Method for preparing arsenic trioxide from black copper sludge

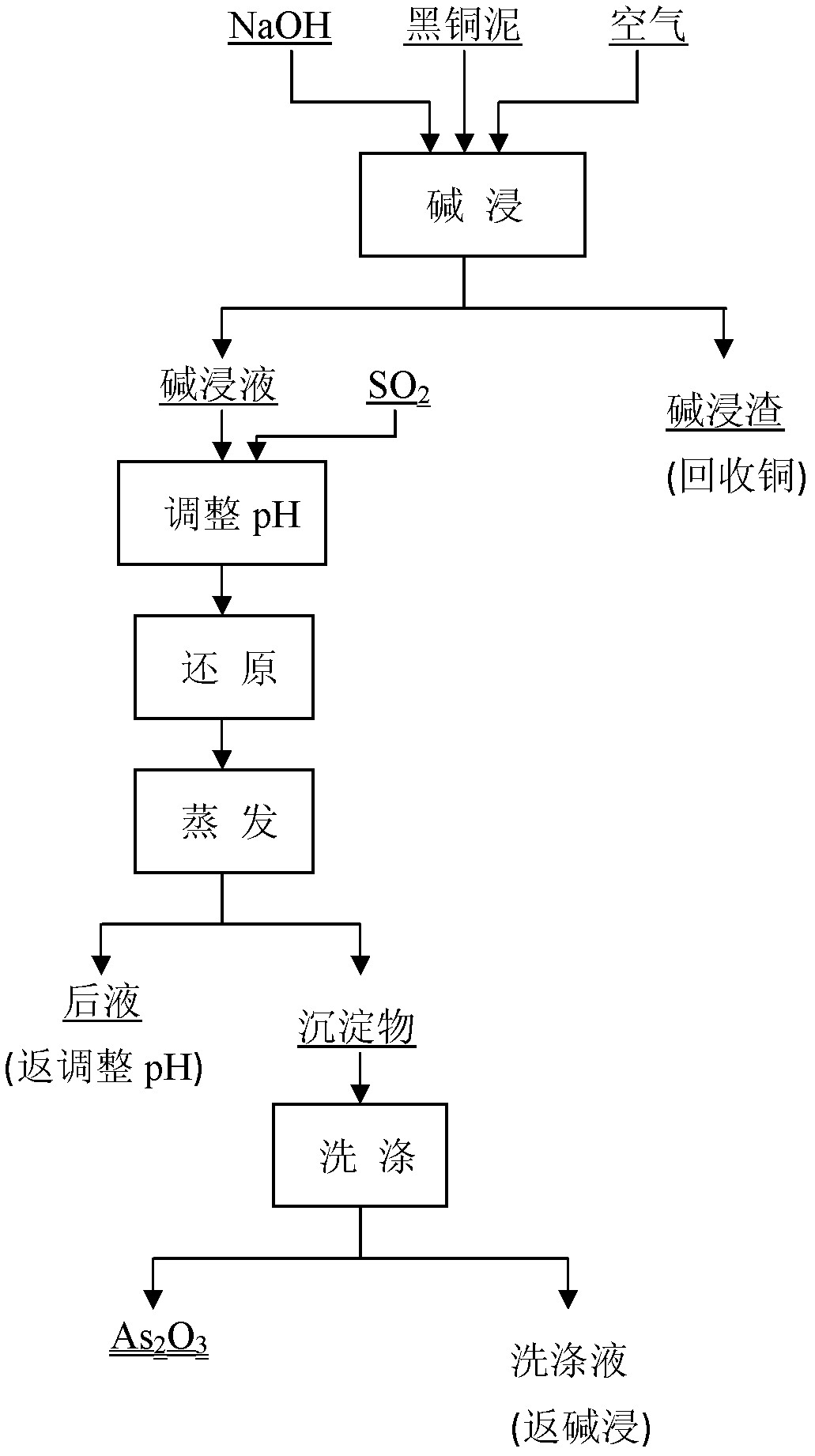

A technology of arsenic trioxide and black copper mud, applied in chemical instruments and methods, arsenic compounds, inorganic chemistry, etc., can solve the problems of long process flow, high cost, secondary pollution of solid waste, etc. of arsenic trioxide, so as to avoid secondary pollution. , The effect of low production cost and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take black copper mud (content: Cu41.92%, As22.40%, Sb6.60%, Fe0.10%) 30g, according to the liquid-solid ratio is 8:1, the concentration of sodium hydroxide solution is 2mol / L, prepare After the solution is finished, when the temperature rises to 95°C, black copper mud is added to the solution, and air is introduced to control the air volume to 0.8m 3 / h, stirred and leached for 6 hours, added sulfuric acid to the filtrate after filtration to adjust pH=-1, passed SO into the solution 2 After reacting for 2 hours, the solution was evaporated, concentrated and crystallized to obtain a precipitate, which was washed and dried to obtain the arsenic trioxide product. The purity of arsenic trioxide is 95.78%, reaching the product quality standard of YS-T99-1997.

Embodiment 2

[0029] Get black copper mud (content is: Cu41.92%, As22.40%, Sb6.60%, Fe0.10%) 30g, be 8: 1 by liquid-solid ratio, sodium hydroxide solution concentration is 1.5mol / L, Prepare the solution, and when the temperature rises to 85°C, add black copper mud to the solution, and let air in, and control the air volume to 0.6m 3 / h, stirred and leached for 8 hours, added sulfuric acid to the filtrate after filtration to adjust pH=0, passed SO into the solution 2 After reacting for 1 hour, the solution was evaporated, concentrated and crystallized to obtain a precipitate, which was washed and dried to obtain the arsenic trioxide product. The purity of arsenic trioxide is 96.23%, reaching the product quality standard of YS-T99-1997.

Embodiment 3

[0031] Get black copper mud (content is: Cu41.92%, As22.40%, Sb6.60%, Fe0.10%) 30g, be 8: 1 by liquid-solid ratio, sodium hydroxide solution concentration is 1.5mol / L, Prepare the solution, and when the temperature rises to 90°C, add black copper mud to the solution, and let air in, and control the air volume to 0.6m 3 / h, stirred and leached for 8 hours, added sulfuric acid to the filtrate after filtration to adjust pH=0, passed SO into the solution 2 After reacting for 2 hours, the solution was evaporated, concentrated and crystallized to obtain a precipitate, which was washed and dried to obtain the arsenic trioxide product. The purity of arsenic trioxide is 97.51%, reaching the product quality standard of YS-T99-1997.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com