Foam sheet and synthetic leather

A foamed sheet and compound technology, applied in coating, textile and papermaking, etc., can solve the problems of poor smoothness, difficulty in controlling the size and amount of bubbles, hardening of the hand feeling, etc., and achieve the effect of excellent hand feeling and peel strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

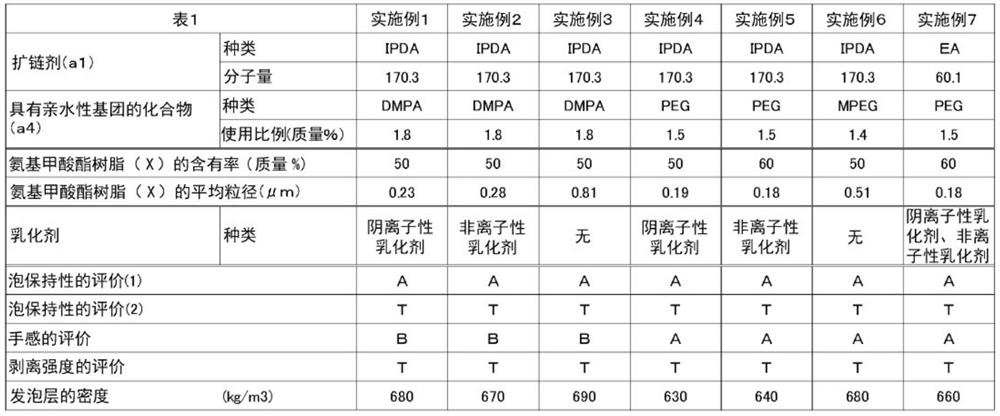

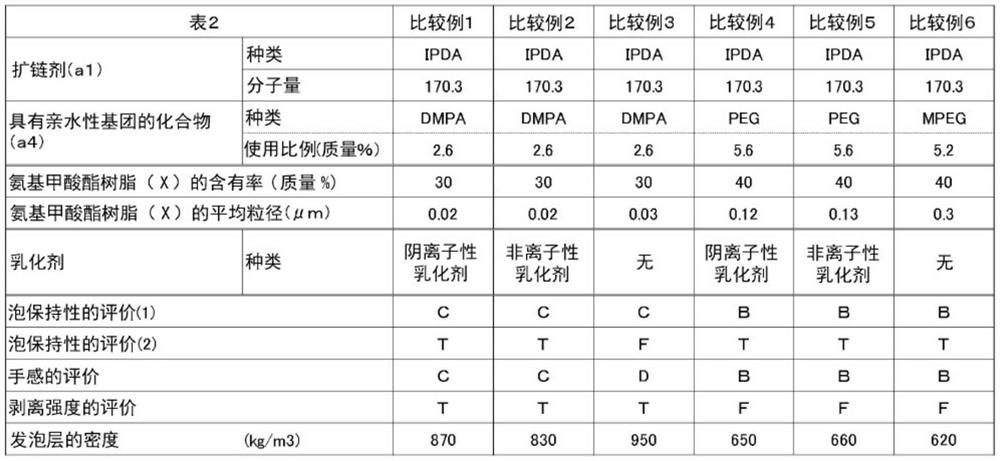

Synthetic example 1

[0073] In the presence of 0.1 parts by mass of stannous octoate, polyether polyol ("PTMG2000" manufactured by Mitsubishi Chemical Corporation, number average molecular weight: 2000, hereinafter abbreviated as "PTMG2000") 1000 parts by mass, 2,2-di 24 parts by mass of methylolpropionic acid (hereinafter abbreviated as "DMPA") and 262 parts by mass of dicyclohexylmethane diisocyanate (hereinafter abbreviated as "HMDI") were reacted at 100°C until NCO% reached 2.1 % by mass to obtain urethane prepolymer A1.

[0074] A1 and triethylamine heated to 70°C, a 20% by mass aqueous solution of sodium dodecylbenzenesulfonate as an emulsifier ("NEOGEN S-20F" manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd.), and water were simultaneously supplied to the twin-screw An emulsion was obtained by mixing with an extruder (TEM-18SS: manufactured by Toshiba Machinery). The respective flow rates of the feed solutions were A1: 10 kg / hour, triethylamine: 0.2 kg / hour, emulsifier aqueous solutio...

Synthetic example 2

[0077] In the presence of 0.1 parts by mass of stannous octoate, 1000 parts by mass of PTMG2000, 24 parts by mass of DMPA and 262 parts by mass of HMDI were reacted at 100° C. until the NCO% reached 2.1 mass % to obtain a prepolymerized carbamate Object A2.

[0078] A2 and triethylamine heated to 70° C., polypropylene polyethylene copolymer ("Pluronic L-64" manufactured by ADEKA Co., Ltd.) as an emulsifier, and water were simultaneously supplied to a twin-screw extruder (TEM-18SS: Toshiba machine) and mixed to obtain an emulsion. The respective flow rates of the feed solutions were A2: 10 kg / hour, triethylamine: 0.2 kg / hour, L-64: 0.5 kg / hour, water: 7.1 kg / hour, and the operating conditions of the twin-screw extruder were 50° C. and 260 rpm.

[0079] Immediately thereafter, a water dilution of IPDA having an amino group content of 95% of the NCO group was added to extend the chain, and finally a polyurethane emulsion (X-2) having a urethane resin content of 50% by mass was o...

Synthetic example 3

[0081] In the presence of 0.1 parts by mass of stannous octoate, 1000 parts by mass of PTMG2000, 24 parts by mass of DMPA and 262 parts by mass of HMDI were reacted at 100°C until the NCO% reached 2.1% by mass to obtain a prepolymerized carbamate Object A3.

[0082] A3 heated to 70° C., triethylamine, and water were simultaneously supplied to a twin-screw extruder (TEM-18SS: manufactured by Toshiba Machinery) and mixed to obtain an emulsion. The respective flow rates of the feed liquids were A3: 10 kg / hour, triethylamine: 0.2 kg / hour, water: 6.6 kg / hour, and the operating conditions of the twin-screw extruder were 50° C. and 260 rpm.

[0083] Immediately thereafter, a water dilution of IPDA having an amino group content of 95% of the NCO group was added to extend the chain to finally obtain a polyurethane emulsion (X-3) having a urethane resin content of 50% by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com