Process for efficiently treating copper smelting smoke dust

A technology of copper smelting and dust, which is applied in the field of hazardous dust treatment, can solve the problems of difficult disposal of arsenic-containing solid waste, low lead content in copper smelting dust, and low quality of arsenic trioxide, so as to realize effective recycling of waste and guarantee occupational Healthy, high recovery rate of valuable metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

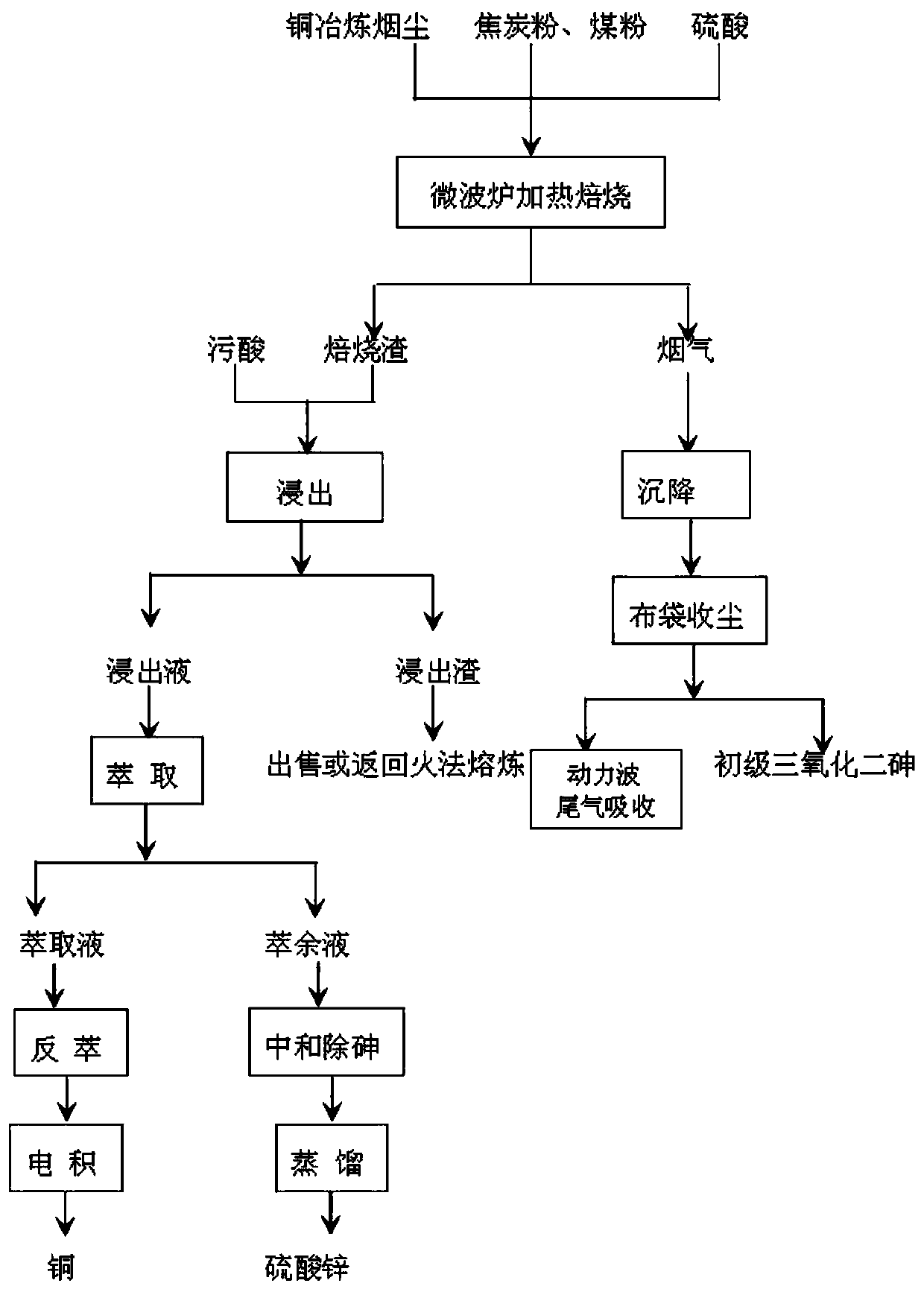

Image

Examples

Embodiment 1

[0034] A process for efficiently treating copper smelting smoke and dust. The copper smelting smoke and dust is the smoke and dust generated by electric dust collection during the copper smelting process. The smoke and dust components are as follows:

[0035] Numbering sn As Pb Fe Cu Zn raw material 1 2.64 13.86 11.70 4.01 1.041 12.51

[0036] The processing steps are as follows:

[0037] (1) Take 10 kg of copper smelting dust, 0.5 kg of coke powder, and 1 kg of sulfuric acid, mix them evenly, and slowly feed them into the special microwave oven for smelting and volatilization through screw feeding. The temperature is controlled at about 550 ° C, and the material stays in the furnace for 3 hours. Negative pressure in the furnace is -20~-10Pa, microwave roasting is carried out, and the arsenic trioxide product is collected in the settling chamber of the microwave oven. The purity of the obtained product is 92.3%.

[0038] (2) Take the roast...

Embodiment 2

[0042] A process for efficiently treating copper smelting smoke and dust. The copper smelting smoke and dust is the smoke and dust generated by electric dust collection during the copper smelting process. The smoke and dust components are as follows:

[0043] The processing steps are as follows:

[0044] Numbering sn As Pb Fe Cu Zn raw material 2 6.90 14.89 10.31 1.40 2.65 7.52

[0045] (1) Take 10 kg of copper smelting dust, 3 kg of coke powder and coal powder, and 2 kg of sulfuric acid, mix them evenly, and slowly enter the special microwave oven for smelting and volatilization through screw feeding, control the heating temperature to 500 ° C, and the residence time of the materials in the furnace for 3 hour, the negative pressure in the furnace is -20~-10Pa, microwave roasting is carried out, the arsenic trioxide product is collected in the settling chamber, the product purity is 94.1%, and the flue gas is absorbed by sodium hydroxide alka...

Embodiment 3

[0050] A process for efficiently treating copper smelting smoke and dust. The copper smelting smoke and dust is the smoke and dust generated by electric dust collection during the copper smelting process. The smoke and dust components are as follows:

[0051] Numbering sn As Pb Fe Cu Zn raw material 2 4.67 16.32 14.66 0.814 1.97 8.46

[0052] The treatment process is as follows:

[0053] (1) Take 10 kg of copper smelting dust, 5 kg of coal powder, and 4 kg of sulfuric acid and mix them evenly, then slowly enter the special microwave oven for smelting volatilization through screw feeding, control the microwave heating temperature at 700 ° C, and keep the materials in the furnace for 2 hours. The negative pressure in the furnace is -20~-10Pa, microwave roasting is carried out, and the arsenic trioxide product is collected in the settling chamber, and the product purity is 95.4%.

[0054] (2) Take the roasted slag obtained in step (1) in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com