A kind of brewing method of cloudy whole malt white beer

A cloudy, white beer technology, applied in the field of beer brewing, to achieve rich and delicate and long-lasting foam performance, soft bitterness, and improve the effect of foam retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

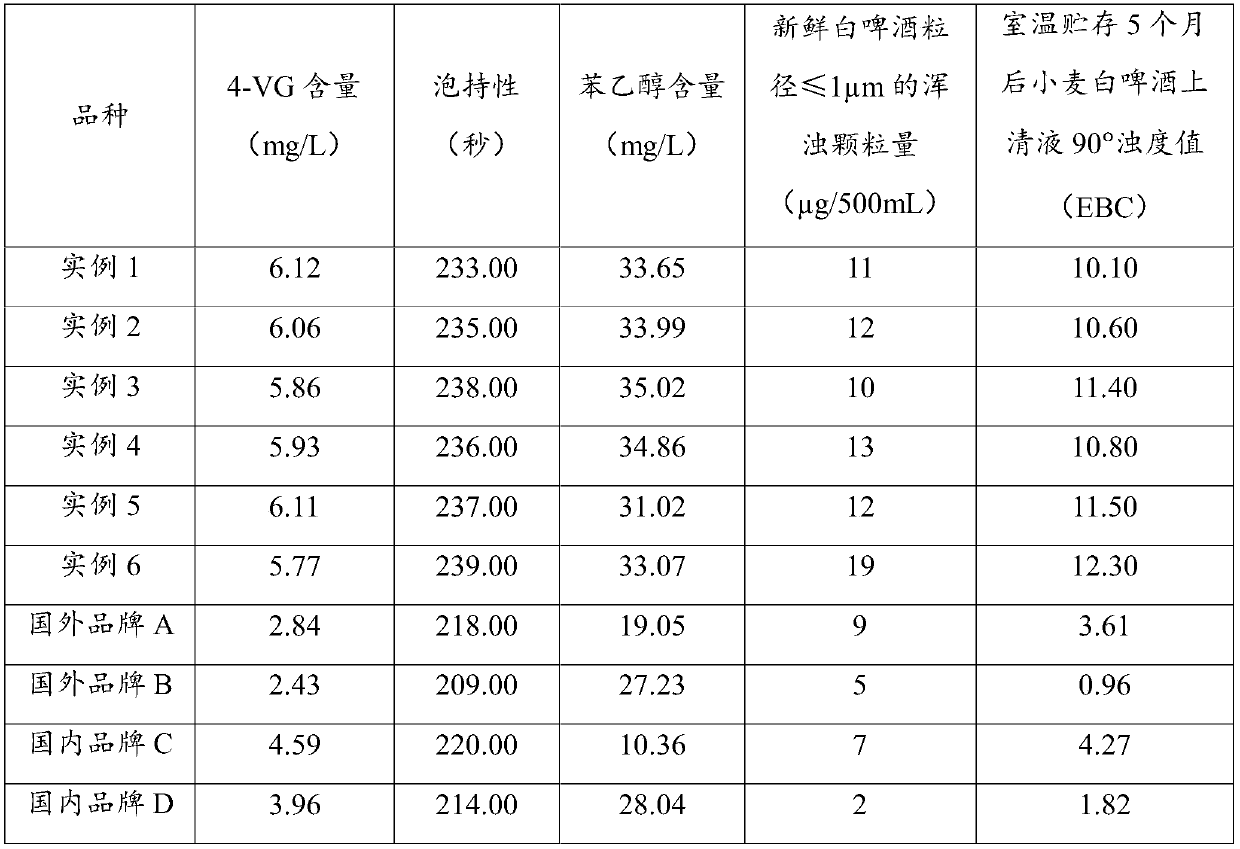

Examples

Embodiment 1

[0040] Weigh the two raw materials according to the weight percentage of 50% barley malt and 50% wheat malt, crush the weighed raw materials, add water (the ratio of material to water is 1:3); The above brewing materials are kept warm for more than 30 minutes to enter the resting stage of low-temperature protein; then the temperature is raised to 68°C, and held for 30 minutes; then the temperature is raised to 72°C, and held for 10 minutes; after passing the iodine test, the temperature is raised to 78°C for wort filtration and grain washing to obtain wort Add 0.05% of wort weight Cascade (Cascade) hops during the wort boiling process, the boiling time is 60 minutes, the boiling intensity is 9%, and the finalized wort is 10-12°P; after the wort is cooled, carry out according to the conventional process After whirlpool sedimentation, it is oxygenated and sent to the fermenter, and the yeast TTA-22, which is specially used for wheat white beer, is added, and the number of yeast i...

Embodiment 2

[0042] Weigh the two raw materials according to the weight percentage of 60% barley malt and 40% wheat malt, crush the weighed raw materials, add water (the ratio of material to water is 1:3.5); The above brewing raw materials are kept warm for more than 30 minutes to enter the resting stage of low-temperature protein; then the temperature is raised to 68°C and held for 30 minutes; then the temperature is raised to 73°C and held for 10 minutes; after passing the iodine test, the temperature is raised to 78°C for wort filtration and grain washing to obtain wort Add 0.05% of wort weight Cascade hops during the wort boiling process, the boiling time is 60 minutes, the boiling intensity is 8%, and the wort is shaped at 10-12°P; after the wort is cooled, it is carried out according to the conventional process After whirlpool sedimentation, it is oxygenated and sent to the fermentation tank, and the yeast TTA-22, which is specially used for wheat white beer, is added, and the number ...

Embodiment 3

[0044] Weigh the two raw materials according to the weight percentage of 70% barley malt and 30% wheat malt, crush the weighed raw materials, add water (the ratio of material to water is 1:4); The above brewing materials are kept warm for more than 30 minutes to enter the resting stage of low-temperature protein; then the temperature is raised to 68°C and held for 30 minutes; then the temperature is raised to 74°C and held for 10 minutes; after passing the iodine test, the temperature is raised to 78°C for wort filtration and grain washing to obtain wort Add 0.05% of wort weight Cascade (Cascade) hops during the wort boiling process, the boiling time is 60 minutes, the boiling intensity is 9%, and the finalized wort is 10-12°P; after the wort is cooled, carry out according to the conventional process After vortex precipitation, it is oxygenated and sent to the fermenter, and the yeast TTA-22, which is specially used for wheat white beer, is added, and the number of yeast in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com