Lead anode mud melting high temperature furnace gas grading temperature control dust collection purifying technology

A technology for smelting and purifying lead anode slime, which is applied in the fields of arsenic compounds, inorganic chemistry, separation methods, etc., and can solve problems such as processing troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

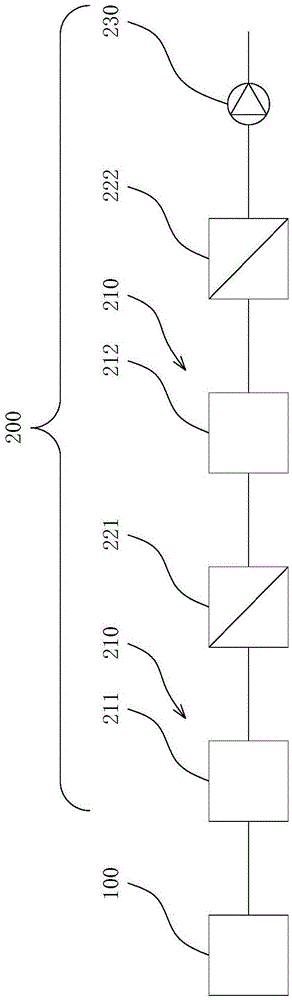

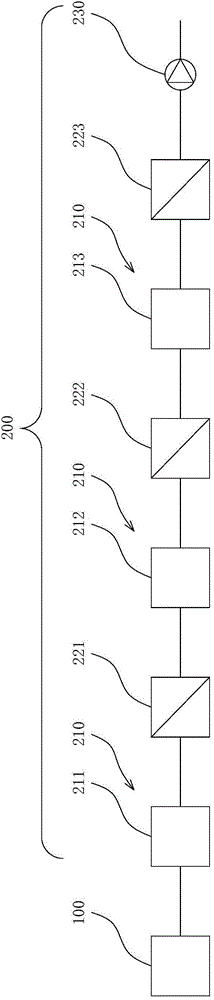

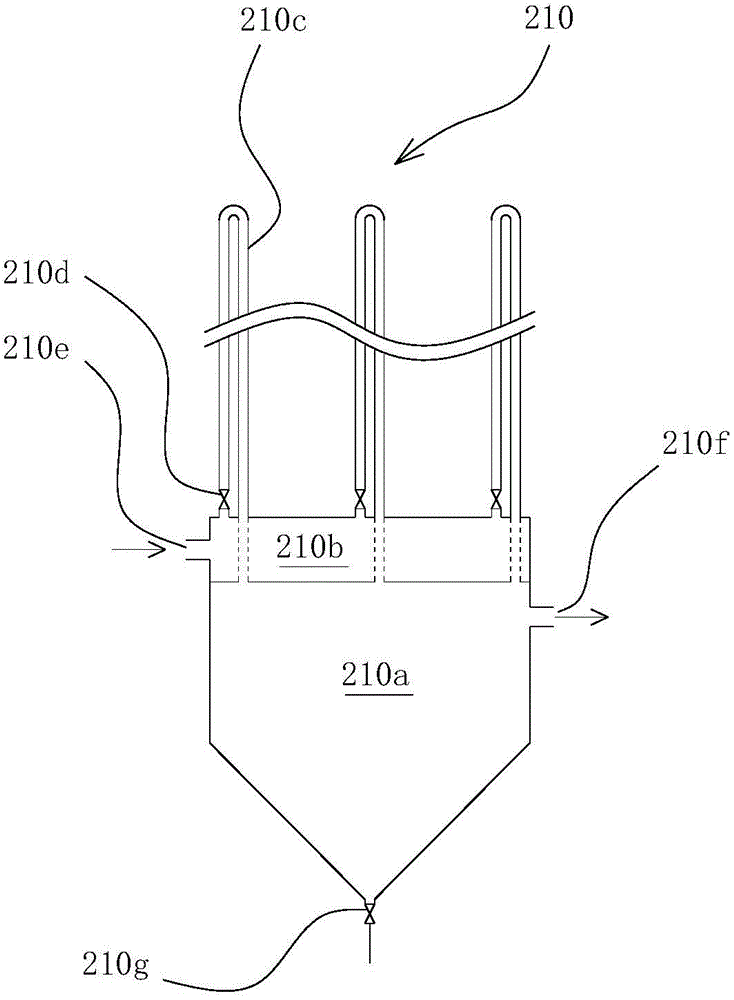

[0038] figure 1 Shown is a process and equipment for smelting high-temperature furnace gas of lead anode slime to collect and purify dust by classification and temperature control. The first-stage gas filter unit 221, the second-stage temperature-controlled cooling unit 212, the second-stage gas filter unit 222, and the power device 230, the power device 230 drives the furnace gas generated by the industrial furnace 100 to pass through the first-stage temperature-controlled cooling unit 211 in sequence , the first-stage gas filter unit 221 , the second-stage temperature-controlled cooling unit 212 and the second-stage gas filter unit 222 . The steps of adopting the above-mentioned equipment for smelting high-temperature furnace gas of lead anode slime to collect dust by classifying temperature control include: 1) introducing the furnace gas for smelting lead anode slime with a temperature of 600-900°C produced by the industrial kiln 100 into the above-mentioned equipment, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com