Method for removing impurities on surface of lithium-lanthanum-zirconium-oxygen electrolyte of solid-state lithium battery

A technology of lithium lanthanum zirconium oxide and lithium lanthanum zirconium oxide sheet is applied in the field of oxide solid electrolyte, which can solve the problems of destroying the properties of samples, restricting the intrinsic properties of lithium lanthanum zirconium oxygen, and improving the removal effect, so as to ensure complete removal and removal. The process is controllable and the effect of preventing secondary generation

Active Publication Date: 2021-07-13

SUN YAT SEN UNIV

View PDF2 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, these methods still have limitations: since the annealing process is carried out in air, the lithium lanthanum zirconium oxygen samples treated by this method still inevitably generate Li 2 CO 3 , and the organic adsorption layer cannot be removed [6,7] ;Physical methods such as polishing may destroy the properties of the sample, and it is difficult to achieve a good removal effect [3] ;Chemical methods such as pickling introduce additional ingredients [8]

At present, there is no relevant method that can completely remove the surface impurities of lithium lanthanum zirconium oxide without causing additional effects, which restricts the research and further utilization of the intrinsic properties of lithium lanthanum zirconium oxide

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

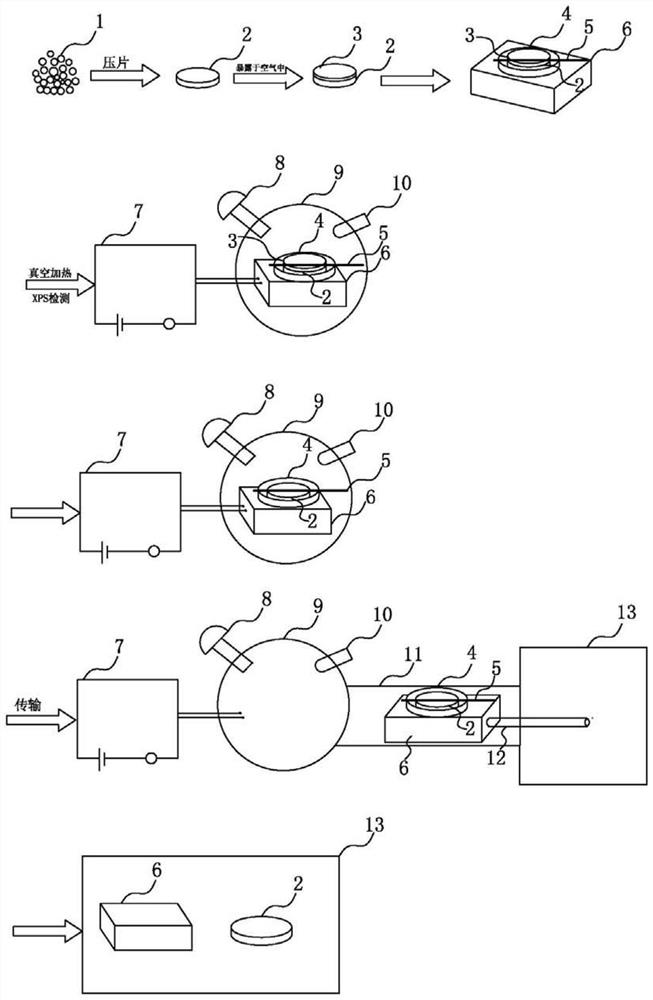

[0040] For the convenience of those skilled in the art to understand, below in conjunction with embodiment and appended figure 1 - attached Figure 6 , to further illustrate the present invention, the content mentioned in the embodiment is not to limit the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

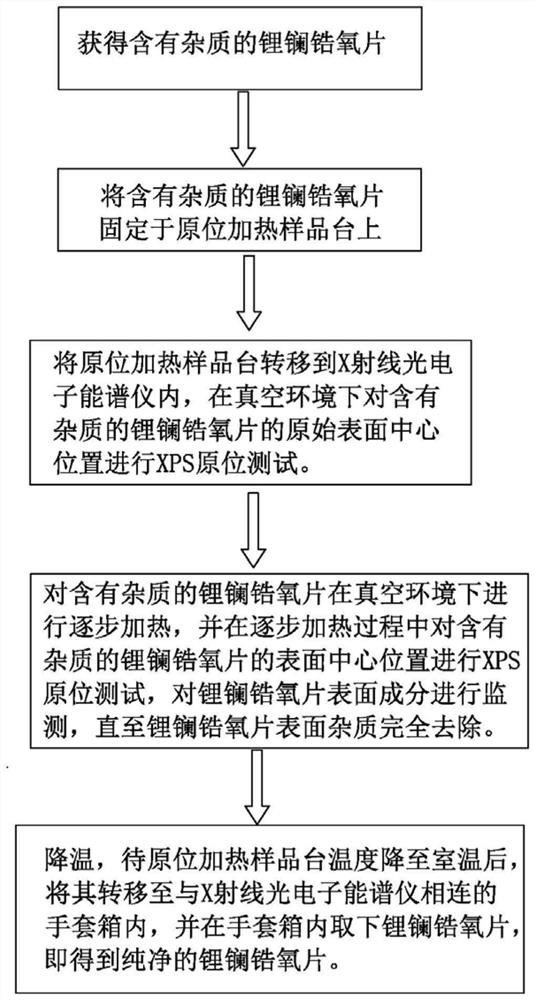

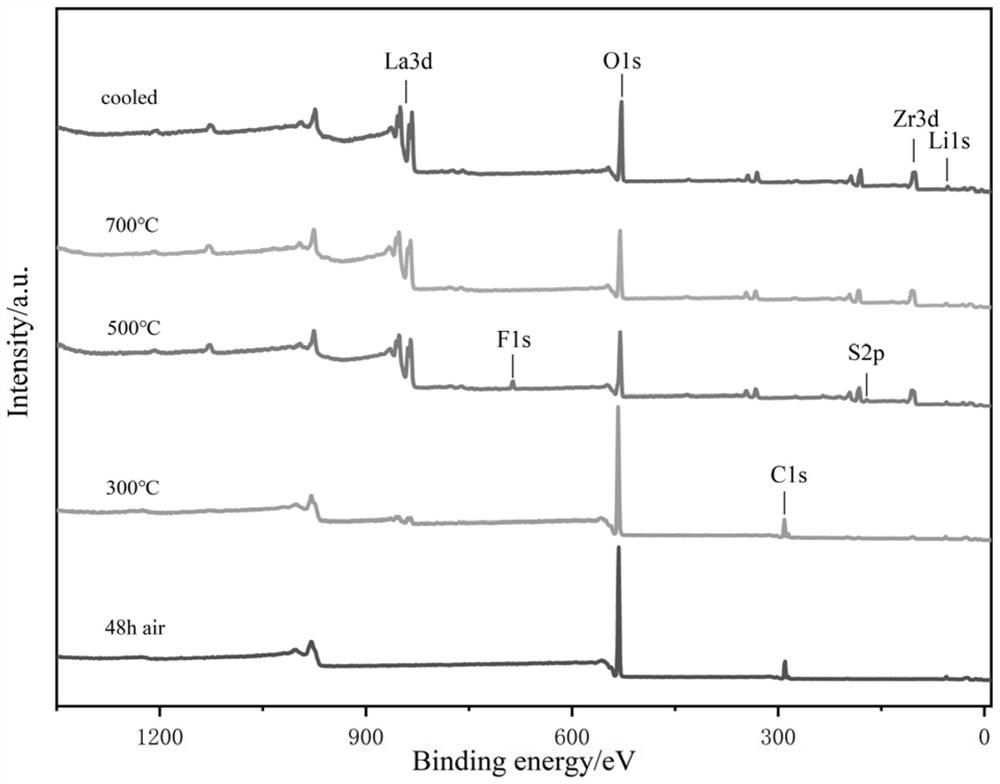

The invention relates to the field of oxide solid electrolytes, in particular to a method for removing impurities on the surface of a lithium-lanthanum-zirconium-oxygen electrolyte of a solid-state lithium battery. The method comprises the following steps of: transferring a lithium-lanthanum-zirconium-oxygen sheet containing impurities into an analysis chamber of an X-ray photoelectron spectrometer, and gradually heating in a vacuum environment to remove the impurities on the surface of the lithium-lanthanum-zirconium-oxygen sheet; carrying out in-situ XPS testing on the surface of the lithium-lanthanum-zirconium-oxide sheet in the step-by-step heating process; after impurities on the surface of the lithium-lanthanum-zirconium-oxide sheet are removed, cooling the in-situ heating sample table to the room temperature and then transferring the in-situ heating sample table into a glove box connected with the X-ray photoelectron spectrometer, and taking down the lithium-lanthanum-zirconium-oxide sheet from the in-situ heating sample table to obtain the pure lithium-lanthanum-zirconium-oxide sheet. According to the method, vacuum annealing and in-situ XPS testing are used, removal of the impurity layer on the surface of the lithium-lanthanum-zirconium-oxide sheet is combined with surface component monitoring, and high-precision removal of impurities on the surface of the lithium-lanthanum-zirconium-oxide sheet is achieved.

Description

technical field [0001] The invention belongs to the field of oxide solid electrolytes, and in particular relates to a method for removing impurities on the surface of a lithium-lanthanum-zirconium-oxygen electrolyte for a solid-state lithium battery. Background technique [0002] Solid-state lithium batteries have attracted much attention due to their high safety, high energy density and other advantages. There are many kinds of solid electrolytes used in them, among which the garnet-type solid electrolyte lithium lanthanum zirconium oxide Li 7 La 3 Zr 2 o 12 (LLZO) has attracted much attention due to its high ionic conductivity and stability towards lithium anodes. [1,2] . But the solid electrolyte is unstable in the air, firstly with H 2 O reacts to generate LiOH, which is further combined with CO 2 The reaction produces Li 2 CO 3 [3] . The reaction process is rapid and unavoidable, and the reaction layer is mainly located on the surface of the sample. In additio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B41/91C04B41/00H01M10/0562

CPCC04B41/00C04B41/0072C04B41/91H01M10/0562Y02E60/10

Inventor 周逸凡谢方艳宋树芹杨慕紫陈建龚力

Owner SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com