A kind of micro-expansion concrete and preparation method thereof

A technology of micro-expansion concrete and expansion agent, applied in the field of concrete, can solve problems such as concrete cracking, achieve the effects of reducing cracking, reducing secondary production, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

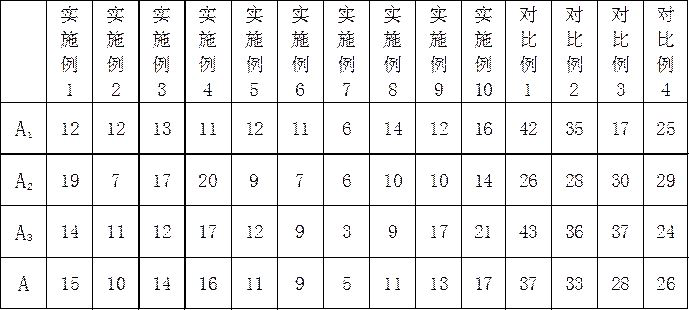

Examples

preparation example 1

[0046] S1. Weigh 5kg of gum arabic and place it in 75kg of drinking water. Stir and dissolve at 80°C at a speed of 30r / min. After the gum arabic is completely dissolved, add 20kg of drinking water to prepare a 5% gum arabic solution.

[0047] Weigh 5kg of gelatin and place it in 60kg of drinking water. After the gelatin swells, add 35kg of drinking water. Stir and dissolve at 60°C at a speed of 30r / min to prepare a 5% gelatin solution. Configure a 5% gelatin solution:

[0048] S2, 5kg chitosan is dissolved with 6kg10% acetic acid solution, stir 15min with the speed of 150r / min;

[0049] S3. Add 6kg5% gum arabic solution to S2, stir for 15min at a speed of 3000r / min, and gradually heat up to 60°C and keep warm for 1h to generate an emulsion;

[0050] S4. Add 6kg of 5% gelatin solution to the emulsion in S3, and stir at a speed of 500r / min for 15min to prepare the inhibitor.

preparation example 2

[0052] S1. Weigh 5kg of gum arabic and place it in 75kg of drinking water. Stir and dissolve at 80°C at a speed of 30r / min. After the gum arabic is completely dissolved, add 20kg of drinking water to prepare a 5% gum arabic solution.

[0053] Weigh 5kg of gelatin and place it in 60kg of drinking water. After the gelatin swells, add 35kg of drinking water. Stir and dissolve at 60°C at a speed of 30r / min to prepare a 5% gelatin solution. Configure a 5% gelatin solution:

[0054] S2, 7kg chitosan is dissolved with 6kg10% acetic acid solution, stir 15min with the speed of 150r / min;

[0055] S3. Add 6kg5% gum arabic solution to S2, stir for 15min at a speed of 3000r / min, and gradually heat up to 60°C and keep warm for 1h to generate an emulsion;

[0056] S4. Add 6kg of 5% gelatin solution to the emulsion in S3, and stir at a speed of 500r / min for 15min to prepare the inhibitor.

preparation example 3

[0058] S1. Weigh 5kg of gum arabic and place it in 75kg of drinking water. Stir and dissolve at 80°C at a speed of 30r / min. After the gum arabic is completely dissolved, add 20kg of drinking water to prepare a 5% gum arabic solution.

[0059] Weigh 5kg of gelatin and place it in 60kg of drinking water. After the gelatin swells, add 35kg of drinking water. Stir and dissolve at 60°C at a speed of 30r / min to prepare a 5% gelatin solution. Configure a 5% gelatin solution:

[0060] S2, 7kg chitosan is dissolved with 7kg10% acetic acid solution, stir 15min with the speed of 150r / min;

[0061] S3. Add 8kg5% gum arabic solution to S2, stir for 15min at a speed of 3000r / min, and gradually heat up to 60°C and keep warm for 1h to generate an emulsion;

[0062] S4. Add 8kg of 5% gelatin solution to the emulsion in S3, and stir at a speed of 500r / min for 15min to prepare the inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com