A gas hydrate decomposition and reaction liquid recovery device

A gas hydrate and recovery device technology, which is applied in the direction of gas fuel, separation method, and dispersed particle separation, etc., can solve the problems of insufficient use of gas waste heat, energy waste, etc., achieve smooth flow of gas phase, improve decomposition efficiency, and reduce gas loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

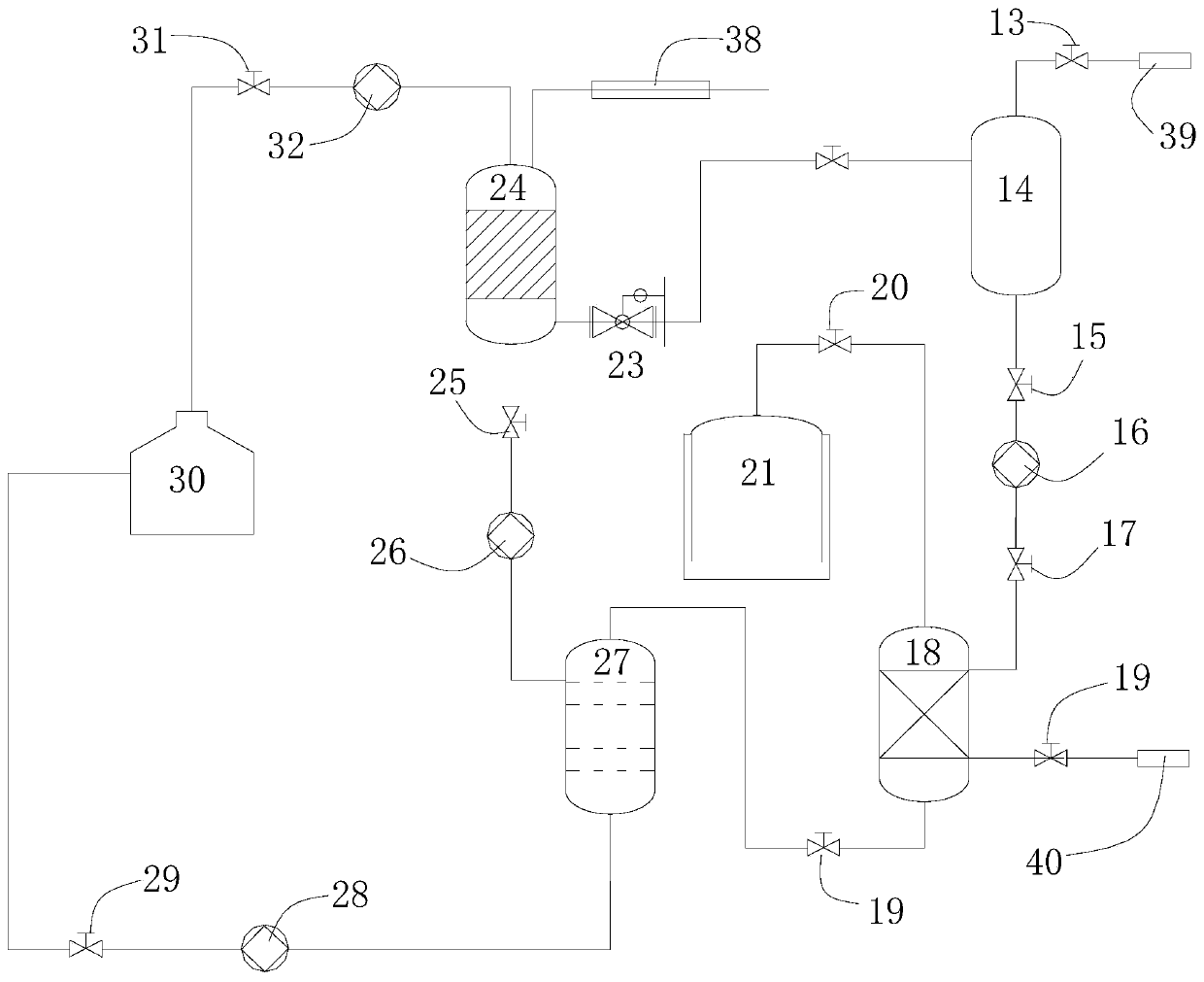

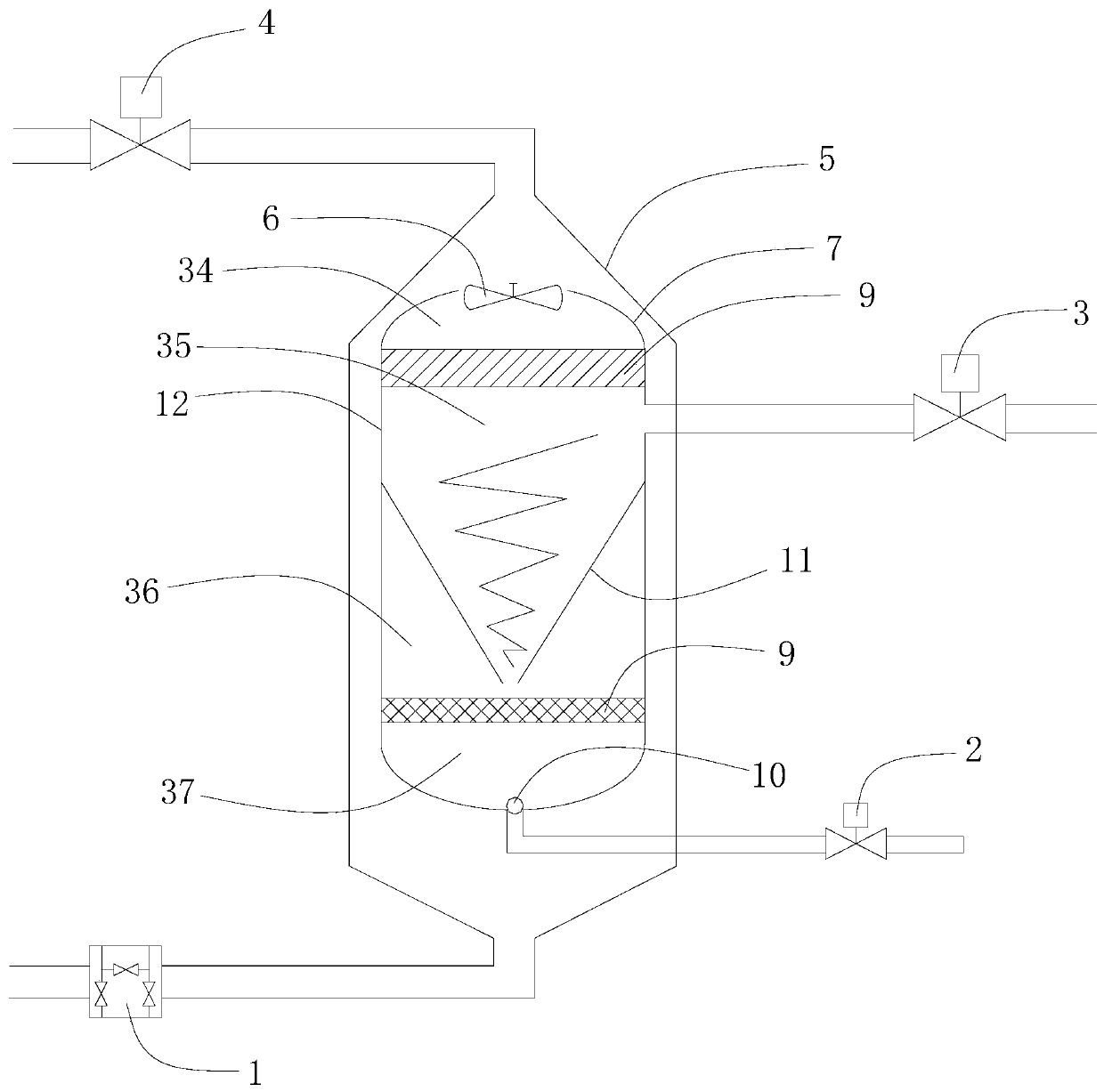

[0025] refer to figure 1 and figure 2, is a gas hydrate decomposition and reaction liquid recovery device, including a three-phase separator 14, a gas hydrate decomposition unit 18, a carbon dioxide collection tank 21, an absorption liquid regeneration unit 27, a chemical absorption tower 24, and an absorption tank containing ethanolamine solution Liquid storage tank 30, slurry pump 16, back pressure valve 23, first corrosion-resistant pump 26, second corrosion-resistant pump 28, third corrosion-resistant pump 32; in this embodiment, the structures are connected by pipelines, and the pipelines Add some stop valves and one-way air valves according to actual needs. The IGCC synthesis gas and its slurry separated by the hydrate method are sequentially input from the hydrate slurry inlet 39 and the input end of the first stop valve 13, and the output end of the first stop valve 13 is connected to the input end of the three-phase separator 14; The first output end of the three-p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com