A method for extracting tungsten from tungsten-containing raw materials by using hydrous sodium silicate

A technology of hydrous sodium silicate and raw materials, which is applied in the extraction of tungsten, using hydrous sodium silicate to extract tungsten from tungsten-containing raw materials, can solve problems such as the difficulty of extracting tungsten resources, and achieve the benefits of large-scale production and application, and the contact area Increase and prevent the effect of secondary generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

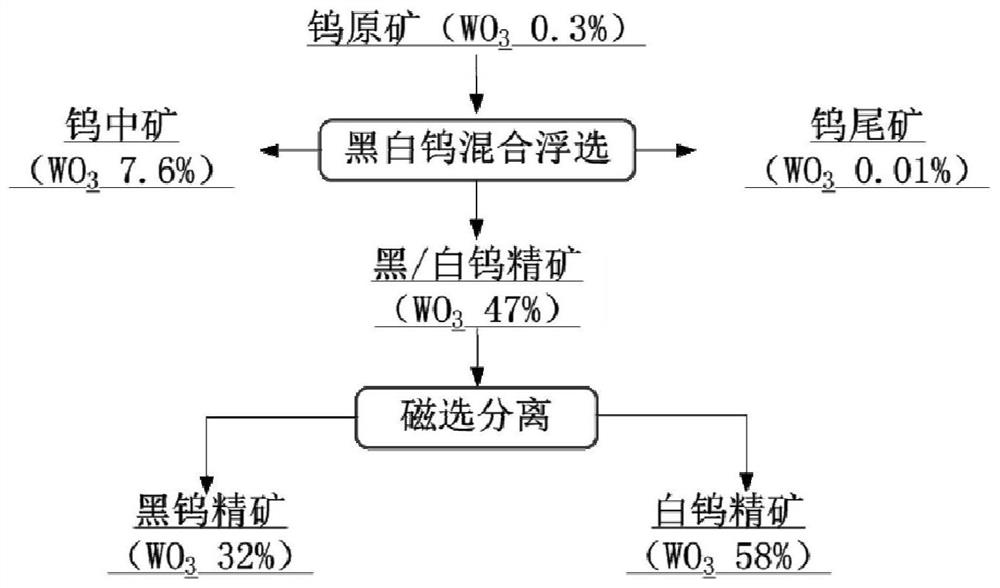

[0028] The principle process of a black / scheelite concentrator is as follows figure 2 As shown, the black and white tungsten concentrates in the concentrator all meet the concentrate standard, but the tungsten medium ore products are difficult to meet the metallurgical requirements due to their fine particle size, so they are piled up in warehouses; in addition, the existing black and white tungsten ore metallurgy is usually Separated, so a large number of magnetic separators are needed in the concentrator to separate the black / scheelite concentrate by magnetic separation.

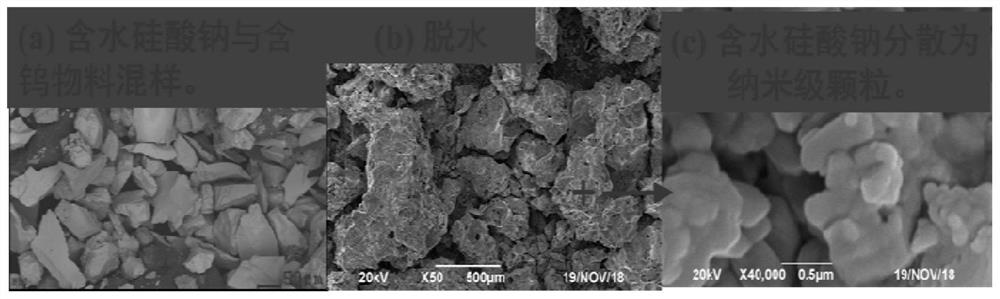

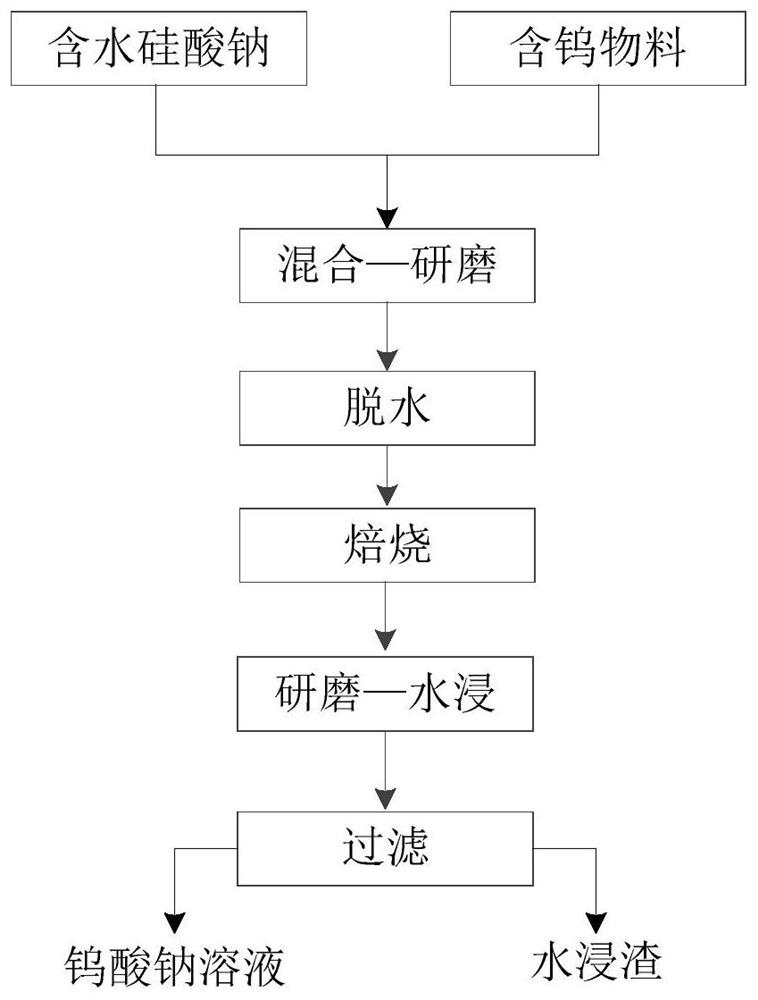

[0029] Utilize the method of the present invention to adopt hydrous sodium silicate as tungsten ore decomposition reagent, carry out sodiumization roasting and water immersion test to scheelite concentrate, black tungsten concentrate, black / scheelite mixed concentrate and tungsten middle ore respectively, concrete operation The steps are as follows: First, mix the sodium silicate with water and the tungst...

Embodiment 2

[0041] A tungsten smelter produces ammonium paratungstate by alkaline pressure cooking, a large amount of tungsten slag will be produced during the alkaline leaching process, and WO in tungsten slag 3 The content fluctuates between 1% and 3%, and the tungsten slag is corrosion slag with extremely fine particle size, and the traditional dressing and smelting process cannot effectively extract the tungsten element.

[0042] Take WO 3 The tungsten slag with a content of 1.1% is mixed evenly with sodium metasilicate nonahydrate according to the mass ratio of 1:0.3, ground to less than 74 μm, dehydrated at 200°C for 5 minutes, and then heated to 850°C and roasted for 30 minutes, the roasted material is ground Put it into water for leaching to less than 45μm, according to the liquid-solid ratio of 2:1, the leaching temperature is 50°C, the leaching stirring time is 30 minutes, and the sodium tungstate leaching solution with a leaching rate of 95.8% is obtained by filtration, and the...

Embodiment 3

[0050] Take a tungsten-containing waste catalyst with a W content of 4.3% and sodium metasilicate nonahydrate, mix evenly according to the mass ratio of 1:0.4, grind to less than 74 μm, dehydrate at 200 ° C for 5 minutes, continue to heat up to 700 ° C and roast for 15 minutes , Grind the calcined material to less than 45μm and put it into water for leaching. According to the liquid-solid ratio of 4:1, the leaching temperature is 80°C, the leaching stirring time is 30 minutes, and the sodium tungstate leaching solution with a leaching rate of 98.4% is obtained by filtration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com