Arsenic collecting system for dioxin-containing smelting flue gas and method thereof

A technology for smelting flue gas and flue gas, which is applied in separation methods, chemical instruments and methods, gas treatment, etc. It can solve the problems of low recovery rate of non-ferrous metals and failure to remove dioxins, etc., and achieve improved removal effect and resource utilization The effect of better efficiency and lower acid dew point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

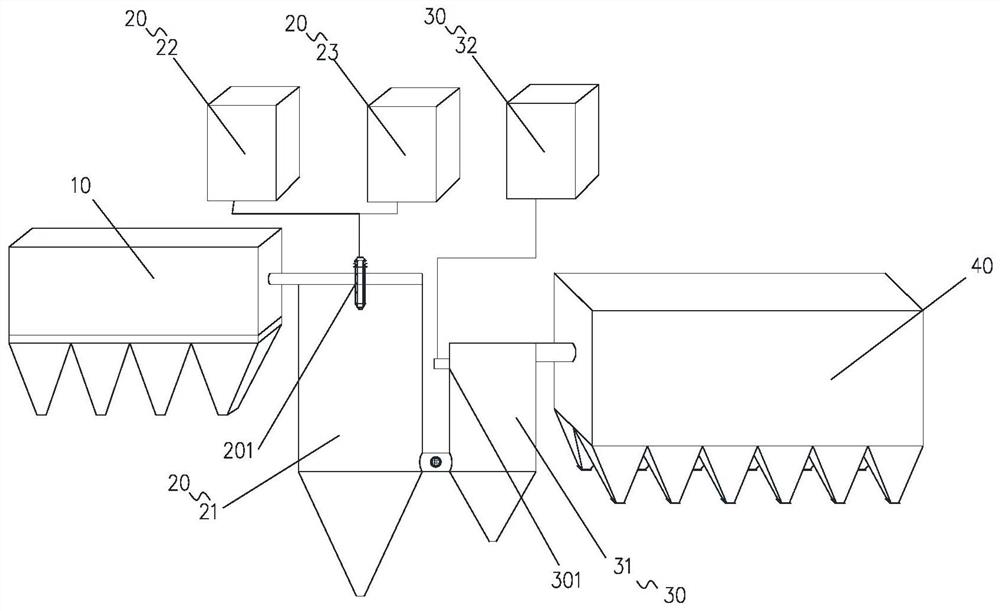

[0050] use figure 1 The middle system collects arsenic. The arsenic collection steps are as follows:

[0051] Bottom-blown converter smelting flue gas in recycled copper blowing section, initial flue gas volume is 45000Nm 3 / h, the flue gas contains arsenic trioxide (volume fraction 0.53%), sulfur trioxide (volume fraction 0.1%) and dioxin-like pollutants (≈5ngTEQ / Nm 3 ), the concentration of copper, lead and zinc and other non-ferrous metal dust is about 3270mg / Nm 3 .

[0052] After passing through the waste heat boiler, the high-temperature flue gas at 450°C enters the filter dust collector (including 800 high-temperature resistant metal filter cartridges set in parallel, and the filter area of the dust collector is 2000m2) 2 ), and return the non-ferrous metal dust to the converter for smelting. Among them, the filter dust collector is a bag filter formed by a stainless steel particle sintered filter cartridge provided by Chengdu Yitai Technology Co., Ltd. The backfl...

Embodiment 2

[0058] Side-blown converter smelting flue gas in the secondary copper blowing section, the initial flue gas volume is 40,000Nm 3 / h, the flue gas contains arsenic trioxide (volume fraction 0.27%), sulfur trioxide (volume fraction 0.16%) and dioxin pollutants (≈3ngTEQ / Nm 3 ), the concentration of copper, lead and zinc and other non-ferrous metal dust is about 1820mg / Nm 3 ,' After passing through the waste heat boiler, the high-temperature flue gas at 430 °C enters the filter dust collector (including 1200 high-temperature resistant ceramic filter cartridges set in parallel, and the filter area of the dust collector is 1500m 2 ), and return the copper-containing dust to the converter for smelting. Among them, the filter dust collector is a bag filter formed by a ceramic fiber filter cartridge provided by Shandong Industrial Ceramics Research and Design Institute Co., Ltd. The backflush pressure is 0.6Mpa, and the flow rate of the smelting flue gas in the filter dust collector...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com