Belgian type white beer and making method thereof

A production method and technology of white beer, which is applied in the field of beer brewing, can solve the problems of low acetic acid content, high foam retention, and low foam retention of acetic acid content, and achieve the goals of reducing content, improving foam retention, and reducing secondary production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A Belgian-style white beer obtained by:

[0027] 1) Light-colored barley malt and wheat malt are selected as raw materials, and the weight ratio of light-colored barley malt and wheat malt is 6:4; wherein, the protein content of light-colored barley malt is 9.0% to 12.0%, and the foam protein content is ≥ 4.0g / kg; the protein content of wheat malt is 11.5% to 14.5%, and the foam protein content is ≥7.5g / kg. Crush the ingredients and set aside.

[0028] 2) Put the pulverized raw materials into the mash pot, add water, saccharify with gradient temperature increase, and filter the wort; the gradient temperature increase is carried out according to the following heating program: first, the temperature is raised to 50°C, kept for 30 minutes, then heated to 62°C, kept for 50 minutes, and continued to heat up Heat to 68°C, hold for 15 minutes, raise the temperature to 72°C, hold for 30 minutes, and finally raise the temperature to 78°C.

[0029] 3) The filtered wort was boi...

experiment example 1

[0049] The foam retention of test embodiment and comparative example beer, sample is preserved at 20 ℃ of constant temperature, and test result is as shown in table 1:

[0050] Table 1 Beer foam retention test results

[0051]

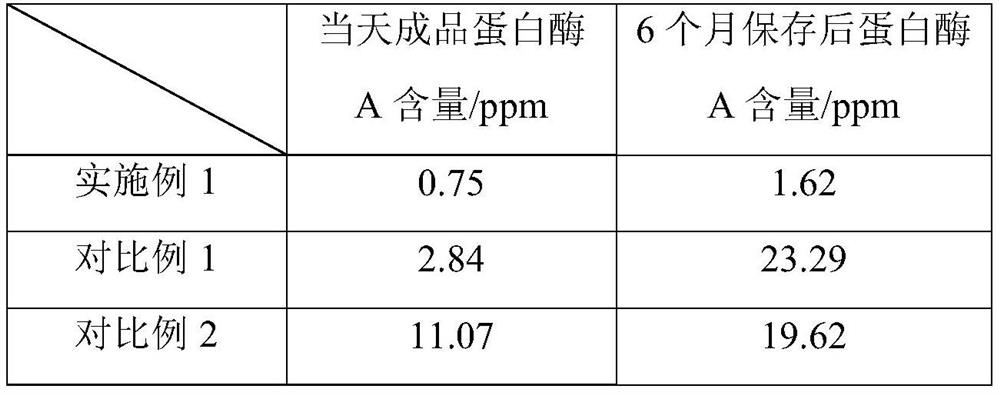

[0052] The protease A content of test embodiment and comparative example beer, sample is preserved at 20 ℃ constant temperature, and test result is as shown in table 2:

[0053] Protease A test result in table 2 beer

[0054]

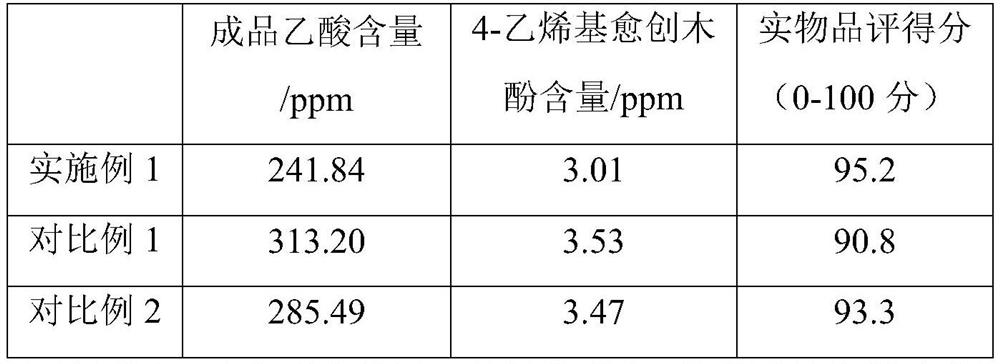

[0055] The acetic acid and 4-vinylguaiacol contents of the beers of the test examples and comparative examples were tested, and flavor evaluation was carried out. The samples were stored at a constant temperature of 20° C. The results are shown in Table 3:

[0056] Table 3 Test results of acetic acid and 4-vinylguaiacol content in beer

[0057]

[0058] From the above results, it can be seen that the secondary fermented Belgian-style white beer in the pop can of Example 1 of the present invention has low acetic acid a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com