A method for recovering copper and arsenic from copper smelting white smoke leach liquor and arsenic filter cake

A technology of white smoke and leaching solution, applied in the field of comprehensive resource utilization, can solve the problems of high production cost and low copper precipitation rate, achieve high recovery rate, shorten production process, save time and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

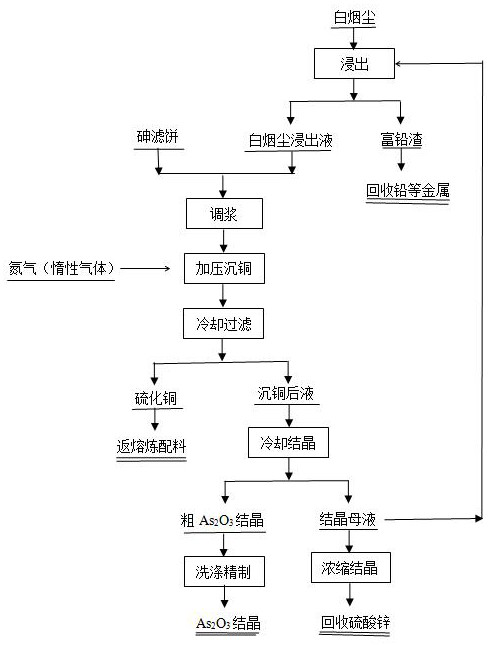

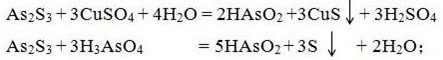

Method used

Image

Examples

Embodiment 1

[0047] 1. Pressurized sinking copper

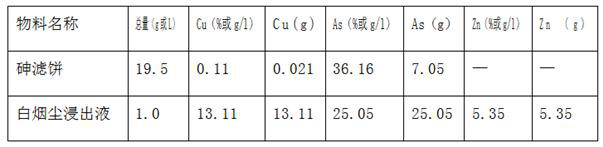

[0048] Under the conditions of reaction temperature 102°C, reaction time 2h, nitrogen (or inert gas) pressure 0.3MPa, acidity of white soot leaching solution 30g / L, arsenic filter cake amount 0.7 times the theoretical amount, the copper precipitation reaction was carried out, and the reaction was carried out in 2L Carried out in an autoclave, the composition of the arsenic filter cake and white smoke leach solution before the reaction is shown in the following table:

[0049]

[0050] 2. Cooling and filtering

[0051] After the reaction is completed, filter after pressure relief and cooling to obtain copper-precipitated liquid and copper sulfide. The relevant components are shown in the following table:

[0052]

[0053] 3. Cooling crystallization

[0054] The concentration of As in the liquid after copper precipitation is low, and it has not yet reached saturation, so it cannot crystallize during the cooling process, and returns ...

Embodiment 2

[0056] 1. Pressure sinking copper

[0057] Under the conditions of reaction temperature 115°C, reaction time 2h, nitrogen (or inert gas) pressure 0.3MPa, acidity of white soot leaching solution 80g / L, arsenic filter cake amount 1.05 times the theoretical amount, the copper precipitation reaction was carried out, and the reaction was carried out in 2L Carried out in an autoclave, the composition of the arsenic filter cake and white smoke leach solution before the reaction is shown in the following table:

[0058]

[0059] 2. Cooling filter

[0060] After the reaction is completed, after pressure relief and cooling, filter to obtain the copper-precipitated liquid and copper sulfide. The relevant components are shown in the following table:

[0061]

[0062] 3. Cooling and crystallization

[0063] The filtered copper-precipitated liquid continues to be stirred and cooled to room temperature to obtain crude crystals of diarsenic trioxide and crystallization mother liquor, cr...

Embodiment 3

[0071] 1. Pressurized sinking copper

[0072] Under the conditions of reaction temperature 125°C, reaction time 2h, nitrogen (or inert gas) pressure 0.3MPa, acidity of white soot leaching solution 100g / L, arsenic filter cake amount 0.7 times the theoretical amount, the copper precipitation reaction was carried out, and the reaction was carried out in 2L Carried out in an autoclave, the composition of the arsenic filter cake and white smoke leach solution before the reaction is shown in the following table:

[0073]

[0074] 2. Cooling and filtering

[0075]

[0076] 3. Cooling crystallization

[0077] The filtered copper-precipitated liquid continues to be stirred and cooled to room temperature to obtain crude crystals of diarsenic trioxide and crystallization mother liquor, crystallization mother liquor

[0078] Return to the leaching of white smoke, the composition of the mother liquor is shown in the following table:

[0079]

[0080] 4. Refined arsenic trioxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com