Fluidized bed incinerator for special waste

A fluidized bed and incinerator technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems such as space restrictions, incomplete incineration in incinerators, etc., to prevent the generation or secondary generation of dioxins, and reduce retention Time, the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

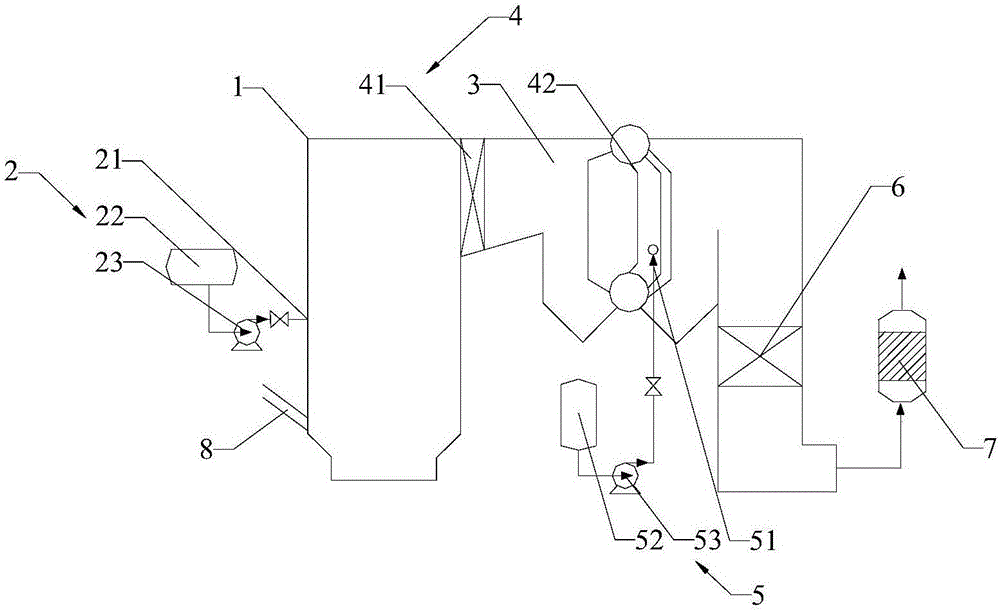

[0028] Please refer to figure 1 , a fluidized bed incinerator for special waste, comprising a fluidized bed incinerator body 1, a warming device 2, a flue 3 connected to the upper part of the dilute phase area of the body 1, and a steam boiler 4 sequentially arranged on the flue 3 , quenching device 5, flue gas recovery device 6 and tail gas treatment device 7;

[0029] The warming device 2 includes an oil gun 21 connected to the dilute phase area of the body 1; the oil gun 21 is connected to the diesel tank through an oil pipe, and the oil pipe is provided with an oil pump 23; the dilute phase area of the body 1 is provided with a The temperature controller of the heating device 2;

[0030] The feed pipe 8 is connected to the lower side of the body 1 of the fluidized bed incinerator, and the special waste enters the dense-phase area at the lower part of the body 1 through the feed pipe 8, and the flue gas generated after combustion stays in the dilute-phase area of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com