A thermal cracking treatment device and method for high-moisture garbage

A treatment device and treatment method technology, applied in the direction of combustion method, lighting and heating equipment, combustion type, etc., can solve the problems of inability to continue the thermal cracking internal circulation of the gasifier, waste of gas combustion heat energy, and affect the sealing of the furnace body, etc. Achieve the effect of environmental protection, clean tail gas and maintain thermal cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

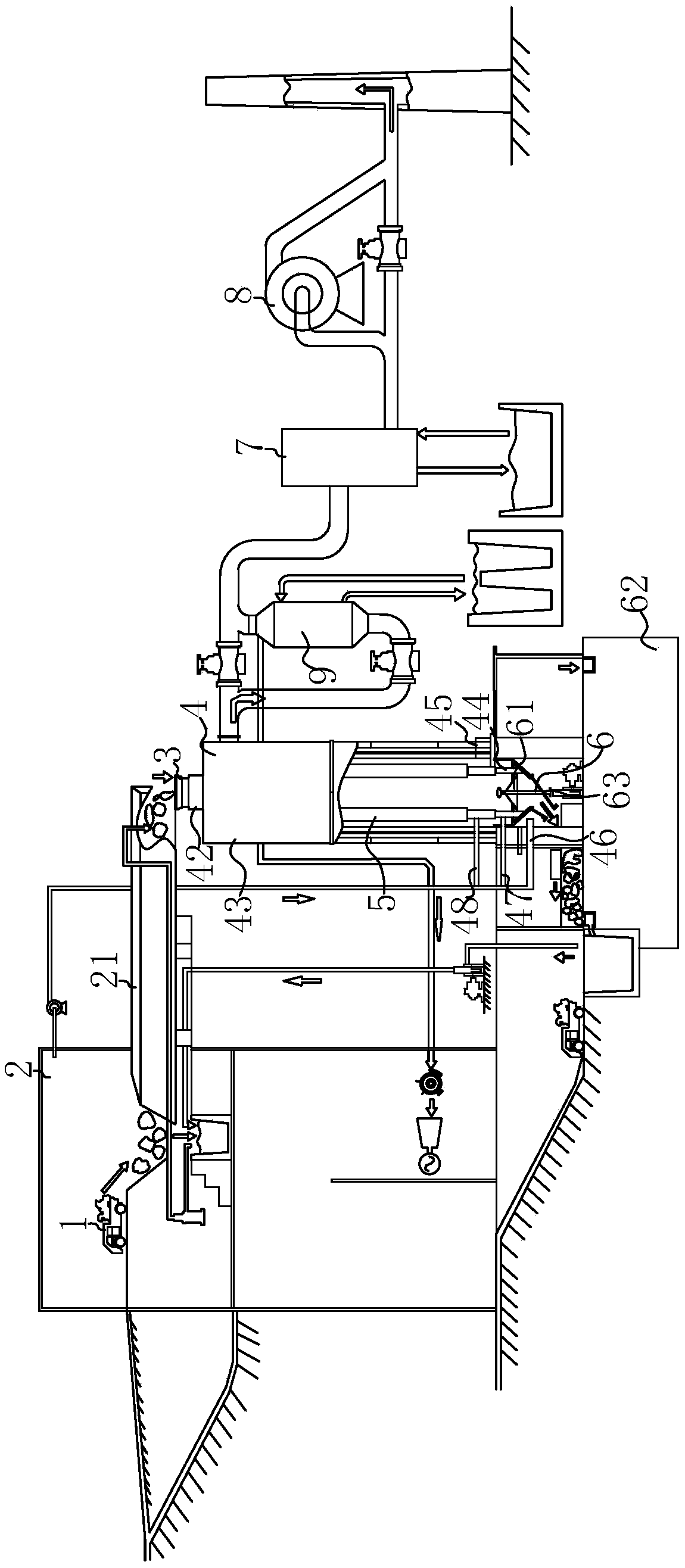

[0054] A high-moisture waste thermal cracking treatment device, such as figure 1 As shown, it includes a garbage truck 1 for transporting garbage, a sealed garbage bin 2 for storing garbage and a conveying device 21 for conveying garbage;

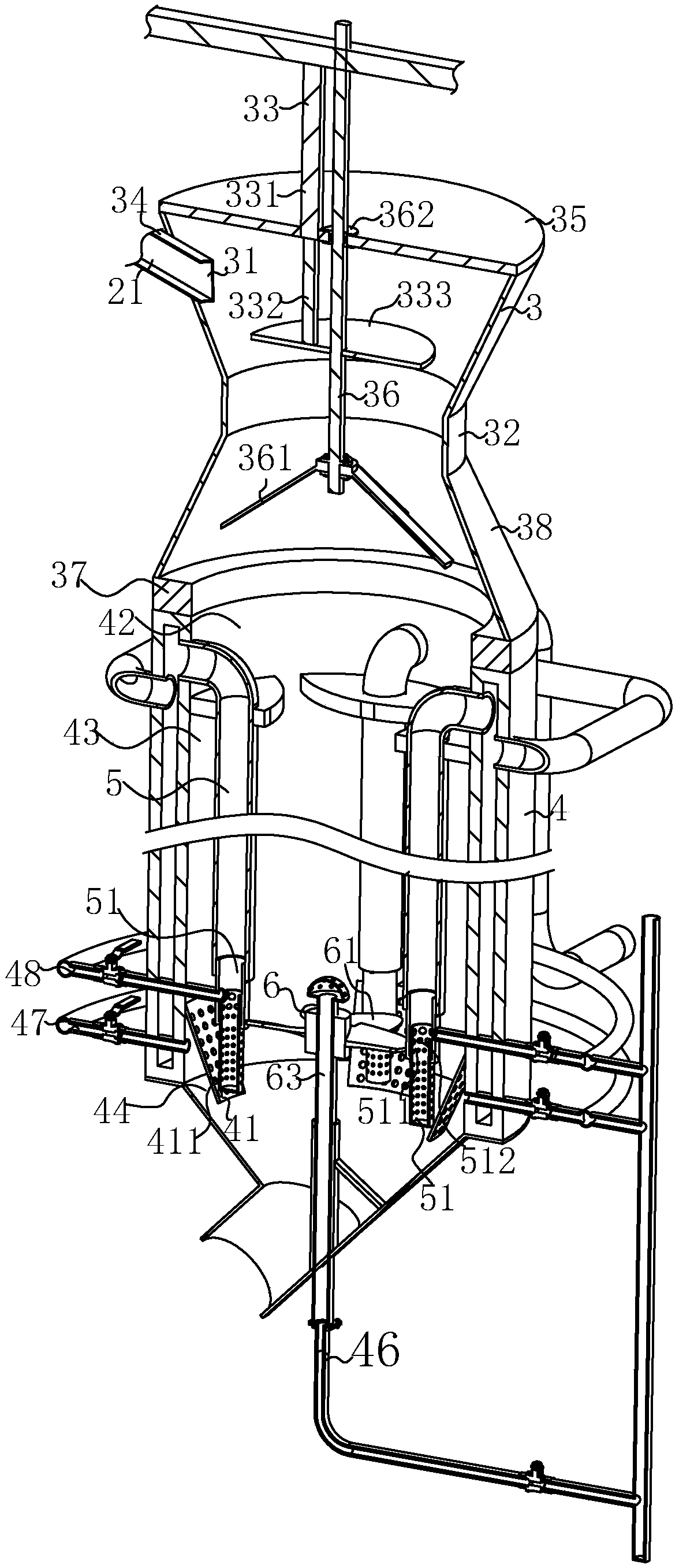

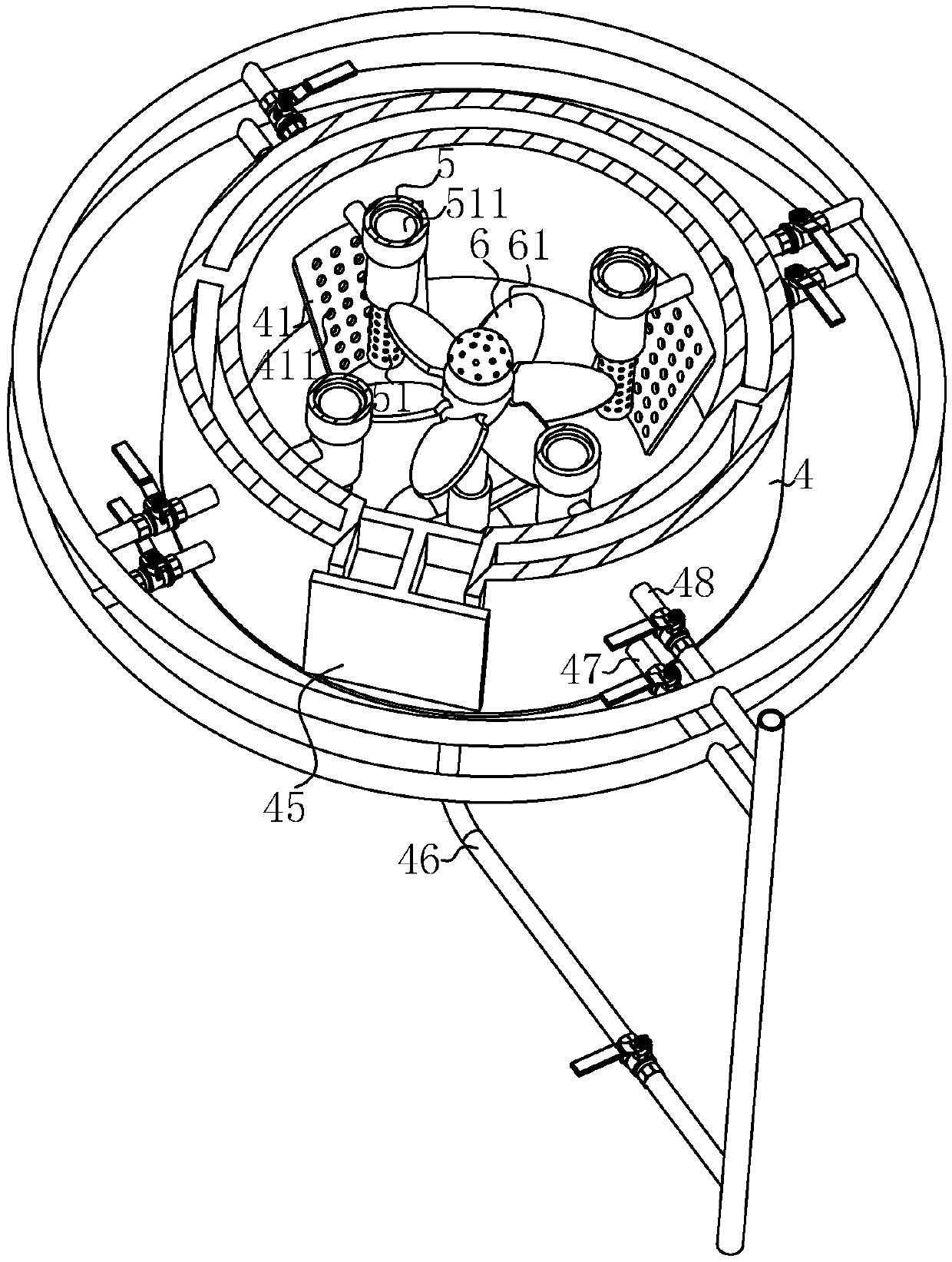

[0055] like figure 1 and figure 2 As shown, the high-moisture waste thermal cracking treatment device also includes a pyrolysis furnace 4 installed at the end of the conveying device 21 to process waste, and a gasket 37 made of ceramics with low thermal conductivity is installed on the top of the pyrolysis furnace 4. The gasket 37 is installed with The double cone-shaped pre-feeding device 3 for throwing and pre-storing garbage, a feeding port 42 is opened between the pre-feeding device 3 and the pyrolysis furnace 4, the upper part of the pre-feeding device 3 is set in a conical shape, and the upper part of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com