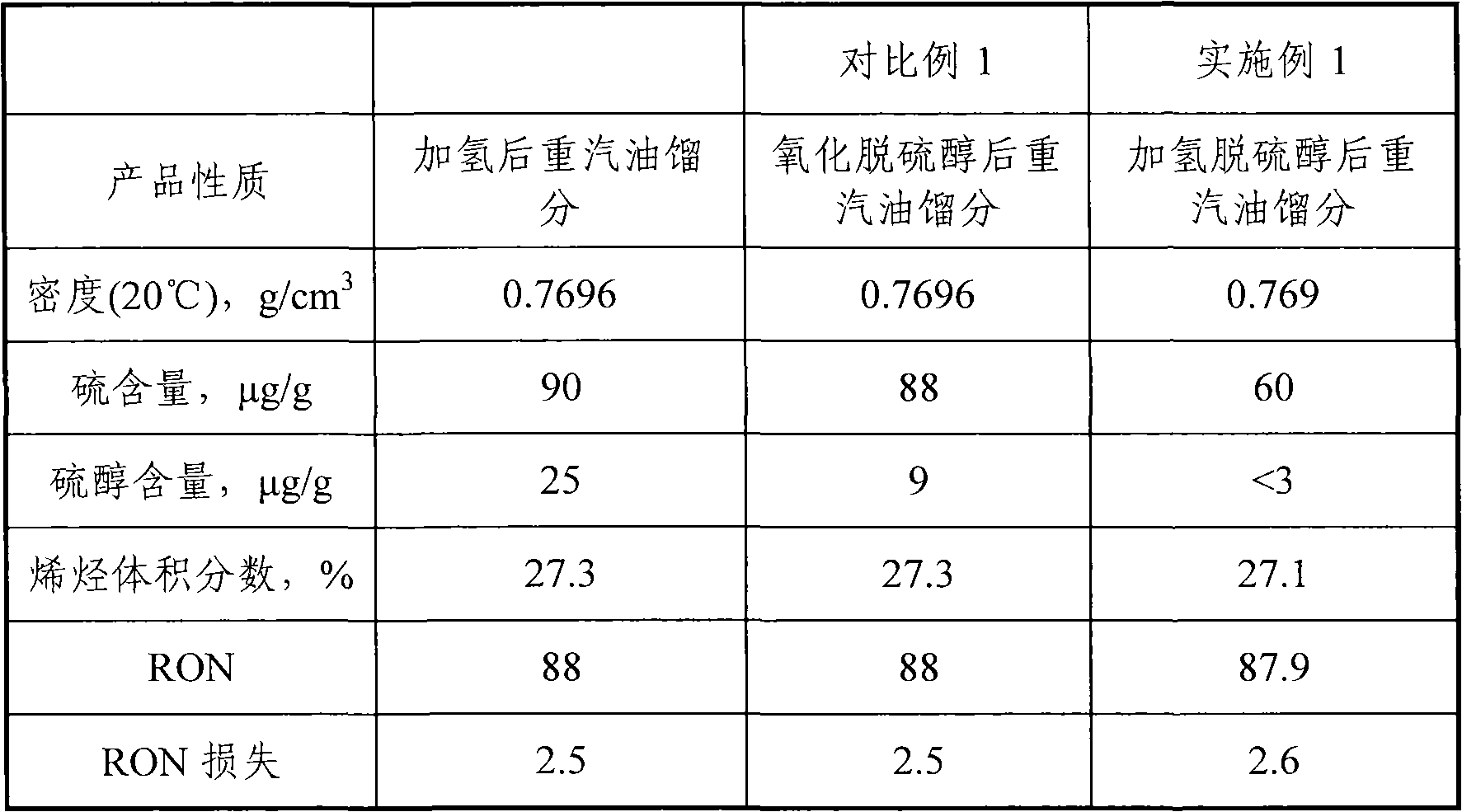

Embodiment 1

[0043] The process of gasoline fractionation and heavy fraction hydrodesulfurization is the same as that of Comparative Example 1. The difference is that the heavy gasoline fraction after hydrodesulfurization is introduced into the stripper. The stripping tower has a diameter of 32mm, a height of 4m, and a height of 1m above the feed, filled with Φ3mm metal rolling hole random packing. A total of 140g of sweetening catalyst RSS-1A is loaded below the feed inlet, the operating pressure of the stripper is 1.3MPa, the average temperature of the catalyst bed is 220°C, the feed rate is 700g / h, and the feed hydrogen-oil ratio is 25. Part of the product returns to the stripper after being heated by the reboiler, and part of the product is discharged with a discharge rate of 500g / h. The discharge from the top of the tower is condensed and then the non-condensable gas is discharged, and the liquid phase product is partially refluxed and partially discharged, with a reflux ratio of 0.5...

Embodiment 2

[0048]The processes of gasoline fractionation and heavy gasoline fraction hydrodesulfurization are the same as in Example 1. The heavy gasoline fraction after hydrodesulfurization is introduced into a stripper for hydrodemercaptanization, and the stripper and catalyst loading used are the same as in Example 1. The difference is that the operating pressure of the stripper is 0.9MPa, the average temperature of the catalyst bed below the feed is 200°C, the feed rate is 700g / h, the hydrogen-oil ratio of the feed is 10, and the output at the top and bottom of the tower is 400g / h. The discharge from the top of the tower is condensed and then the non-condensable gas is discharged, and the liquid phase product is partially refluxed and partially discharged, with a reflux ratio of 0.2. The top discharge is further stripped to remove the H 2 S is then mixed with sweetened heavy gasoline fraction products to obtain sweetened heavy gasoline fractions, the properties of which are shown in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com