Treatment method and device for incineration arsenic-containing flue gas

A treatment method and flue gas technology, applied in the field of environmental engineering, can solve the problems of secondary pollution of mud and arsenic, large amount of sewage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

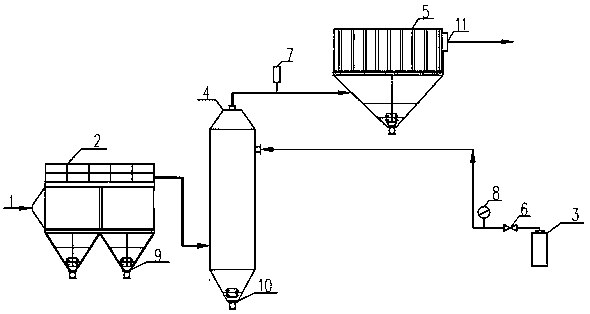

Embodiment 1

[0027] The centipede grass used in this embodiment is taken from Huanjiang County, Guangxi. The upper part of the centipede grass is taken, dried in a constant temperature box at 70°C, pulverized with a pulverizer, and finally passed through a 0.18mm sieve to obtain an experimental sample, and the sample is weighed in an incinerator incineration, the temperature is 620 ° C, the atmosphere is air; and the rate of 400mL / min passes through figure 1 The shown device includes a ceramic tube dust collector 2, a liquid nitrogen bottle 3, a mixing chamber 4, and an electrostatic precipitator 5; the ceramic tube dust collector is provided with an air inlet 1, and the bottom of the ceramic tube dust collector is provided with an ash discharge port 9 , the outlet of the ceramic tube dust collector communicates with the bottom of the mixing chamber 4, the liquid nitrogen bottle 3 communicates with the liquid nitrogen inlet on the upper part of the mixing chamber 4 through the valve 6, and ...

Embodiment 2

[0034]The centipede grass used in this embodiment is taken from Huanjiang County, Guangxi. The upper part of the centipede grass is taken, dried in a constant temperature box at 70°C, pulverized with a pulverizer, and finally passed through a 0.18mm sieve to obtain an experimental sample, and the sample is weighed in an incinerator Incineration, the combustion temperature is 610 ° C, the atmosphere is air, and the rate of 300mL / min passes through figure 1 Device, device structure is the same as embodiment 1;

[0035] The treatment steps of incineration flue gas containing arsenic are as follows:

[0036] (1) The incineration arsenic-containing flue gas enters the ceramic tube dust collector 2 from the air inlet 1, and after the solids such as ash in the flue gas are intercepted, the ash will enter the bottom of the ceramic tube dust collector 2 and be recovered through the ash discharge port 9 , the flue gas enters the mixing chamber 4 after dedusting;

[0037] (2) After the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com