Method for controlling dioxin in fly ash washing process through sintering treatment

A control method and sintering treatment technology, applied in the field of waste incineration fly ash treatment, can solve the problems of high chlorine content, affecting the quality of sintered ore, equipment corrosion, etc., to reduce secondary generation, prevent secondary generation, and facilitate centralized degradation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

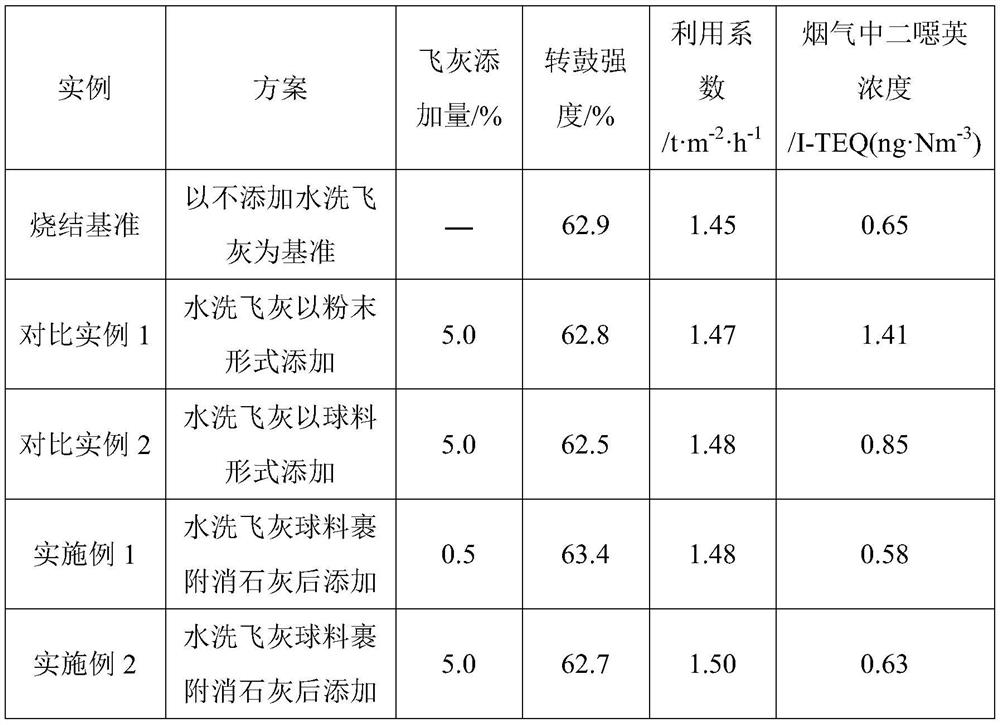

Embodiment 1

[0041] The grate furnace garbage incineration fly ash was washed to obtain washed fly ash with a Cl content of 0.7%, and the washed fly ash was made into 5mm pellets, and the CaO / SiO in the washed fly ash pellets 2 The mass ratio is 2.5. Before drying, wrap a layer of slaked lime (the activity of quicklime is 270ml) with a thickness of 1 mm, and dry at 100°C for 2 hours at a low temperature until the water content is 5%. 60% iron ore, 4% coke powder (-0.5mm, 0.5~3mm and 3~5mm accounted for 20%, 60%, 20% respectively), 11% limestone, 25% returned ore were mixed to make When the granulation progresses to the 5th minute, evenly add water-washed fly ash pellets coated with quicklime along the horizontal axis of the cylinder. The water-washed fly ash pellets are fully mixed with the sintering raw materials. Use a nine-roll distributor (the gap between the 5#~9# rollers is controlled to be 5~8mm) to spread the obtained sintered mixture with water-washed fly ash pellets on the midd...

Embodiment 2

[0043] The grate furnace waste incineration fly ash was washed with water to obtain washed fly ash with a Cl content of 1.0%, and the washed fly ash was made into 8mm pellets, and the CaO / SiO in the washed fly ash pellets 2 The mass ratio is 3.0. Before drying, wrap a layer of 0.5mm thick slaked lime (the activity of quicklime is 250ml), and dry at 80°C for 3 hours at a low temperature until the water content is 9%. 65% iron ore, 4.5% coke powder (-0.5mm, 0.5~3mm and 3~5mm accounted for 20%, 60%, 20% respectively), 10.5% limestone, 20% returned ore and other sintering raw materials Mixing and granulation. When the granulation reaches the 3rd minute, add washed fly ash pellets coated with slaked lime evenly along the horizontal axis of the cylinder. The amount of washed fly ash pellets added is 5.0% of the sintering raw materials, and continue to granulate for 1 minute. , so that the water-washed fly ash pellets are fully mixed with the sintering raw materials. Use a nine-rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size range | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com