Method of separating arsenic from copper slag through cooperation of high-arsenic material

A technology of copper slag and materials, which is applied in the field of separating arsenic from copper slag with high-arsenic materials, can solve the problem of difficult separation of arsenic and copper slag, and achieve the effect of reducing high temperature viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

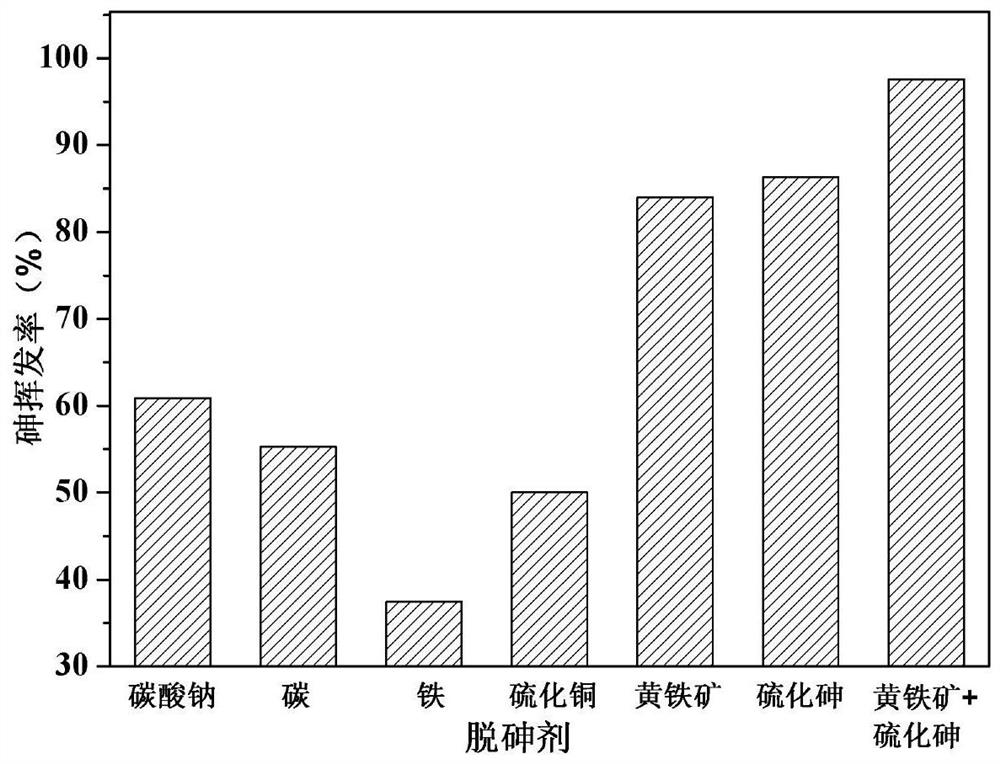

[0028] In this example, the copper slag after smelting in a copper smelter in Shandong is selected. The main element composition is shown in Table 1. Sodium carbonate, carbon, iron, copper sulfide, pyrite, arsenic sulfide slag, and pyrite combined with arsenic sulfide are selected respectively. Slag (mass ratio is 7:3) is used as arsenic removal agent, and the specific implementation steps are as follows:

[0029] Table 1 Composition of main elements in smelting copper slag of a copper smelter in Shandong (%)

[0030] element Fe Si As Cu Pb Ca S Zn content(%) 46.40 13.13 1.50 8.31 0.74 2.89 2.27 3.49

[0031] (1) Take copper smelting high-arsenic smelting slag and arsenic-removing agent respectively, dry them at low temperature, and crush them to a particle size less than 2mm respectively, and mix the copper slag and the arsenic-removing agent evenly according to the addition amount of the arsenic-removing agent to obtain a mixture ma...

Embodiment 2

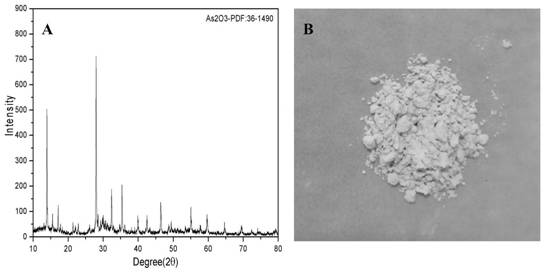

[0035] In this example, the copper slag after smelting in a copper smelter in Shandong was selected, and its main element composition is the same as in Example 1. A mixture of pyrite and arsenic sulfide slag (mass ratio 7:3) was selected as the arsenic removal agent, and the arsenic sulfide The main element composition of the slag is shown in Table 2, and the specific implementation steps are as follows:

[0036] Table 2 Composition of main elements of arsenic sulfide slag (%)

[0037] element Fe Si As Cu Pb Ca S content(%) 0.25 0.12 43.67 1.58 0.12 0.33 39

[0038] (1) Select the mixture of pyrite and arsenic sulfide slag as the arsenic removal agent, take the high-arsenic smelting slag from copper smelting and the arsenic removal agent respectively, dry them at low temperature, and crush them until the particle size is less than 2mm, according to the amount of the arsenic removal agent added 10wt%, wherein the addition of pyrite is 7wt...

Embodiment 3

[0042] In this example, the copper slag after smelting in a copper smelter in Shandong was selected, and its main element composition is the same as in Example 1. A mixture of pyrite and arsenic sulfide slag (mass ratio 7:3) was selected as the arsenic removal agent, and the arsenic sulfide The main element composition of the slag is shown in Table 2, and the specific implementation steps are as follows:

[0043] (1) Select the mixture of pyrite and arsenic sulfide slag as the arsenic removal agent, take the high-arsenic smelting slag from copper smelting and the arsenic removal agent respectively, dry them at low temperature, and crush them until the particle size is less than 2mm, according to the amount of the arsenic removal agent added 10wt%, wherein the addition of pyrite is 7wt%, the addition of arsenic sulfide slag is 3wt%, and then the copper slag and the arsenic removal agent are evenly mixed to obtain a mixture;

[0044] (2) Weigh 40 g of the above-mentioned mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com