Patents

Literature

86 results about "Arsenic Sesquioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

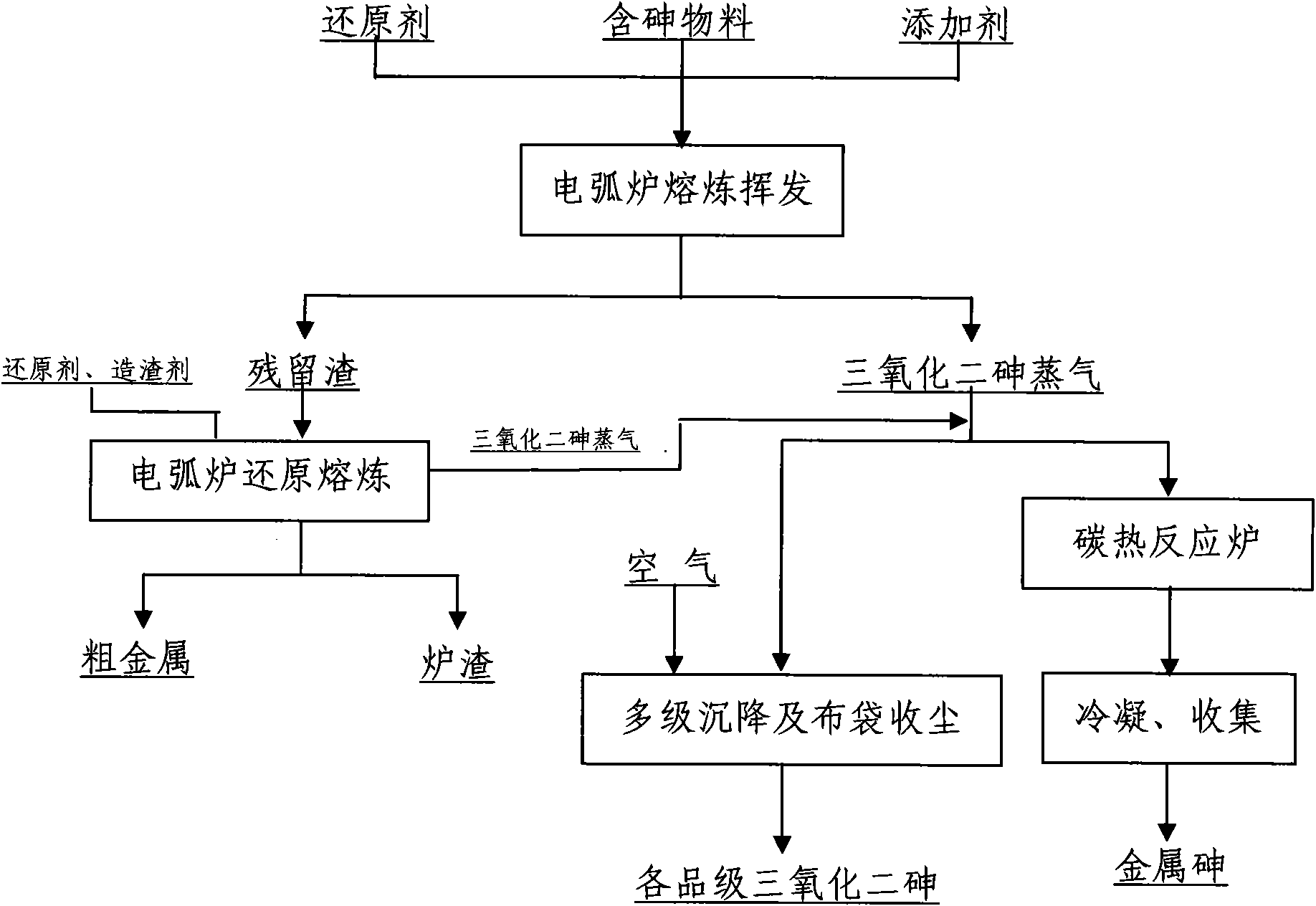

Method for treating arsenic-containing material by using electric arc furnace

InactiveCN101921921AGood environment interfaceIncrease volatilityProcess efficiency improvementSlagArsenic

The invention relates to a method for treating an arsenic-containing material and comprehensively recovering arsenic and other valuable metals by using an electric arc furnace. The method comprises the following steps of: adding a material containing arsenic trioxide into the electric arc furnace; adding a certain proportion of reducing agents and additives according to the components of the arsenic-containing material; keeping a certain pressure and temperature in the furnace to ensure that the arsenic trioxide in the material is fully volatilized; allowing the volatilized arsenic trioxide steam to pass through two paths so as to obtain high-quality arsenic trioxide and metallic arsenic respectively; and adding slag forming constituents and the reducing agents into volatilized residues for smelting to further recover the valuable metals in the residues. The method of the invention can realize the volatilization of the arsenic trioxide and the recovery and smelting of other valuable metals only by the electric arc furnace and has the advantages of strong adaptability of equipment, short flow, simple operation, good comprehensive recovery and good working environment.

Owner:YUNNAN TIN GROUP HLDG

Method for separating copper, arsenic and nickel and purifying copper electrolyte

ActiveCN102345143AAchieve separationAchieve recyclingPhotography auxillary processesElectrolysis componentsElectrolytic agentPhysical chemistry

The invention discloses a method for separating copper, arsenic and nickel and purifying a copper electrolyte, The method comprises the steps of: firstly, controlling current density by sections, and removing copper through electrodeposition; after removing the copper through electrodeposition, and introducing sulfur dioxide in a solution to reduce pentavalent As into tervalent As; and evaporating and concentrating the reduced solution, cooling and crystallizing, and recycling arsenic trioxide and nickel sulfate, thus, copper, arsenic and nickel are separated from the copper electrolyte, and the copper electrolyte is purified. The method disclosed by the invention has the advantages of simple process, low cost, good purification effect and great reduction of black copper powder, and realizes the opening of the As in a process of purifying the copper electrolyte.

Owner:深圳慧欣环境技术有限公司

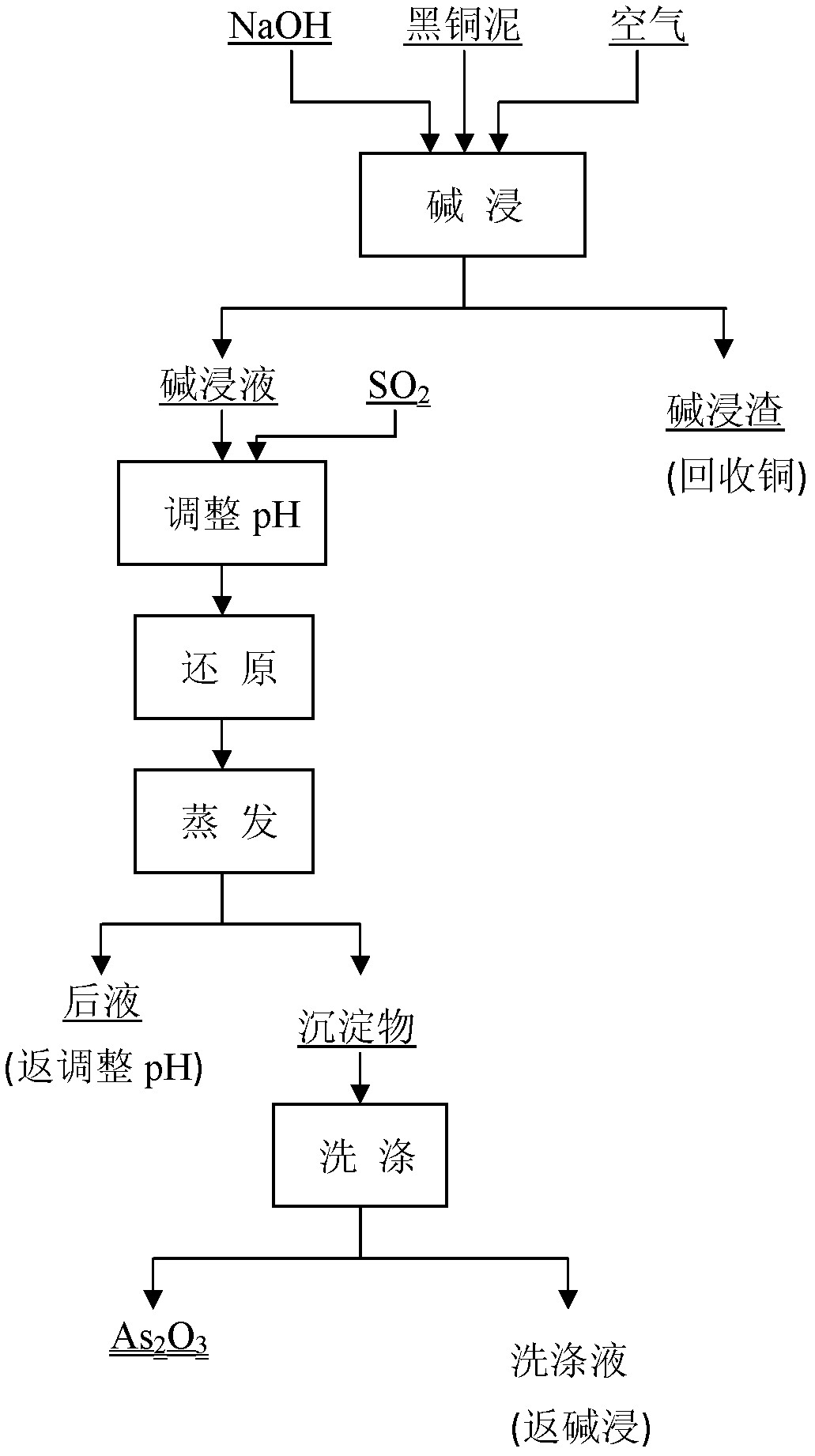

Method for preparing arsenic trioxide from black copper sludge

The invention discloses a method for preparing arsenic trioxide from black copper sludge, and aims to prevent a lot of arsenic-containing calcium sulfate waste residues generated by preparing arsenic trioxide from the black copper sludge from causing secondary pollution to the environment, simplify the process flow and reduce the production cost. The method comprises the following steps of: (1) preparing the black copper sludge into a leaching agent by using sodium hydroxide, namely, putting the black copper sludge into a sodium hydroxide solution in a liquid-solid ratio (ml / g) of 8:1 to 12:1, and stirring for 4-8 hours, wherein the concentration of the sodium hydroxide solution is 1-2mol / L, the temperature is 80-95 DEG C, and the amount of introduced air is 0.5-0.8m<3> / h; (2) adjusting the pH value of the leaching agent obtained in the step (1) to be -1 to 1 by using sulfuric acid, introducing sulfur dioxide gas for reduction for 1-2 hours, and evaporating, concentrating and crystallizing the solution after reduction to obtain a deposit; and (3) washing and drying the deposit obtained in the step (2) to obtain an arsenic trioxide product.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

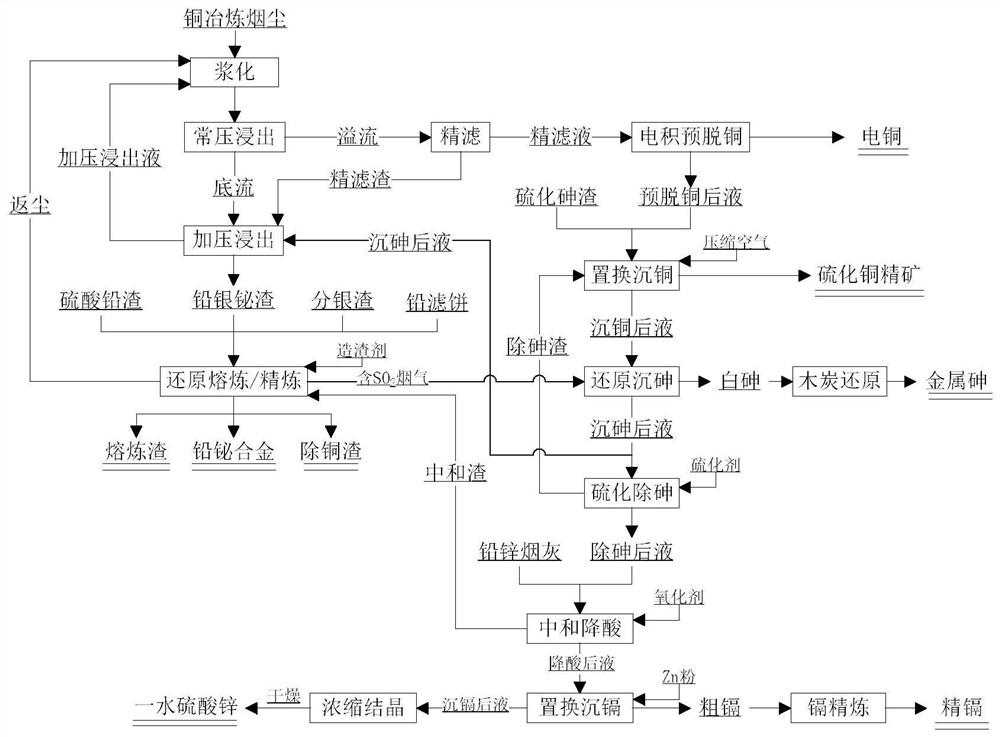

Copper smelting hazardous waste co-processing and valuable metal comprehensive recovery method

PendingCN112359213ALarge amount of processingIncrease consumptionPhotography auxillary processesProcess efficiency improvementSlagCopper sulfide

The invention provides a copper smelting hazardous waste co-processing and valuable metal comprehensive recovery method which comprises the following steps of firstly, carrying out atmospheric pressure-pressurization two-stage countercurrent leaching on copper smelting smoke to obtain atmospheric pressure leachate and lead-silver-bismuth slag, and carrying out electrodeposition pre-copper removalon the atmospheric pressure leachate to obtain electrocoppered and pre-decoppered liquid; then adding arsenic sulfide slag into the pre-decoppered liquid for replacement and copper precipitation to obtain copper sulfide concentrate and copper precipitation post-liquid; and introducing SO2-containing flue gas into the copper precipitation post-liquid for reduction and arsenic precipitation, and obtaining arsenic trioxide and arsenic precipitation post-liquid. According to the copper smelting hazardous waste co-processing and valuable metal comprehensive recovery method provided by the invention, the waste residue recycling and harmless processing degree is high, the valuable metal comprehensive recovery effect is good, no waste acid, waste water or hazardous solid waste is generated in thewhole process, a new path is provided for copper smelting hazardous waste co-processing, and wide application prospects are achieved.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD +1

Method for comprehensively utilizing arsenious waste liquor produced in copper-smelting process

InactiveCN103031442AReduce occupancyReduce investmentWater contaminantsWaste water treatment from metallurgical processLiquid wasteArsenate

A method for comprehensively utilizing arsenious waste liquor produced in a copper-smelting process. The method comprises the following steps: adding magnesium oxide to raw material which is the arsenious waste liquor formed during the production process of fire copper-smelting enterprises, reacting to obtain MgSO4 solution and Mg3(AsO4)2 filter residues; purifying the Mg3(AsO4)2 filter residues, drying and grinding to obtain a magnesium arsenate product; concentrating the MgSO4 solution to a saturation state to separate solid As2O3 out, purifying and drying to obtain an arsenic trioxide product; crystallizing the MgSO4 solution, purifying to remove the residual As2O3, so as to obtain a magnesium sulfate heptahydrate product; and roasting the magnesium arsenate product, collecting smoke which is generated during roasting, cooling to obtain the arsenic trioxide product, and collecting the roasted residues to finally obtain a magnesium oxide product. The method is simple in process, realizes the comprehensive utilization of the arsenious waste liquor with small investment, reaches the effects of energy saving and emission reduction and has a resource recovery effect.

Owner:林建忠

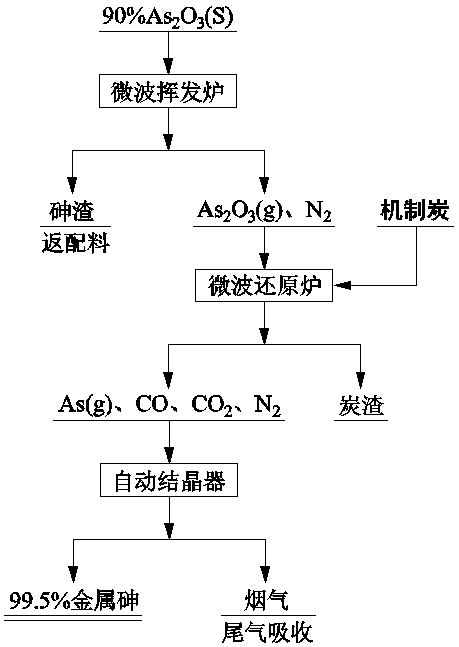

Technology and device for preparing metal arsenic from crude white arsenic

ActiveCN110747355AImprove thermal efficiencyReduce manufacturing costMicrowave heatingProcess efficiency improvementWhite arsenicEnvironmental engineering

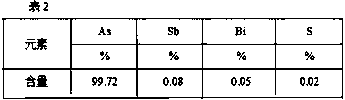

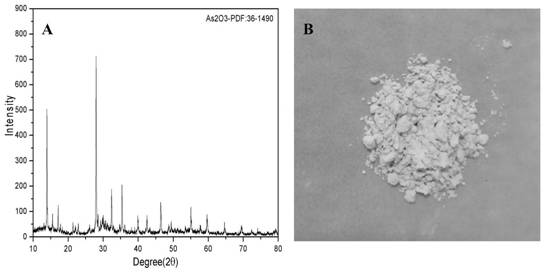

The invention provides a technology and device for preparing metal arsenic from crude white arsenic. The technology comprises the following technological steps: volatilizing crude arsenic trioxide ashcontaining As2O3 more than or equal to 90% at 600-700 DEG C to obtain arsenic trioxide steam, reducing the arsenic trioxide steam into arsenic steam by a reduction furnace accommodating machined carbon heated to 700-800 DEG C, and condensing the arsenic steam into metal arsenic containing As more than or equal to 99.5% by a crystallizer at 350-420 DEG C. The microwave metallurgy technology is applied to the technology of preparing metal arsenic from coarse white arsenic. The technology has the advantages of being low in production cost, high in thermal efficiency, environmentally friendly andenergy-saving, and product quality is good. The equipment has significant characteristics of high automation degree and high production efficiency.

Owner:SHANDONG HUMON SMELTING

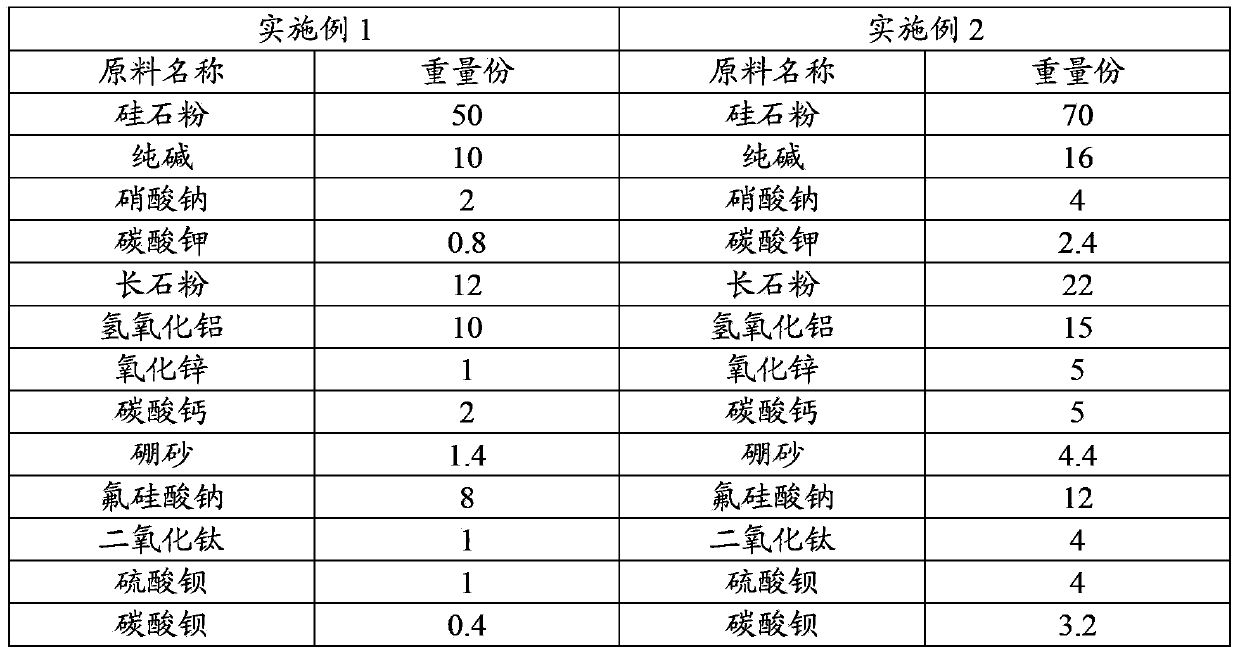

Soft-light colored glass product, and making method and special apparatus thereof

InactiveCN103466939AQuality improvementReduce volatilityGlass furnace apparatusCadmium CationPotassium carbonate

The invention relates to a soft-light colored glass product, and a making method and a special apparatus thereof. The soft-light colored glass product is made through using the following raw materials, by weight, 50-70 parts of silica powder, 10-16 parts of sodium carbonate, 12-22 parts of feldspar powder, 10-24 parts of aluminum hydroxide, 1-12 parts of zinc oxide, 4-24 parts of calcium carbonate, 1.4-12 parts of borax, 8-16 parts of sodium fluosilicate, 0.8-5.8 parts of potassium carbonate, 0.4-4 parts of sodium nitrate and 6.6-70 parts of an auxiliary material, and the auxiliary material comprises several selected from titania, barium carbonate, red lead, calcium phosphate, barium sulfate, magnesium oxide, fluorite, arsenic trioxide, antimony oxide, cobalt oxide, copper oxide, chrome oxide green, sodium antimonate, cadmium yellow, sulfur, uranium oxide, cerium oxide, cadmium red, cadmium sulfide, selenium powder and yttrium aluminum garnet. The making method comprises the following steps: 1, melting ingredients; 2, molding; and 3, cutting, annealing, examining, and packaging. The soft-light colored glass product has a long service life, required raw materials do not pollute the environment, and the soft-light colored glass product can be a lamp tube, a lamp cover or a lamp, and is used in lighting or entertainment lighting fittings.

Owner:申英良

Method for separating lead, arsenium and copper in high-lead high-arsenium copper slag

ActiveCN111154984AReduce consumptionRealize separation and recoveryArsenic sulfidesArsenic oxides/hydroxides/oxyacidsSmelting processSulfidation

The invention discloses a method for separating lead, arsenium and copper in high-lead high-arsenium copper slag. The method includes the steps that the high-lead high-arsenium copper slag and accessories are added into a smelting furnace to be smelted at the temperature of 1,000-1,100 DEG C; arsenic trioxide and arsenic sulfide generated in the smelting process volatilize into smoke dust; the copper and the lead are vulcanized into sulfide, and the sulfide is precipitated at the bottom of the furnace to form lead copper matte; the arsenium is separated; lead sulfide in the obtained lead copper matte is oxidized into lead oxide to form high-lead slag to be recovered; low-lead copper matte left at the bottom of the furnace is blown to form crude copper; and the lead and the copper are separated. The method is short in process and high in treatment efficiency, harmful matter does not directly make contact with people in the whole treatment process, and therefore the perniciousness of theharmful matter is greatly reduced. The consumption of additional reagents is avoided, the copper, the lead and the arsenium can be well separated, and the high recovery rate is achieved. All elementsin the high-lead high-arsenium copper slag are efficiently separated under the conditions of being low in cost, low in consumption, short in process and free of pollution, and good social and economic benefits are achieved.

Owner:HENAN YUGUANG GOLD & LEAD

Sample preparation method for measuring impurity element in high-purity arsenic by ICP-MS method

ActiveCN102072833APreparing sample for investigationMaterial analysis by electric/magnetic meansPhysical chemistryMass Spectrometry-Mass Spectrometry

The invention discloses a sample preparation method for measuring an impurity element in high-purity arsenic by an inductively coupled plasma-mass spectrometry (ICP-MS) method, and relates to the technical field of material analysis. The method comprises the following steps of: putting the high-purity arsenic into a special container; introducing oxygen at a certain temperature to form arsenic trioxide and sublimating to remove the arsenic; remaining the impurity element with low steam pressure in the container; resolving the remaining solution through electronic-grade nitric acid; and fixing the volume by using dilute nitric acid. By the method, the interference to the matrix element arsenic can be completely eliminated. Compared with glow discharge-mass spectrometry (GD-MS) detection data, the detection data of a sample prepared by the ICP-MS method has the characteristics of high precision and high accuracy, and is practical and feasible.

Owner:洛宁中天利新材料有限公司

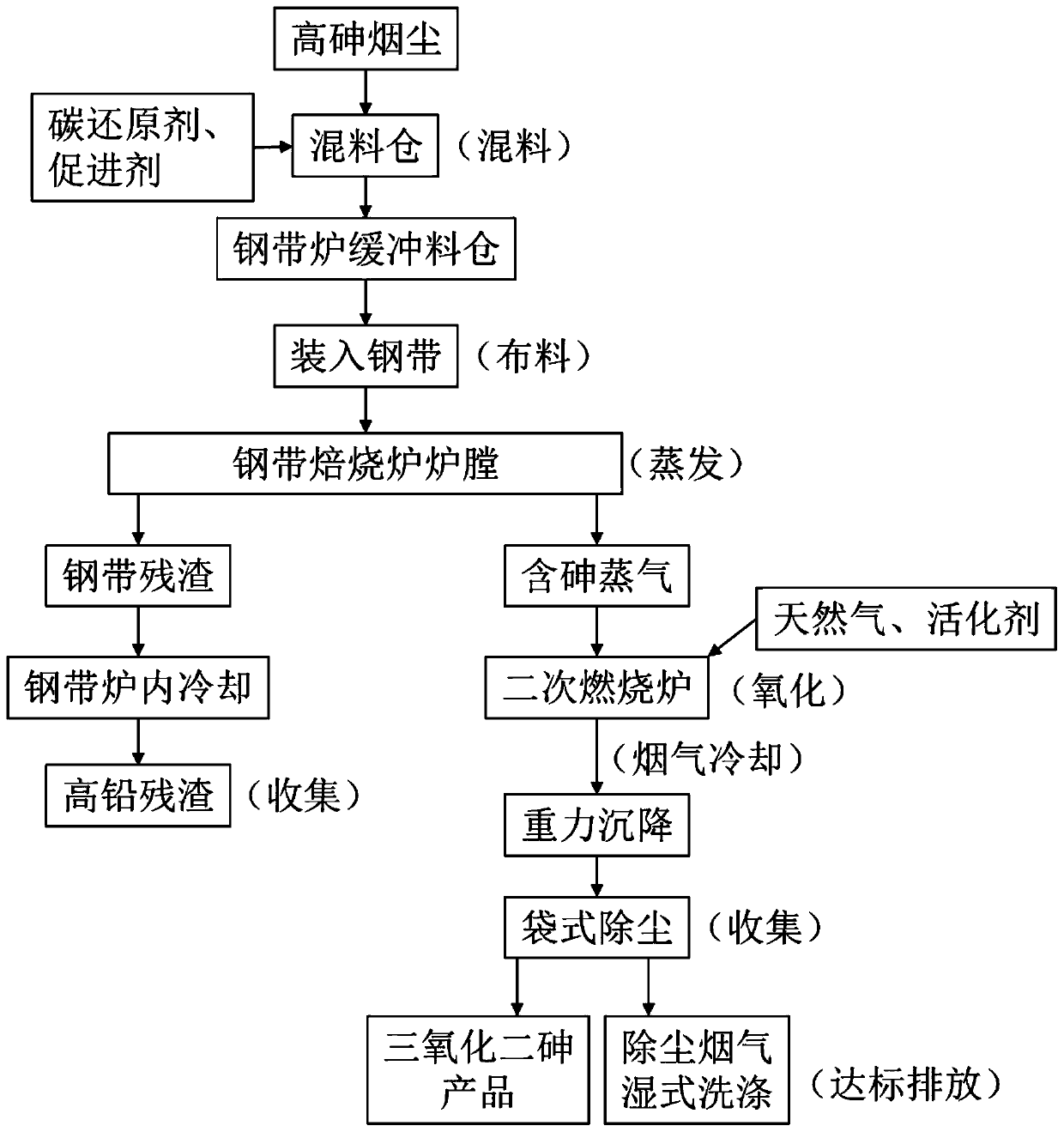

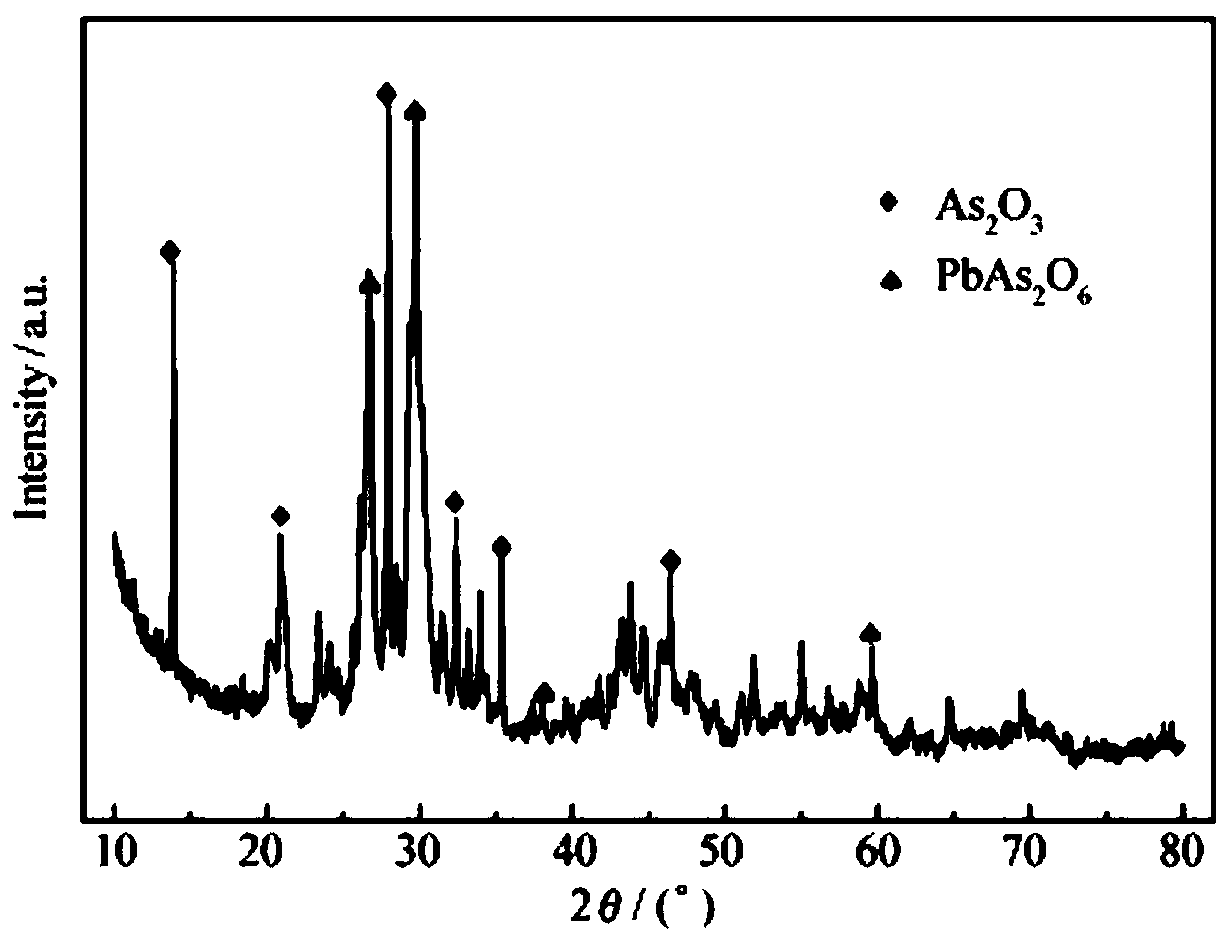

Method and device for recycling arsenic from high arsenic smoke

PendingCN111440954ARealize resourcesAchieve reductionCombination devicesArsenic oxides/hydroxides/oxyacidsReducing agentArsenide

The invention discloses a method for recycling arsenic from high arsenic smoke. The method comprises the steps that the high arsenic smoke and a carbon reducing agent are mixed to obtain a high arsenic smoke mixed material, and the high arsenic smoke mixed material is roasted in an inert atmosphere or a reducing atmosphere to obtain arsenious tail gas and high-lead ash residue; the arsenious tailgas is introduced into a combustion furnace, an activating agent is injected into the combustion furnace through a pulse powder injection valve for combustion, and high-temperature flue gas is obtained; and the high-temperature flue gas is condensed to obtain arsenic trioxide. A device for recycling arsenic from high arsenic smoke comprises a roasting furnace, the combustion furnace, a settling chamber, a dust remover, a spray tower and an externally-discharging chimney which sequentially communicate with one other; and the roasting furnace comprises a hearth and a continuous feeding device for guiding the high arsenic smoke into the hearth for roasting, and a material mixing cabin is arranged above the continuous feeding device. According to an arsenic removal technology, the arsenic removal selectivity and stability are good, the arsenic removal efficiency reaches up to 96.0% and above, and arsenic compounds obtained by purification reach 98.0% and above.

Owner:河南昌宜有色金属有限公司

Treatment method and device for incineration arsenic-containing flue gas

PendingCN108339361ANo secondary pollutionNo heat pollutionCombination devicesArsenic oxides/hydroxides/oxyacidsTechnical gradeMaterials science

The invention discloses a treatment method and device for incineration arsenic-containing flue gas. The treatment method comprises the following steps: the incineration arsenic-containing flue gas ofwhich the temperature is higher than 313 DEG C is introduced in a ceramic tube dust collector for dust collection, the flue gas after dust collection enters a mixing chamber, liquid nitrogen is introduced in the mixing chamber, and is in reverse contact with the flue gas to reduce the temperature of the flue gas to 30 DEG C, part of arsenic trioxide particles separated out through temperature reduction are sedimentated to the bottom of the mixing chamber to be discharged, the rest of arsenic trioxide particles enter an electric dust collector along with the flue gas to complete collecting, andthe flue gas after arsenic removal is directly discharged. A large amount of heat is absorbed through vaporization of liquid nitrogen, and the solidification range of amorphous arsenic trioxide is quickly crossed, so that crystal form arsenic trioxide is obtained to the maximum limit; liquid nitrogen entering the flue gas does not react with a gas component, and the chemical property of the gas component is not changed; arsenic is collected with electricity and is only removed; and no water is used in the whole process, so that water consumption and the subsequent water treatment cost are reduced greatly, an industrial arsenic trioxide product is produced, and environmental benefits and social benefits are improved.

Owner:KUNMING UNIV OF SCI & TECH

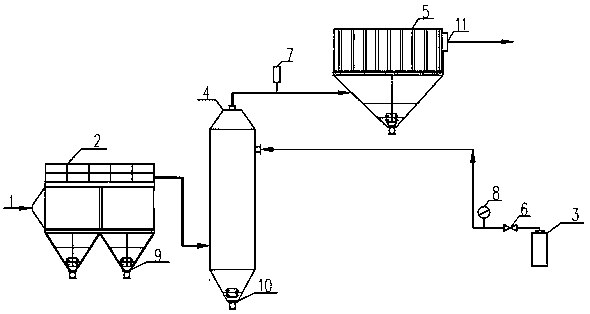

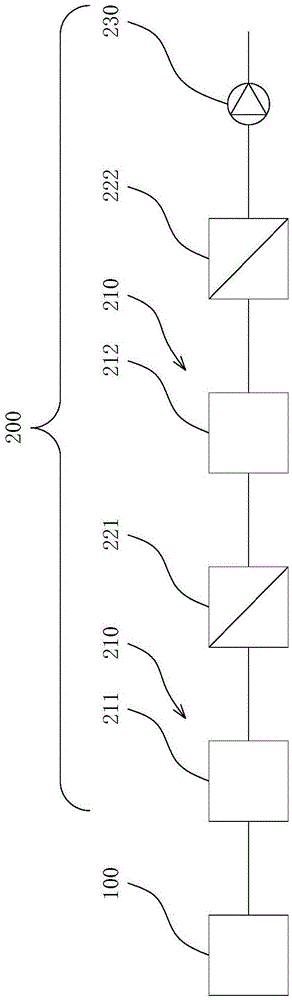

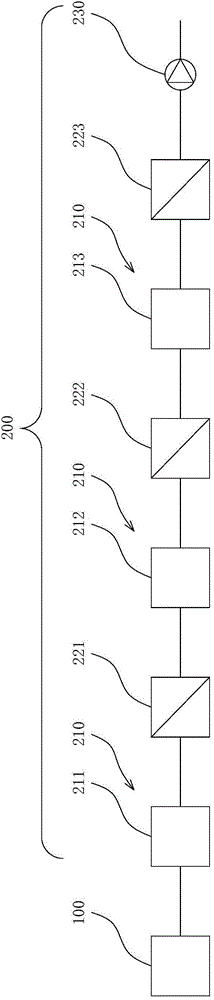

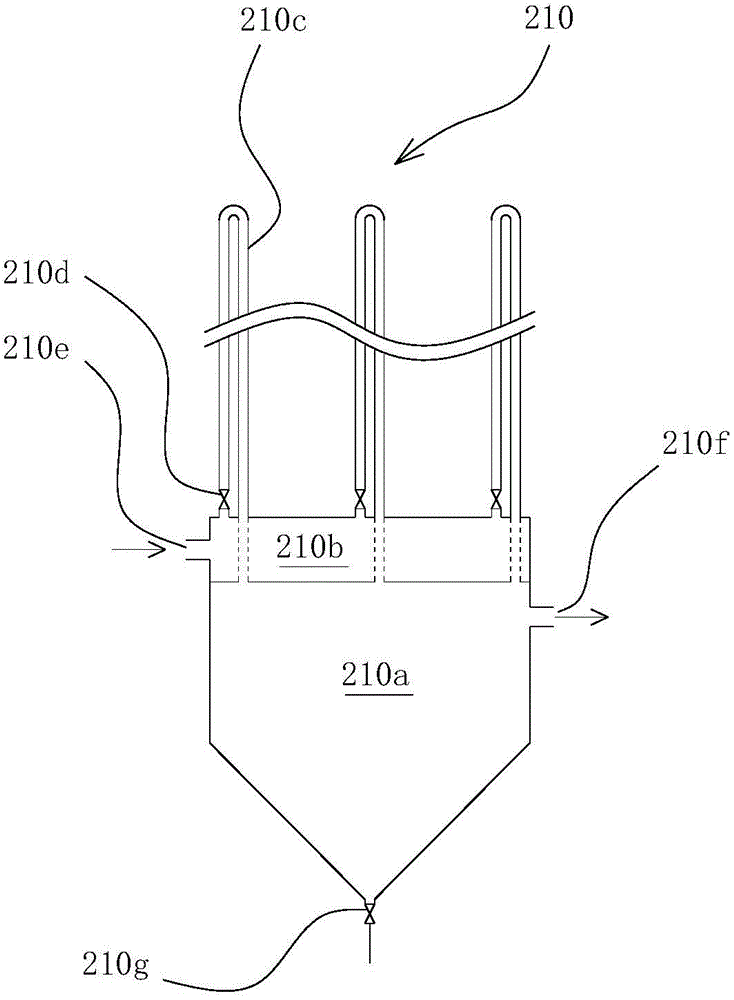

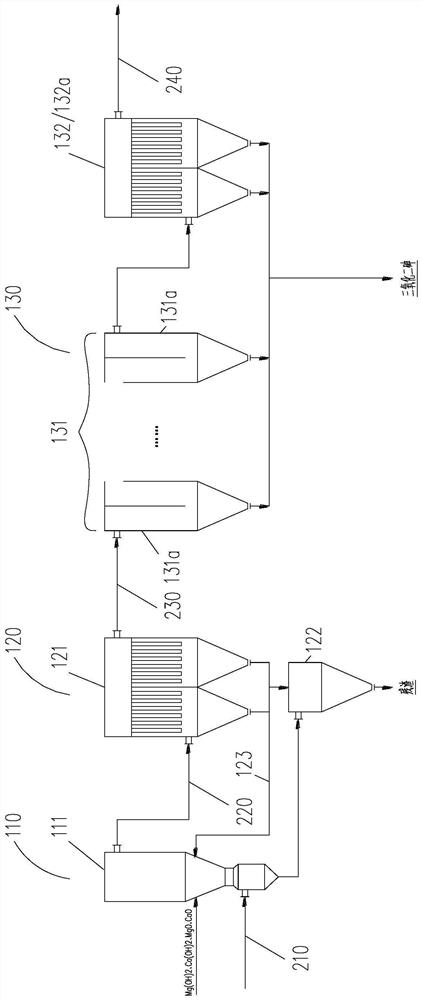

Lead anode mud melting high temperature furnace gas grading temperature control dust collection purifying technology

The invention discloses a lead anode mud melting high temperature furnace gas grading temperature control dust collection purifying technology. The technology is carried out to respectively obtain highly pure arsenic trioxide and antimony (III) oxide. The technology comprises the following steps: 1, inducing lead anode mud melting furnace gas generated in an industrial kiln into a furnace gas grading temperature control dust collection purifying device; 2, introducing the furnace gas into a first stage temperature control cooling unit in the device; 3, introducing a first dust carried furnace gas discharged from the first stage temperature control cooling unit into a first stage gas filtering unit; 4, introducing a furnace gas discharged from the first stage gas filtering unit into a second stage temperature control cooling unit; 5, introducing a second dust carried furnace gas discharged from the second stage temperature control cooling unit into a second stage gas filtering unit; 6, introducing a furnace gas discharged from the second stage gas filtering unit into a third stage temperature control cooling unit; and 7, introducing a third dust carried furnace gas discharged from the third stage temperature control cooling unit into a third gas filtering unit.

Owner:CHENGDU INTERMENT TECH

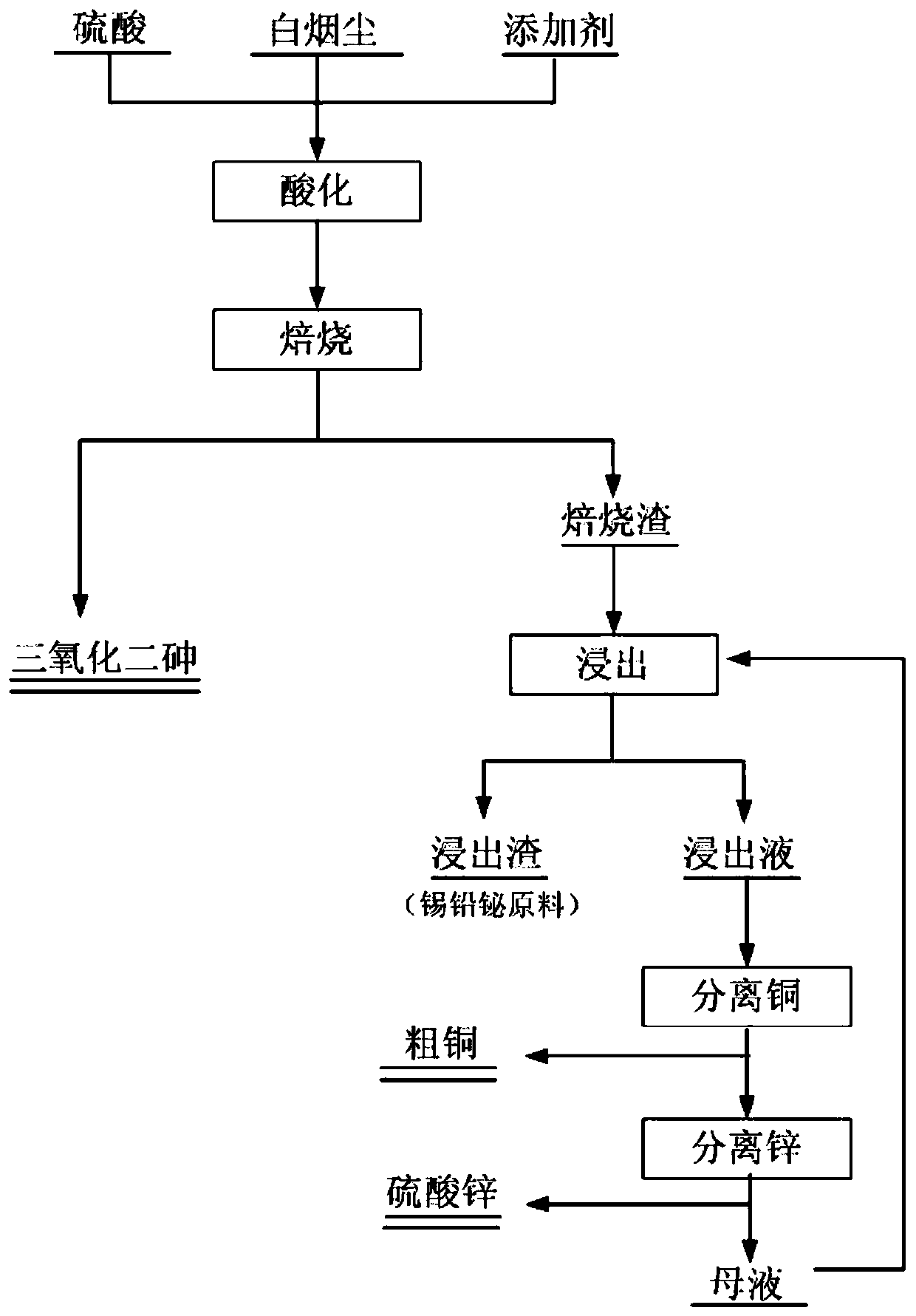

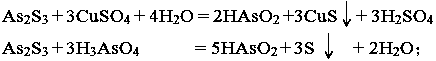

Method for selectively removing arsenic and recycling valuable metals from white smoke dust

InactiveCN110669941AInhibition formationEasy to separateZinc sulatesArsenic oxides/hydroxides/oxyacidsSlagSulfide

The invention discloses a method for selectively removing arsenic and recycling valuable metals from white smoke dust. The method comprises the following steps: mixing and acidifying arsenic-containing white smoke dust generated by copper smelting, sulfuric acid and an additive in a ratio of white smoke dust to sulfuric acid to the additive being 1 to (0.1-1) to (0.01-0.5); roasting the mixed acidified materials for 1-6 hours at a temperature of 250-600 DEG C, violating and introducing arsenic in the white smoke dust into smoke dust in the form of arsenic trioxide, roasting and transforming valuable metals into sulfate or metal oxides or sulfide for slagging, and realizing separation of arsenic and valuable metals, thereby accomplishing arsenic removal; adding water into roasted slag for leaching in a solid-to-liquid ratio being 1 to (2-7), controlling the pH value of leach liquor to be smaller than or equal to 7 at a leaching temperature being 80-95 DEG C, stirring and leaching for 2-4 hours, and filtering; and recycling copper and zinc from filtrate, and recycling other metals from filter slags. The method disclosed by the invention is good in universality, is wide in raw material adaption, is good in value metal and arsenic separation effect, and is simple in value metal recycling process.

Owner:云南锡业研究院有限公司 +1

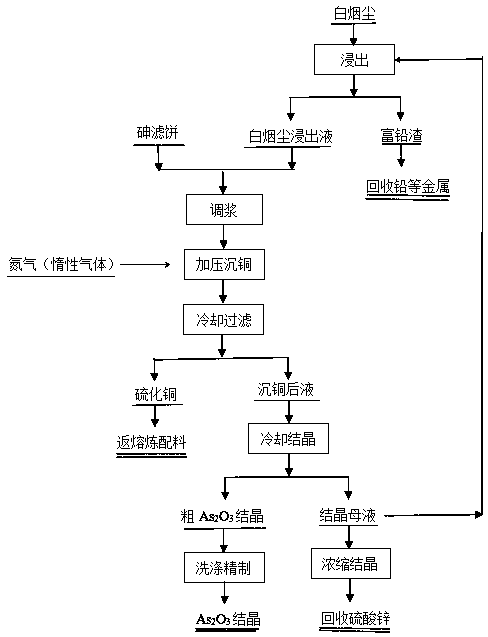

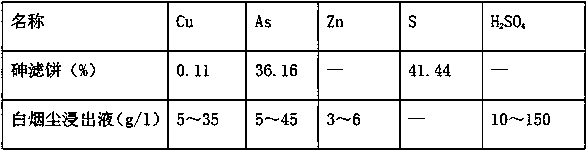

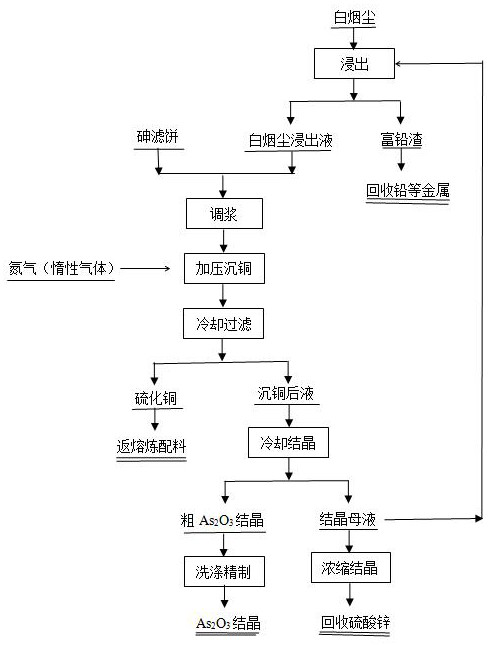

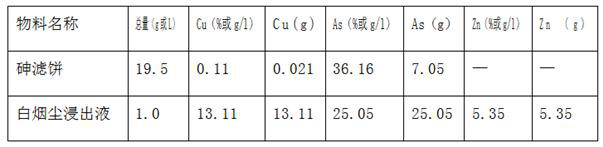

Method for recovering copper and arsenic from copper smelting white smoke dust leaching solution and arsenic filter cake

ActiveCN110983059ARealize resource utilizationHigh recovery rateProcess efficiency improvementPregnant leach solutionEngineering

The invention relates to a method for recovering copper and arsenic from a copper smelting white smoke dust leaching solution and an arsenic filter cake, and belongs to the technical field of comprehensive utilization of resources. The method comprises the following steps: a, pressurization copper deposition; b, cooling and filtering; c, cooling and crystallizing; and d, arsenic trioxide refining.The method has the following advantages that the resource utilization of the arsenic filter cake is realized, the recovery rate of copper and arsenic is high, the whole process is closed-loop circulation, and secondary pollution is avoided; meanwhile, sulfur dioxide does not need to be used for reduction, the production cost is saved, the production process is shortened, the time and the energy consumption are saved, and therefore the method has the outstanding advantages of economy, environmental protection, high efficiency, energy saving and the like.

Owner:黑龙江紫金铜业有限公司

Method of separating arsenic from copper slag through cooperation of high-arsenic material

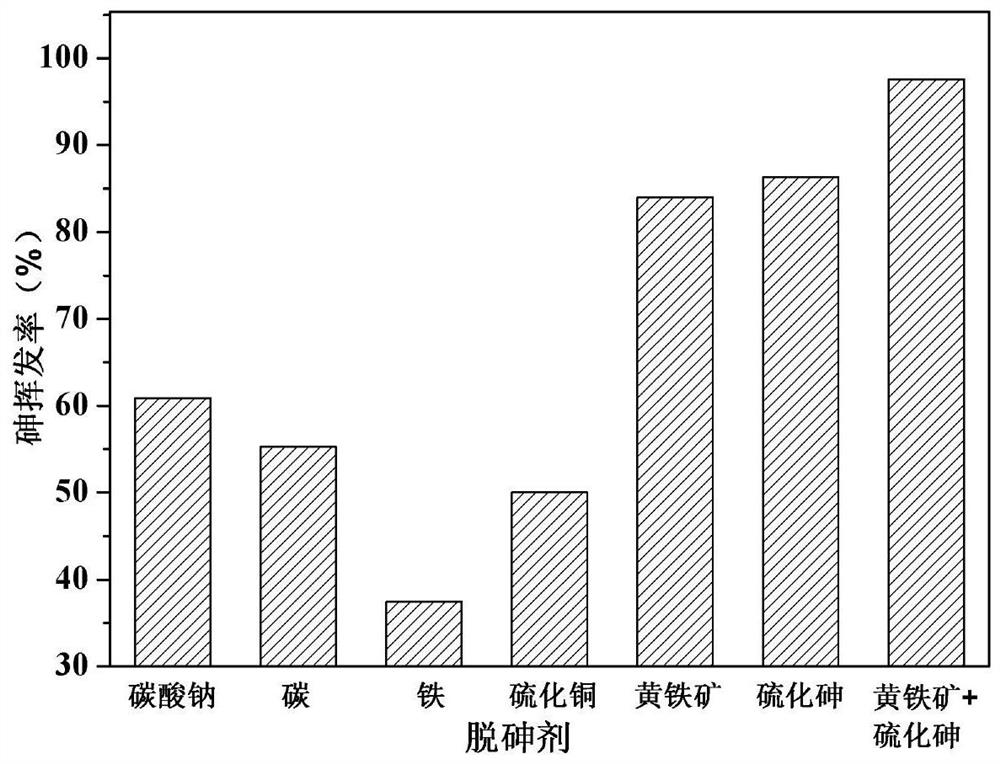

ActiveCN111996383AReduce arsenic levelsEasy to changeArsenic oxides/hydroxides/oxyacidsProcess efficiency improvementPyriteArsenic oxide

The invention discloses a method of separating arsenic from copper slag through cooperation of a high-arsenic material. The method comprises the steps of taking a mixed material of pyrite and arsenicsulfide slag as an arsenic remover, mixing the arsenic remover and copper slag evenly, and heating the mixture under an inert atmosphere at the temperature rising rate of 1-5 DEG C / min to 1100-1300 DEG C to be subjected to roasting to obtain mixed gas containing arsenic oxide and arsenic sulfide; introducing the air into the mixed gas to have a reaction at 800-900 DEG C to be oxidized to generatearsenic trioxide and sulfur dioxide; and finally conducting condensing to obtain an arsenic trioxide product. According to the method, the mixed material of pyrite and arsenic sulfide sliding groove serves as the arsenic remover and can destroy an arsenious vitreous body structure with high chemical stability in the copper slag, and arsenic is reduced into arsenic oxide and arsenic sulfide to be released; the problem that arsenic and copper slag in high-arsenic copper slag are hard to separate during actual production is solved; and the purposes of efficiently volatilize and directionally collecting arsenic and using waste to treat waste are achieved.

Owner:CENT SOUTH UNIV

Process for conducting resource recycling on copper and arsenic from arsenic-containing waste acid

InactiveCN105695743ARealize resourcesWorkmanship is feasibleProcess efficiency improvementEnvironmental engineeringArsenous acid

The invention discloses a process for conducting resource recycling on copper and arsenic from arsenic-containing waste acid. Resource recycling of the arsenic-containing waste acid is realized through the steps of neutralization and impurity removal, arsenic precipitation, washing, leaching, evaporation crystallization and preparation of arsenic trioxide through dissolution. According to the process, arsenic in the arsenic-containing waste acid is precipitated, converted and prepared into arsenic trioxide, and the defects of preparing arsenic trioxide by reducing copper arsenite with sulfur dioxide are overcome; high-standard arsenic trioxide is obtained, and treatment of the waste acid and reutilization of copper and arsenic resources are realized.

Owner:方端

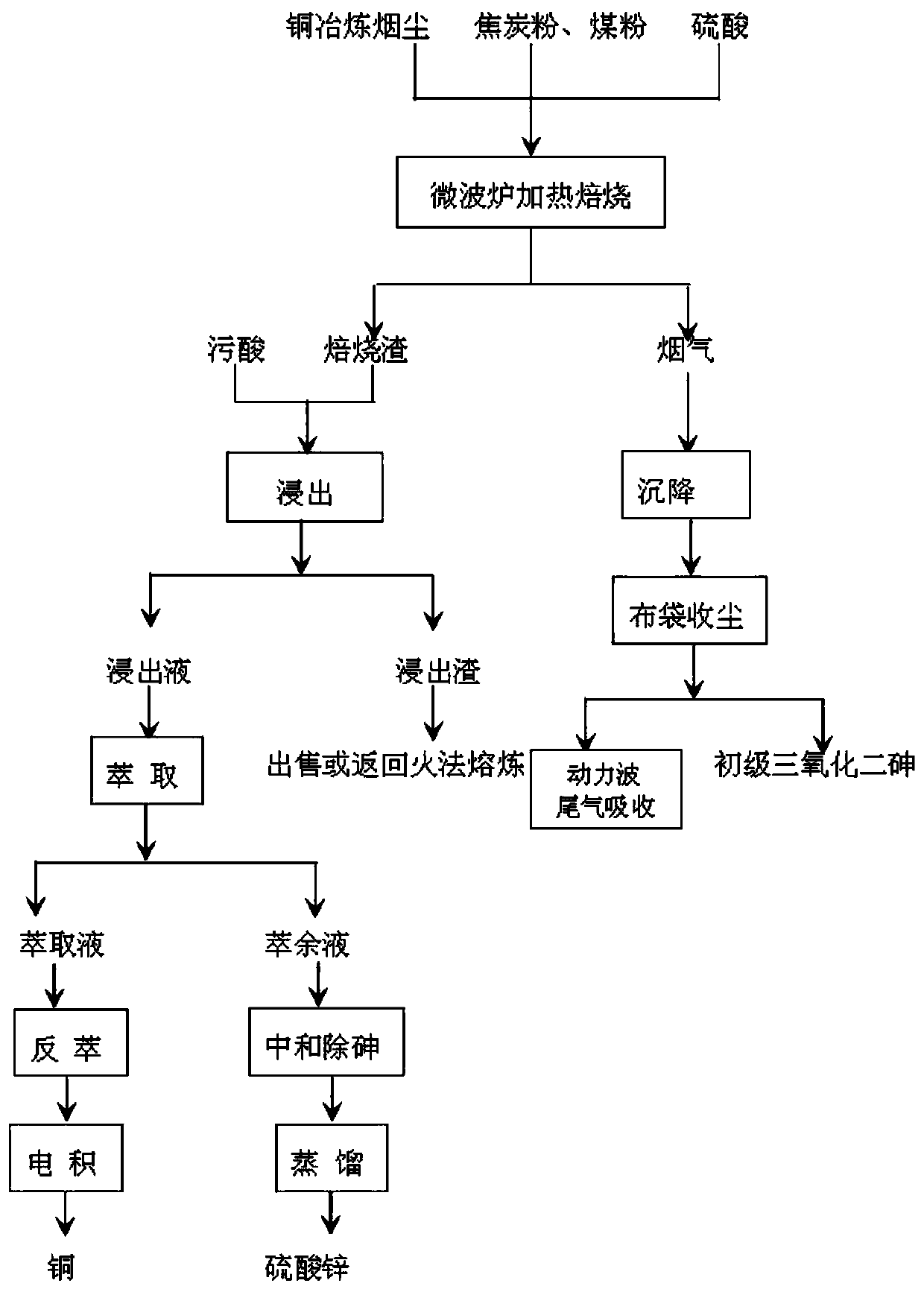

Process for efficiently treating copper smelting smoke dust

InactiveCN111235397AAchieve selective volatilizationAvoid Fugitive EmissionsPhotography auxillary processesProcess efficiency improvementIron sulfateSlag

The invention relates to a process for efficiently treating copper smelting smoke dust. The process comprises the steps that copper smelting smoke dust is added with 5-50% of coke powder or / and powdered coal and 10-40% of sulfuric acid and fed into a microwave oven, microwave heating roasting is carried out in a negative pressure state, arsenic trioxide is formed from arsenic in the copper smelting smoke dust and volatilized in the form of smoke, smoke is collected and settled, and an arsenic trioxide product is obtained; roasting slag is directly leached through acidic wastewater, zinc, copper and residual arsenic in the roasting slag are leached in a leaching solution, and tin, lead and other materials enter the leaching slag; and an extractant is added into the leaching solution to extract copper, after a crude copper product is produced through electrodeposition, calcium hydroxide is added into raffinate in the oxygen introducing environment to adjust the pH value to be 7-8, arsenic is precipitated, ferric sulfate is added for deeply removing arsenic, a zinc sulfate solution is obtained, and the zinc sulfate solution is concentrated and evaporated to obtain a zinc sulfate product. Arsenic, zinc, copper, tin and lead in smoke dust are separated in steps, the recovery rate of valuable metals is high, the process flow is short, and the operation is simple, convenient, safe andenvironmentally friendly.

Owner:云南锡业研究院有限公司

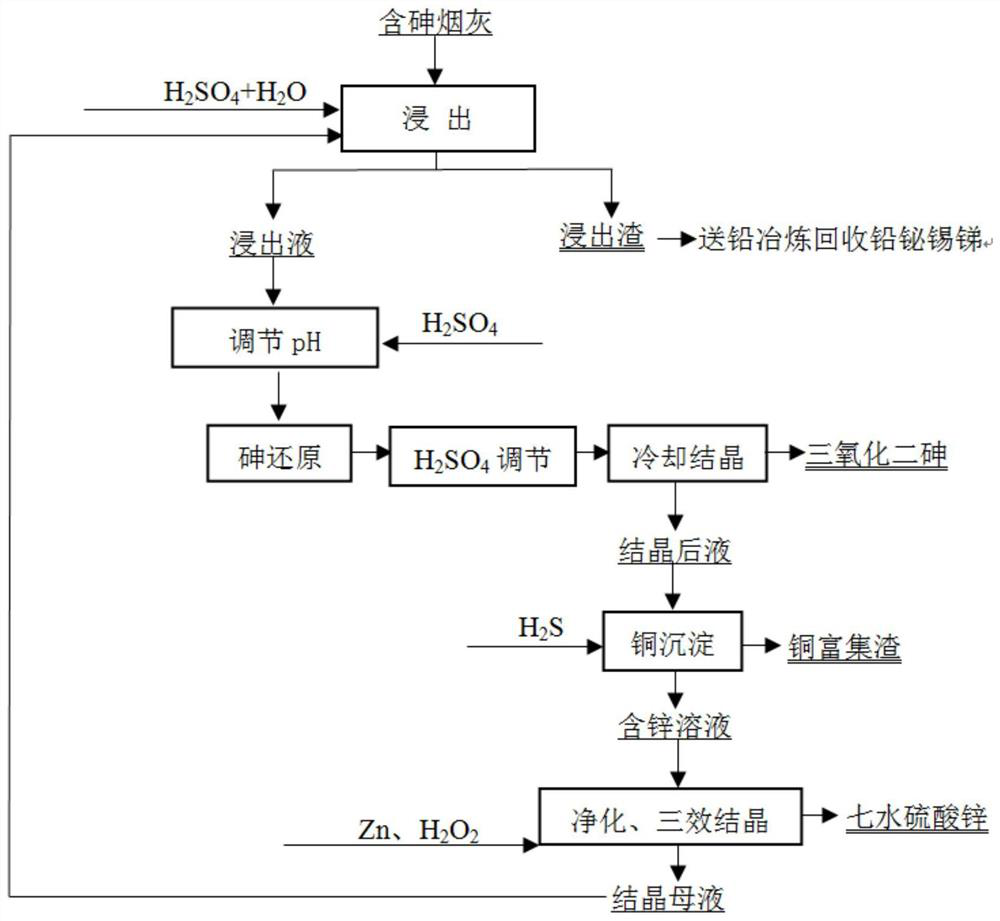

Method for recovering arsenic and valuable metals from arsenic-containing soot

ActiveCN113337720AAchieve recyclingHigh purityZinc sulatesArsenic oxides/hydroxides/oxyacidsLead smeltingSoot

The invention discloses a method for recovering arsenic and valuable metals from arsenic-containing soot. The method comprises the following steps: leaching the arsenic-containing soot through acid oxidation, enabling arsenic, copper and zinc to enter a solution, and enabling bismuth, lead, antimony and tin to enter a slag phase; selectively reducing arsenic from leachate through sulfur dioxide gas, recovering arsenic in the form of arsenic trioxide, and vulcanizing and precipitating the remaining solution containing copper and zinc through hydrogen sulfide gas to obtain copper-enriched slag and a zinc-containing solution; and performing purifying and impurity removal on the zinc-containing solution, performing concentrating and crystallizing to obtain a zinc sulfate heptahydrate product, and returning crystallization mother liquor to the arsenic-containing soot leaching process. According to the method, the arsenic in the arsenic-containing soot is efficiently recovered in the form of high-grade arsenic trioxide, the copper and the zinc are separated and recovered, enriched slag of lead, bismuth, tin, antimony and the like is obtained to serve as lead smelting raw materials, no industrial wastewater is discharged in the whole production process, no valuable hazardous waste is generated, and comprehensive treatment of the hazardous waste is facilitated.

Owner:CENT SOUTH UNIV

Automotive trim flame-resistant material and preparing method thereof

InactiveCN105037966AImprove flame retardant performanceQuickly turn offPolyethylene terephthalate glycolPolyvinyl alcohol

The invention discloses an automotive trim flame-resistant material and a preparing method thereof. The material comprises, by weight, 50-80 parts of polypropylene resin, 20-60 parts of anilmomethyl triethoxy silane, 10-40 parts of glass fiber reinforced polyethylene terephthalate, 20-30 parts of N-ethyl-p-toluenesulfonamide, 40-50 parts of barium sulfate, 40-50 parts of polyvinyl alcohol, 10-30 parts of dimethyl terephthalate, 20-60 parts of paraformaldehyde, 40-50 parts of arsenic trioxide, 2-8 parts of potassium oxide, 10-20 parts of dicyanodiamine, and 20-40 parts of adipic acid dihydrazide. According to the preparing method, the polypropylene resin, the anilmomethyl triethoxy silane, the glass fiber reinforced polyethylene terephthalate, the N-ethyl-p-toluenesulfonamide, the barium sulfate, the polyvinyl alcohol, the paraformaldehyde, the arsenic trioxide, the potassium oxide, the dicyanodiamine and the adipic acid dihydrazide are evenly mixed through a high-speed mixing machine for plasticizing fusion, dimethyl terephthalate injection is conducted at the same time, and the constituents are extruded after being mixed. The flame resistance of the automotive trim flame-resistant material is high.

Owner:浙江联益智能科技有限公司

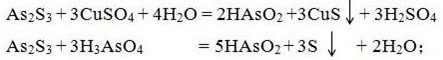

Method for transforming arsenic sulfide slag and curing and stabilizing resulting compound by means of microencapsulation

PendingUS20210078056A1Improve stabilityLow toxicityMaterial nanotechnologySilicaArsenate compoundNitrobenzene

The present disclosure provides a method for transforming an arsenic sulfide slag and curing and stabilizing the resulting compound by means of microencapsulation, comprising the following steps: (1) preparing arsenic trioxide from the arsenic sulfide slag as a raw material; (2) preparing 4-hydroxy-3-nitrophenylarsonic acid from the arsenic trioxide as a raw material; (3) preparing an iron-manganese dinuclear cluster metal arsenate compound having a porous structure; (4) subjecting the iron-manganese dinuclear cluster metal arsenate compound having a porous structure to surface coating with silicon; (5) synthesizing an Fe(0) / Al-SBA-15 mesoporous composite stabilizer by a hydrothermal reaction; and (6) subjecting the silicon coated iron-manganese dinuclear cluster metal arsenate compound to curing and stabilizing treatment by means of microencapsulation. The present disclosure involves transforming the arsenic sulfide slag into 4-hydroxy-3-nitrophenylarsonic acid and finally into a metal arsenate compound having a porous structure, which has the characteristics of good stability and low toxicity in comparison to conventional arsenic compounds. Thus, the toxicity associated with arsenic compounds can be greatly reduced.

Owner:BEIJING GEOENVIRON ENG & TECH

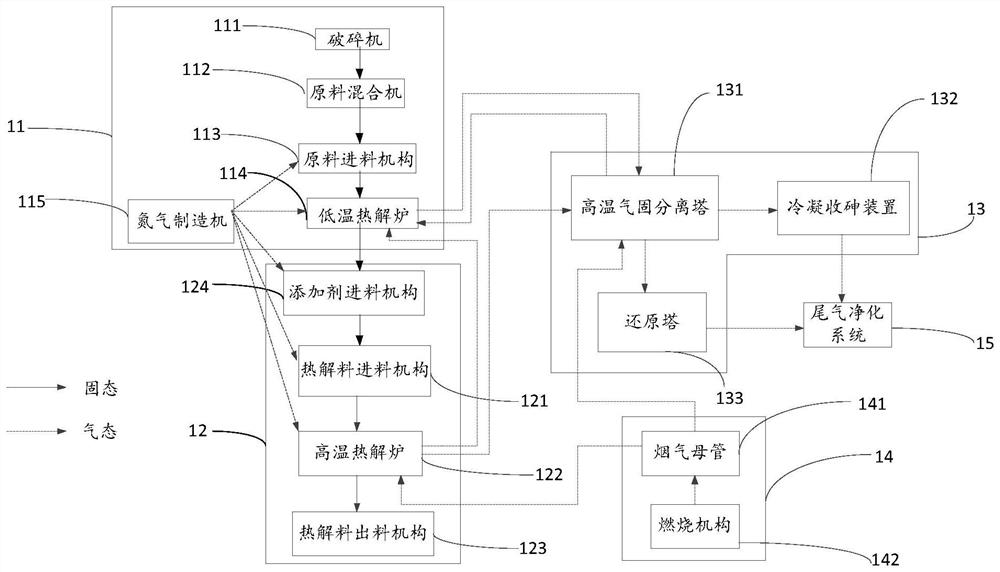

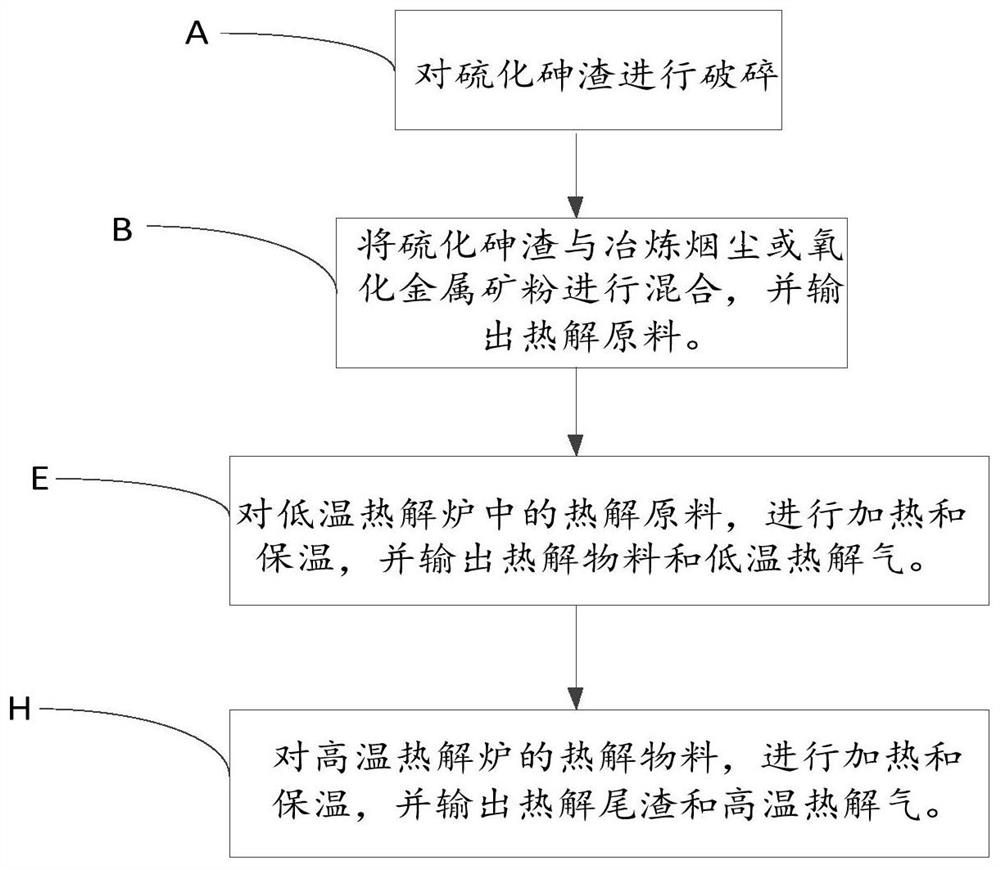

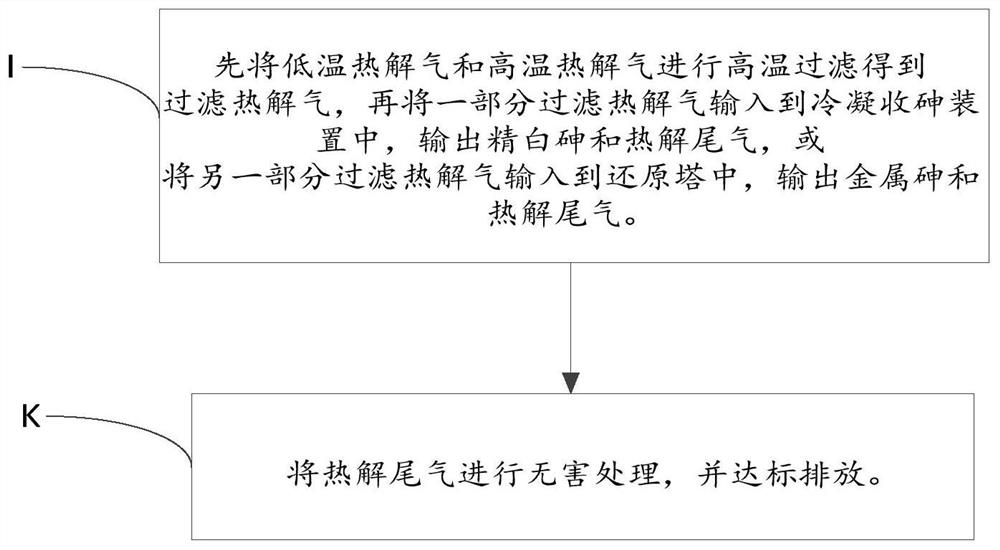

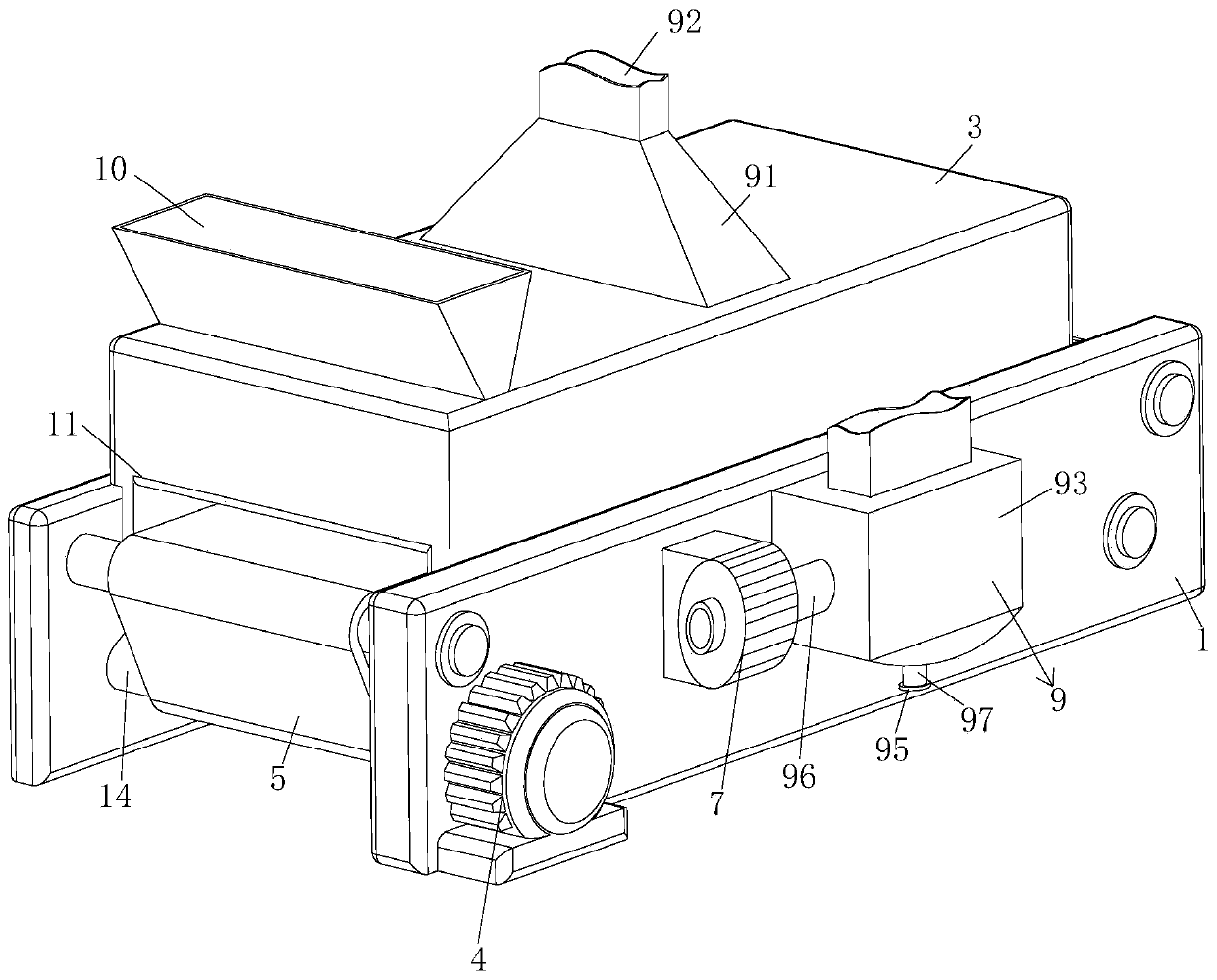

Synergistic treatment and utilization method for non-ferrous smelting arsenic-containing materials

ActiveCN113862493AConducive to inhibiting the formation ofAvoid pollutionProcess efficiency improvementNon-ferrous extractive metallurgySulfide

The invention provides a synergistic treatment and utilization method for non-ferrous smelting arsenic-containing materials. According to the method, arsenic sulfide in arsenic sulfide slag in a low-temperature inner cylinder generates solid metal sulfide and gaseous arsenic trioxide; solid arsenic trioxide in smelting smoke dust or oxidized metal mineral powder in a high-temperature inner cylinder is heated to be in a gaseous state; and the low-temperature inner cylinder and the high-temperature inner cylinder are infinitely close to an oxygen-free atmosphere, and carbon powder is input into the high-temperature inner cylinder. The synergistic treatment and utilization method for the non-ferrous smelting arsenic-containing materials has the advantage that various materials are subjected to synergistic treatment, arsenic removal and sulfur fixation, valuable metals in reactants are increased in value through a vulcanization mode, in addition, sulfur in the reactants is reserved, and subsequent pyrometallurgy is facilitated; compared with traditional furnaces such as fluidized beds, blast furnaces and reverberatory furnaces, the flue gas amount is extremely small, sulfur loss is small, and secondary pollution is low; and the adaptability is high, corresponding technological parameters and material adding proportions can be adjusted according to different non-ferrous metal smelting products, the effect is good, the technological process is simple, and industrial large-scale treatment can be realized.

Owner:红河砷业有限责任公司 +1

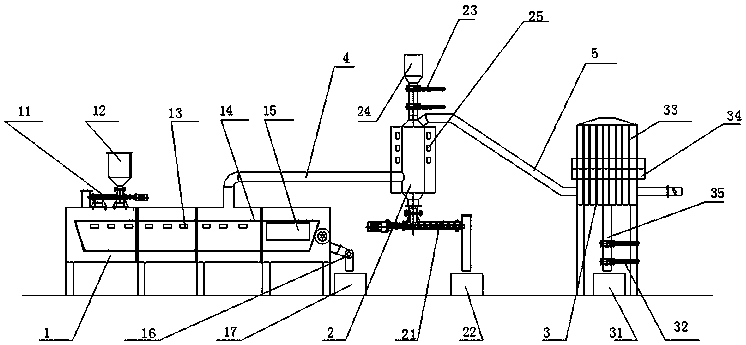

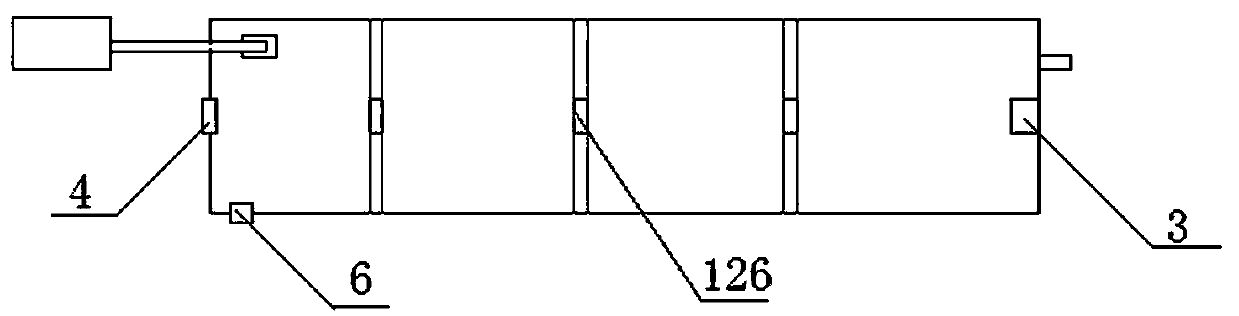

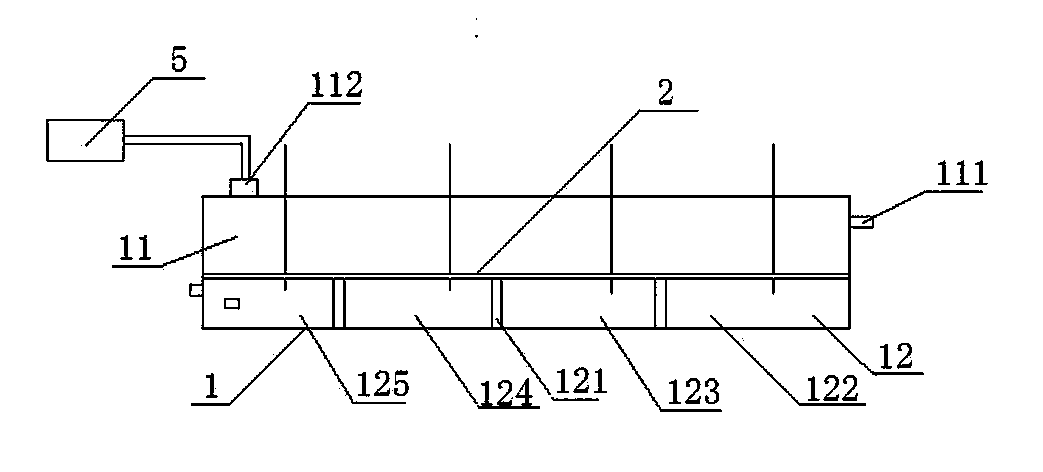

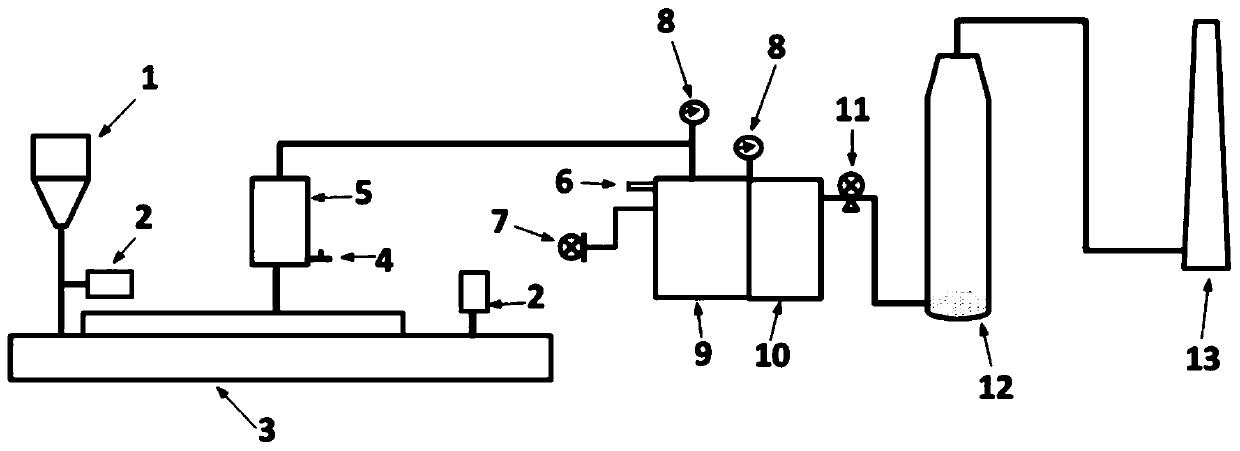

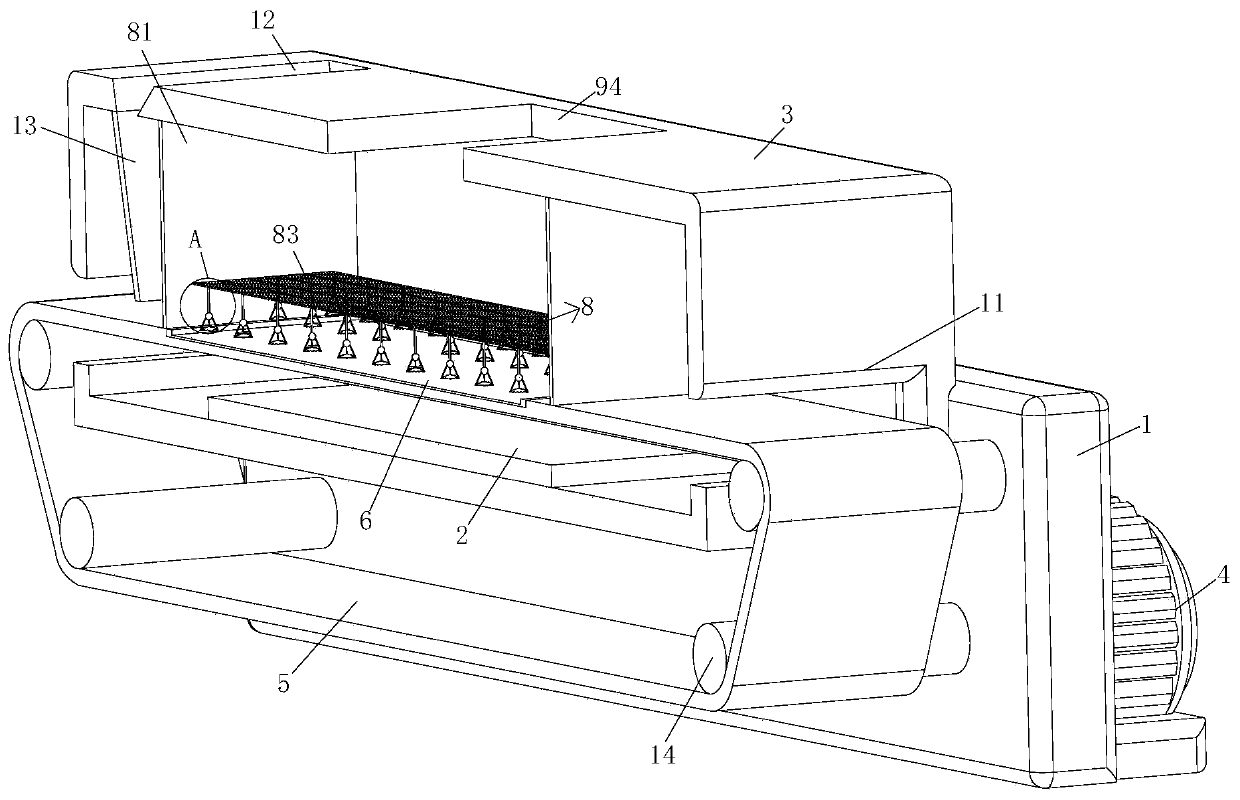

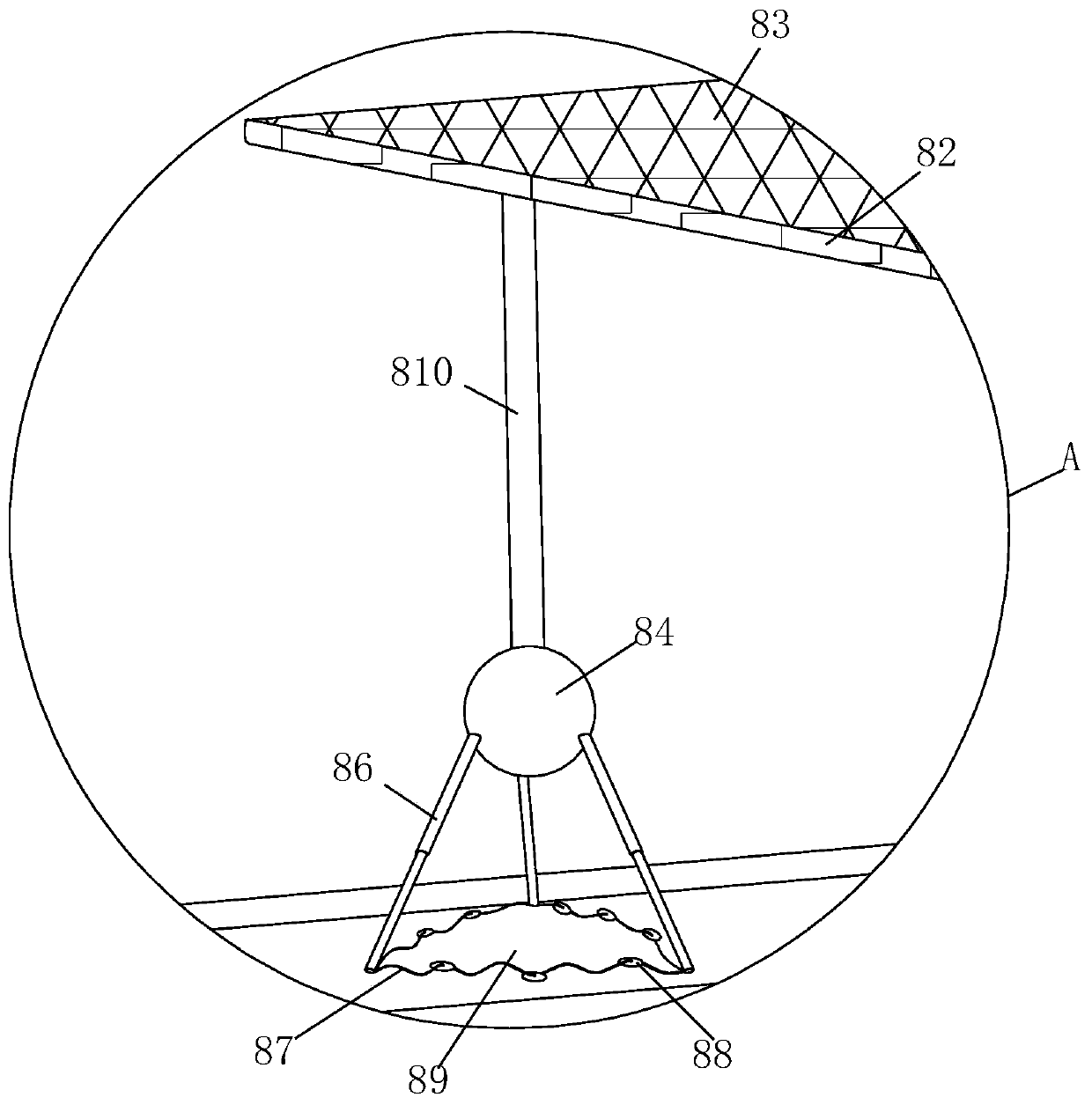

Method for distilling and purifying arsenic trioxide by full-automatic belt type electric furnace

PendingCN111498901ALayer changes in real timeSublimation fastSublimationArsenic compoundsDistillationPhysical chemistry

The invention provides a method for distilling and purifying arsenic trioxide by a full-automatic belt type electric furnace. The invention comprises a crude arsenic trioxide raw material and full-automatic belt type distillation and purification equipment used for purifying arsenic trioxide, wherein the full-automatic belt type distillation and purification equipment comprises side plates, a heating device, a box body, a motor, a transmission crawler belt, a material placing frame, a fan, a feeding hopper, a negative suction type micro-motion material raising mechanism and a collecting mechanism. The invention relates to the field of arsenic trioxide. According to the method for distilling and purifying arsenic trioxide by a full-automatic belt type electric furnace. A large-area tiling purification mode is designed; a special structure capable of layering sublimated materials according to the particle size change in the arsenic trioxide sublimation process is designed; therefore, theproblems that arsenic trioxide needs to be kept still to a certain extent, particles are mutually accumulated, the distillation and purification time is long, and the working efficiency is influencedto a certain extent in a common method for purifying and distilling arsenic trioxide by an electric furnace are effectively solved.

Owner:湖南中南黄金冶炼有限公司

A method for recovering copper and arsenic from copper smelting white smoke leach liquor and arsenic filter cake

ActiveCN110983059BRealize resource utilizationHigh recovery rateProcess efficiency improvementPregnant leach solutionEnvironmental engineering

The invention relates to a method for recovering copper and arsenic from copper smelting white smoke leach solution and arsenic filter cake, and belongs to the technical field of comprehensive utilization of resources. The method comprises the following steps: a, step of pressurizing copper precipitation; b, cooling and filtering; c, cooling and crystallization; d, refining diarsenic trioxide. The invention has the following advantages: the resource utilization of arsenic filter cake is realized, the recovery rate of copper and arsenic is high, the whole process is closed-circuit, and no secondary pollution will be generated; at the same time, the invention does not need to use sulfur dioxide for reduction, which not only saves production costs , and shorten the production process, save time and energy consumption, therefore, the present invention has the outstanding advantages of economy, environmental protection, high efficiency and energy saving.

Owner:黑龙江紫金铜业有限公司

Synthetic method for preparing arsenic trioxide through using arsenic-containing wastewater

The invention discloses a synthetic method for preparing arsenic trioxide through using 3-nitro-4-hydroxyphenylarsonic acid wastewater as a raw material. The method comprises the following steps: carrying out pretreatments comprising pH value adjustment, cartridge filtration and the like of arsenic-containing wastewater, allowing the obtained pretreated wastewater to enter the feed liquid cycle tank of a membrane experiment apparatus, and intercepting high-content arsenic-containing wastewater; adjusting the pH value of the obtained high-content arsenic-containing wastewater to 10-12 by using an alkali, adding a reducing agent A to reduce pentavalent arsenic to trivalent arsenic, and carrying out a reaction at 40-80DEG C for 6-10h; allowing a tail gas generated in the reaction to go through a reaction absorption tower for absorbing the tail gas; and concentrating a reaction liquid obtained after the reaction by adopting a triple effect concentrator to a volume being 1 / 4 of an original volume, adjusting the pH of the obtained concentrate by using an acid, stirring for slowly cooling to 40DEG C for crystallization, and filtering to obtain arsenic trioxide powder. The synthetic method for preparing arsenic trioxide through using wastewater as a raw material has the advantages of simple flow, low raw material investment, low cost, no generation of wastes, and environmental protection.

Owner:ZHEJIANG RONGYAO CHEM

Comprehensive recovery process for antimony smelting arsenic alkali residues

ActiveCN112941312AMeet the requirements for arsenic content in general demandHarmlessAlkali metal oxidesProcess efficiency improvementCalcium hydroxideSlag

The invention discloses a comprehensive recovery process for antimony smelting arsenic alkali residues. The comprehensive recovery process comprises the following steps of (1) crushing and briquetting, specifically, firstly breaking the antimony smelting arsenic alkali residues, then mixing the broken antimony smelting arsenic alkali residues with a reducing agent, a slag former and fuel, finely grinding the mixture, adding water for mixing and preparing the mixture into a block mass; (2) arsenic and antimony pyrogenic volatilization, specifically, calcining and volatilizing to obtain alkaline residues and an antimony-containing arsenic trioxide crude product; (3) alkaline residue leaching, specifically, firstly breaking the alkaline residues, finely grinding the broken alkaline residues, after adding water, carrying out heating leaching, solid-liquid separation, and washing to obtain silicon dioxide residues and an arsenic-containing alkaline solution; and (4) arsenic removal and purification of the alkaline solution, specifically, adding an arsenic removal agent and a purifying agent into the arsenic-containing alkali solution, heating for deep arsenic removal reaction, carrying out solid-liquid separation to obtain calcium arsenate / calcium hydroxide mixed salt and arsenic-removed alkali solution, and concentrating and crystallizing the arsenic-removed alkali solution to obtain solid sodium hydroxide / sodium carbonate mixed alkali. The method is high in arsenic and antimony volatilization rate, high in alkali recovery rate and extremely low in arsenic content, byproducts can be efficiently recycled, no three wastes are discharged, the cost is low, harmlessness and recycling of the arsenic alkali residues are achieved, and the method is suitable for large-scale industrial treatment.

Owner:刘义冬

Welding flux used in filigree gold tire welding cloisonné products and method for making cloisonne products

ActiveCN103624863BFiligree positioning is preciseHigh hardnessDecorative surface effectsSpecial ornamental structuresPolishingBluing

The invention relates to a welding powder used in filigree gold tire fusion welding cloisonné products and a method for making the cloisonne products. The method includes the steps of tire making, filigreeing, threading, welding, pickling, bluing, bluing, bright white glaze, bluing again, polishing, gold plating, etc., wherein the welding powder composition is: 55‑60% Gold, 6‑8% silver, 27‑32% red copper, 4‑7% cadmium, plus 22‑26% of the above weight of arsenic trioxide; when pickling, pickle the welded gold body three times, each time 10‑ 12 minutes; the sintering temperature is 790-820°C after bluing. The flux used for welding in the present invention has good fluidity, firm welding, and is easy to weld. The obtained cloisonné filigree is precisely positioned, wear-resistant, high in hardness, and never fades; it adopts the bright white glaze process and twice-grinded blue to obtain The handicrafts are better in color, look new with time, never rust, have high collection value, and can satisfy people's high-level artistic enjoyment.

Owner:赵爱民

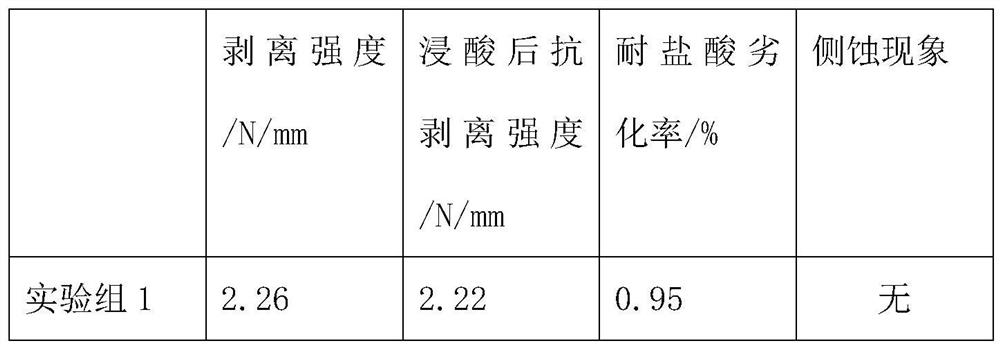

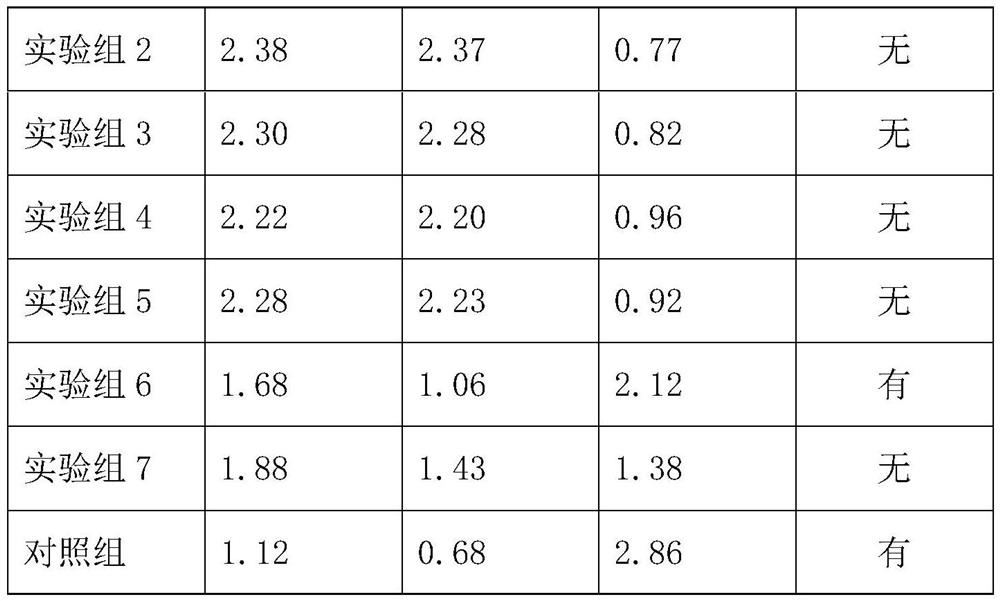

High-corrosion-resistance flexible copper-clad plate and preparation method thereof

ActiveCN113692111AImprove corrosion resistanceImprove wear resistancePrinted circuit detailsFlexible printed circuitsPolyethylene glycolCopper foil

The invention discloses a high-corrosion-resistance flexible copper-clad plate, and particularly relates to the technical field of flexible copper-clad plates. The high-corrosion-resistance flexible copper-clad plate comprises an insulating base material and a copper foil layer, a transition layer is arranged between the insulating base material and the copper foil layer, a corrosion-resistant layer is arranged on the outer side of the copper foil layer, the transition layer is an active electrode material layer, and the corrosion-resistant layer comprises a zinc coating and a nano coating. The zinc coating and the nano coating are arranged on the outer side of the copper foil layer, the auxiliaries are added during zinc plating on the outer side of the copper foil layer, and the auxiliaries comprise sodium dodecyl benzene sulfonate, polyethylene glycol, rare earth salt and arsenic trioxide, so that the corrosion resistance of the zinc coating can be improved while the zinc coating is formed, the crystal form of the zinc coating can be changed, the surface of the zinc coating is flat and uniform, crystals are fine and compact, the corrosion resistance of the zinc coating is improved, the corrosion resistance of the flexible copper-clad plate is improved, meanwhile, the wear resistance of the flexible copper-clad plate can be improved through the nano coating, and therefore the service life of the flexible copper-clad plate is prolonged.

Owner:江苏耀鸿电子有限公司

Smelting flue gas purification process

PendingCN113842771AEfficient removalEffective absorptionGas treatmentDispersed particle filtrationFlue gasDust control

Owner:CHENGDU INTERMENT TECH

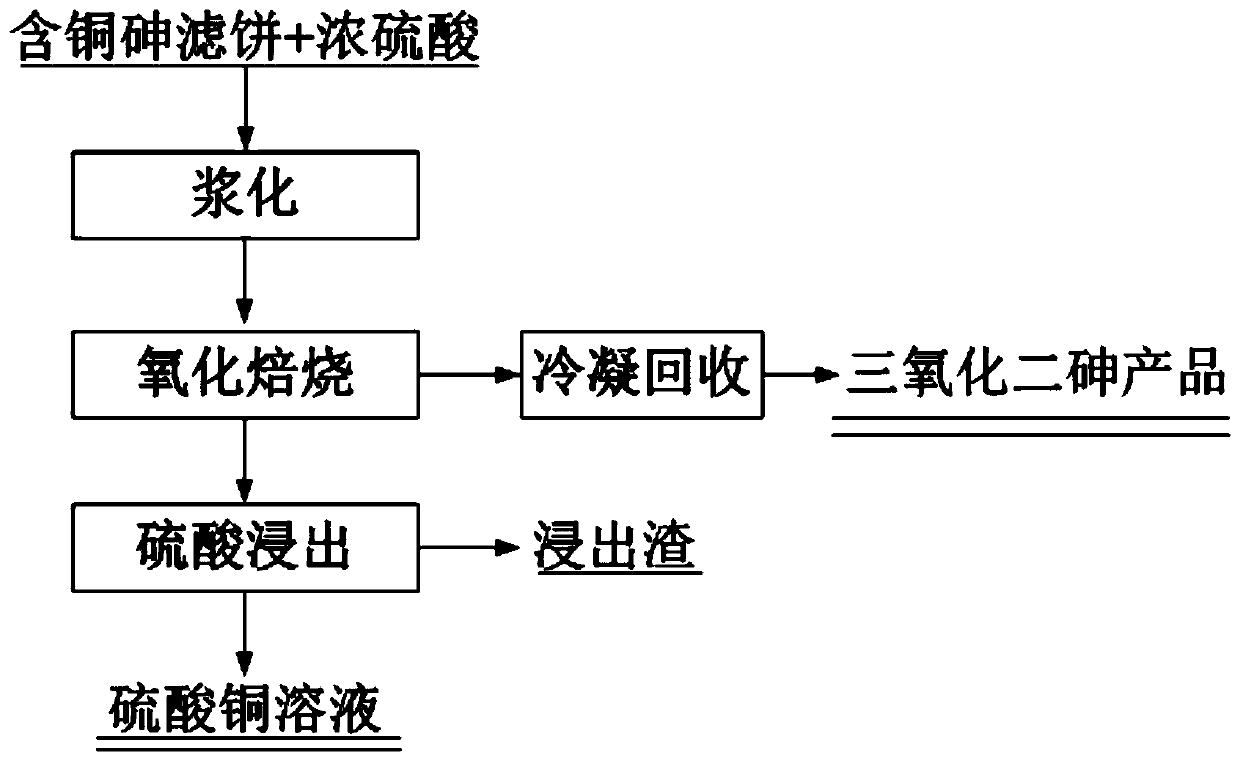

Method for treating copper and arsenic containing filter

InactiveCN111363924AEfficient removalAchieve recyclingArsenic oxides/hydroxides/oxyacidsProcess efficiency improvementSlagSoot

The invention discloses a method for treating a copper and arsenic containing filter cake. The method comprises the following steps of selecting the copper and arsenic containing filter cake, performing slurrying on the copper and arsenic containing filter cake and concentrated sulfuric acid, performing oxidizing roasting on the slurried copper and arsenic containing filter cake, carrying out condensation recovery on soot generated in oxidizing roasting, during the oxidizing roasting process, volatilizing arsenic in the copper and arsenic containing filter cake into the soot in the form of arsenic trioxide, that is, obtaining an arsenic trioxide product after condensation recovery, and obtaining roasted slag after oxidizing roasting; and performing sulfuric acid leaching treatment on the obtained roasted slag with a sulfuric acid solution, leaching copper in the roasted slag in the solution in a form of copper sulfate during the sulfuric acid leaching treatment process, and completingthe sulfuric acid leaching treatment to obtain leaching residue and a copper sulfate solution, that is, completing the treatment of the copper and arsenic containing filter. The method is simple to operate and convenient to implement, can realize the efficient removal and comprehensive recycling of the arsenic in the copper and arsenic containing filter cake, does not cause secondary pollution tothe environment, and is beneficial to popularization and application.

Owner:TONGREN UNIV

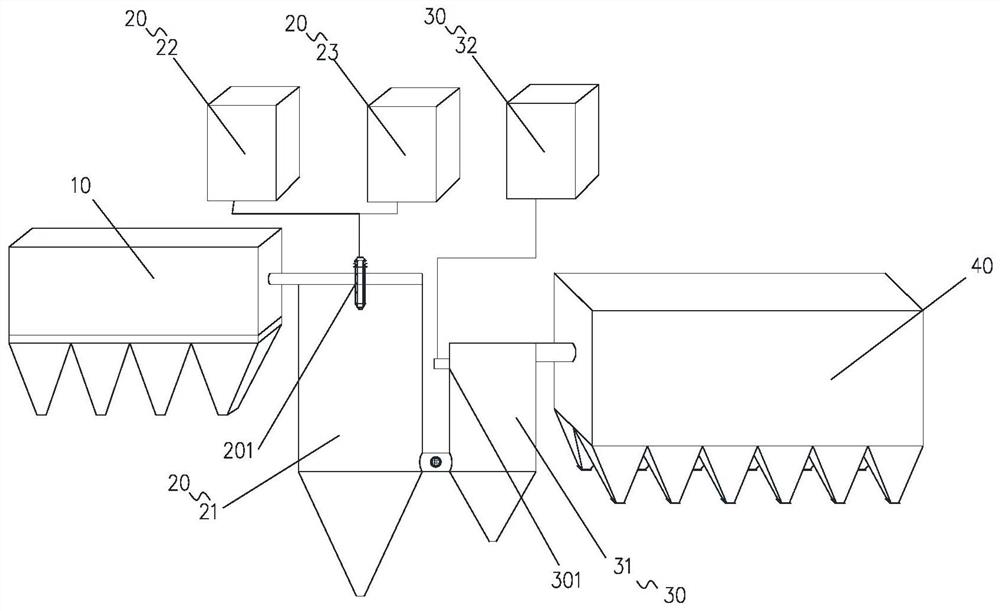

Arsenic collecting system for dioxin-containing smelting flue gas and method thereof

InactiveCN113731048APrevent respawnLower acid dew pointGas treatmentDispersed particle filtrationFlue gasNonferrous metal

The invention provides an arsenic collecting system for dioxin-containing smelting flue gas and a method thereof. The system comprises a first dust collection unit, a quenching deacidification unit, a sedimentation unit and a second dust collection unit. Through layer-by-layer cooperative utilization of the systems, the yield of arsenic trioxide is 95-98%, the yield of non-ferrous metal dust is greater than 98%, and the content of dioxin substances in finally discharged flue gas is below 0.5 ngTEQ / Nm<3>.

Owner:CHINA ENFI ENGINEERING CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com