Method and device for recycling arsenic from high arsenic smoke

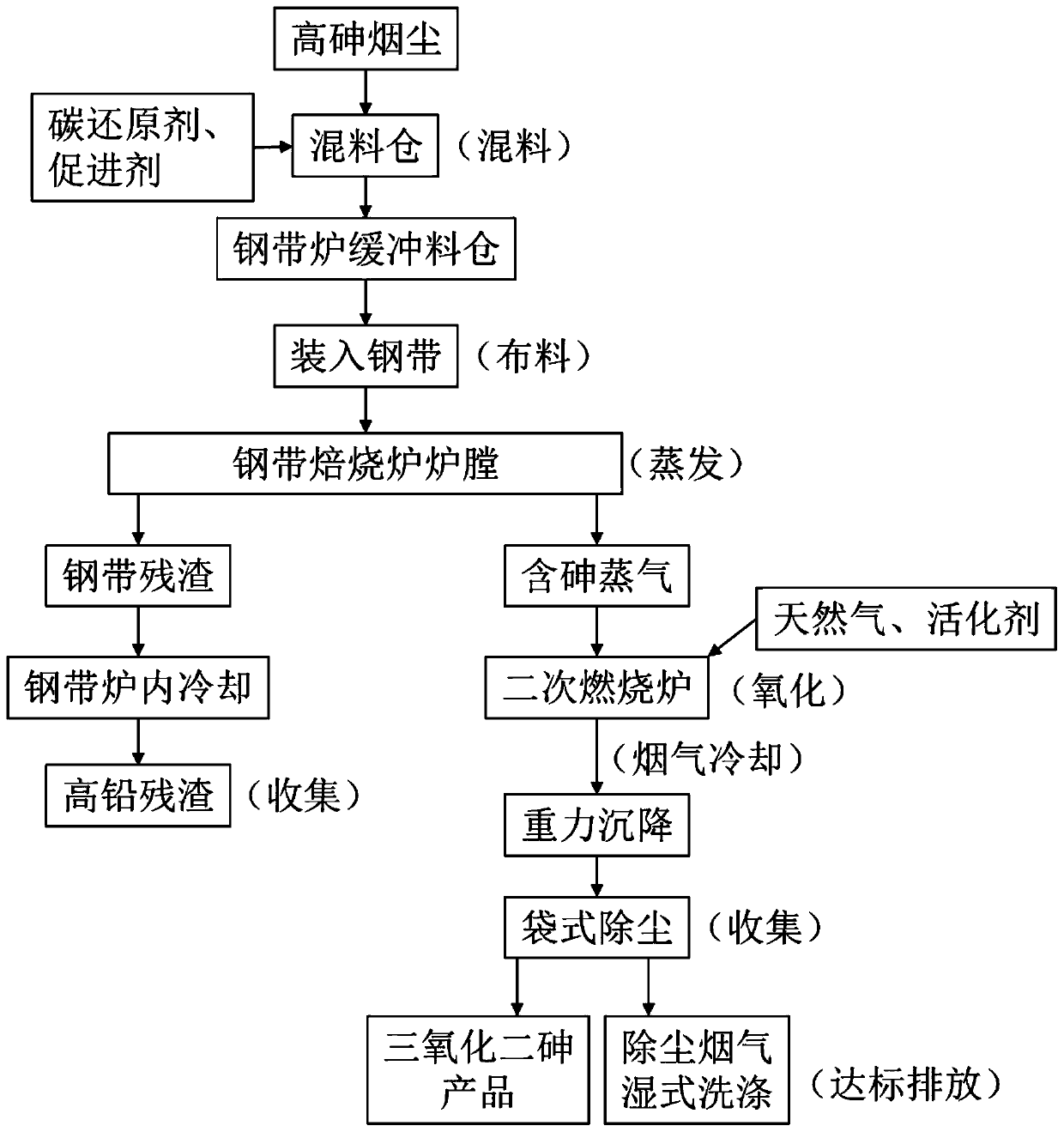

A technology for arsenic fume and recovery of arsenic, which is applied in the directions of combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of high arsenic hazard, difficult separation, and can not achieve the separation of arsenic trioxide, etc., and achieves less impurity content and improved purity. , the effect of low environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

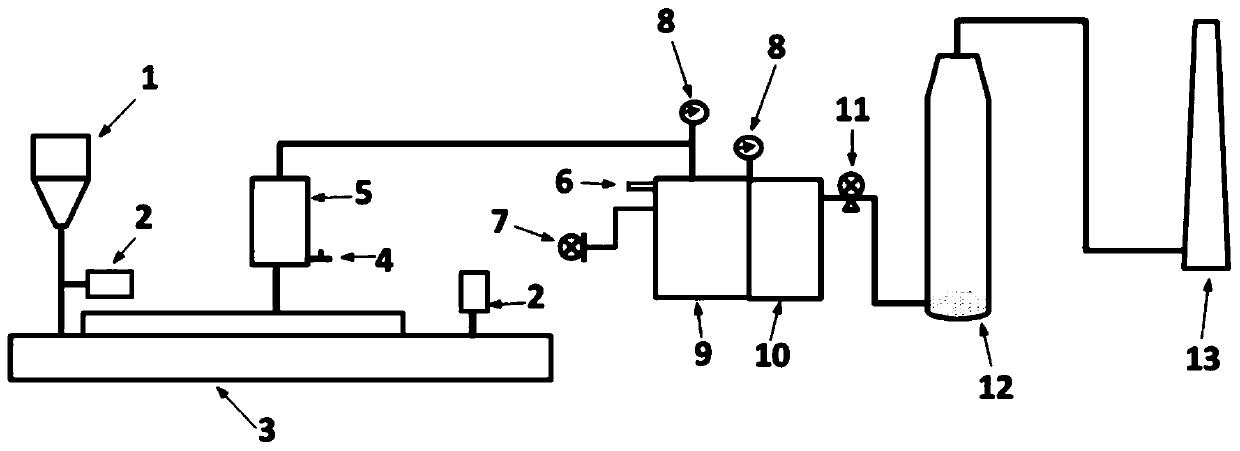

[0055] This embodiment provides a device for recovering arsenic from high-arsenic smoke and dust. figure 2 Shown: It includes a roasting furnace 3, a combustion furnace 5, a settling chamber 9, a dust collector 10, a spray tower 12, and an external chimney 13 which are connected in sequence; among them, the roasting furnace 3 includes a furnace and the material containing high arsenic smoke and dust is introduced into the furnace. In the continuous feeding device for internal roasting, a mixing bin 1 is arranged above the continuous feeding device.

[0056] The continuous feeding device includes a steel belt for conveying materials containing high arsenic smoke and dust, and a sealing cover located above the steel belt. The sealing cover is filled with protective gas. The mixing bin 1 includes a batching bin located at the upper part and a distributor located at the lower part Among them, the distributor is filled with protective gas, and the protective gas is nitrogen, which is ...

Embodiment 2

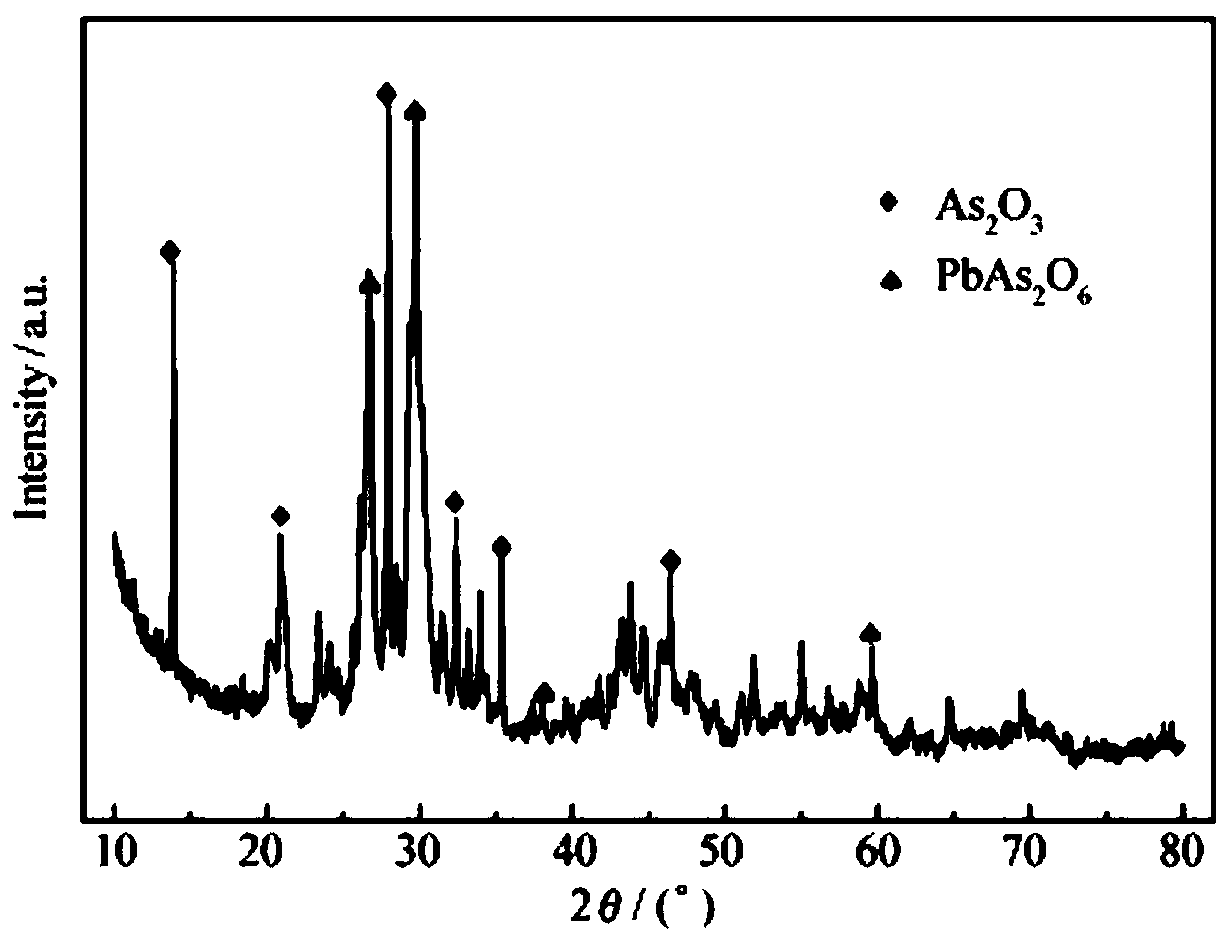

[0060] The main components of the high arsenic smoke and dust treated in this embodiment are calculated as mass percentage: As30.25%, Pb28.45, Cu3.02%, Zn4.21%, S4.23%, Sb1.46% and Fe26.35% , The phase XRD data such as image 3 Shown.

[0061] The method for recovering arsenic from high-arsenic fumes in this embodiment adopts the device in Example 1 for recovery and includes the following steps:

[0062] Mix 500kg of the above-mentioned smoke dust with 50kg of activated carbon powder (based on 10% of the smoke and dust mass, particle size ≤0.15mm), 2.5kg of limestone (based on the mass of smoke and dust 0.5%) in the mixing bin, then enter the distributor, and protect it with nitrogen. The distributor makes the material evenly distributed on the steel belt of the steel belt baking furnace. With the operation of the steel belt, the high-arsenic fume mixture material enters the well-sealed steel belt electric heating and evaporation furnace furnace, fills the furnace chamber with nit...

Embodiment 3

[0065] The main components of the high arsenic smoke and dust treated in this embodiment are as follows: As25.46%, Pb24.35%, Cu3.14%, Zn3.18%, S2.06%, Sb0.95% and Fe26.26 %.

[0066] The method for recovering arsenic from high-arsenic fumes in this embodiment adopts the device in Example 1 for recovery and includes the following steps:

[0067] Mix 500kg of the above-mentioned smoke dust with 60kg of biomass charcoal powder (calculated by the mass of smoke and dust, particle size ≤0.10mm), 1.5kg of lime (calculated by the mass of smoke and dust 0.3%) in the mixing bin, then enter the distributor and pass nitrogen Sealing and protecting the distributor makes the material evenly distributed on the steel belt of the steel belt baking furnace. With the running of the steel belt, the high-arsenic fume mixture material enters the well-sealed steel belt electric heating evaporating furnace hearth, fills the hearth with nitrogen, and maintains the pressure in the furnace at -0.6kPa. The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com