Determination method for permeability of hydrate-containing reservoir in hydrate phase change process

A hydrate-containing, measurement method technology, applied in the direction of permeability/surface area analysis, measuring device, suspension and porous material analysis, etc., can solve the problem of inability to measure the permeability of hydrate-containing reservoirs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

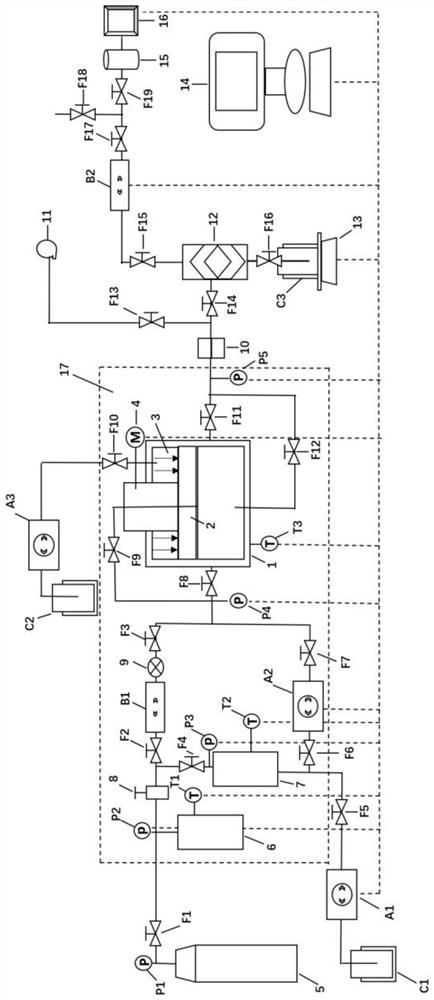

Image

Examples

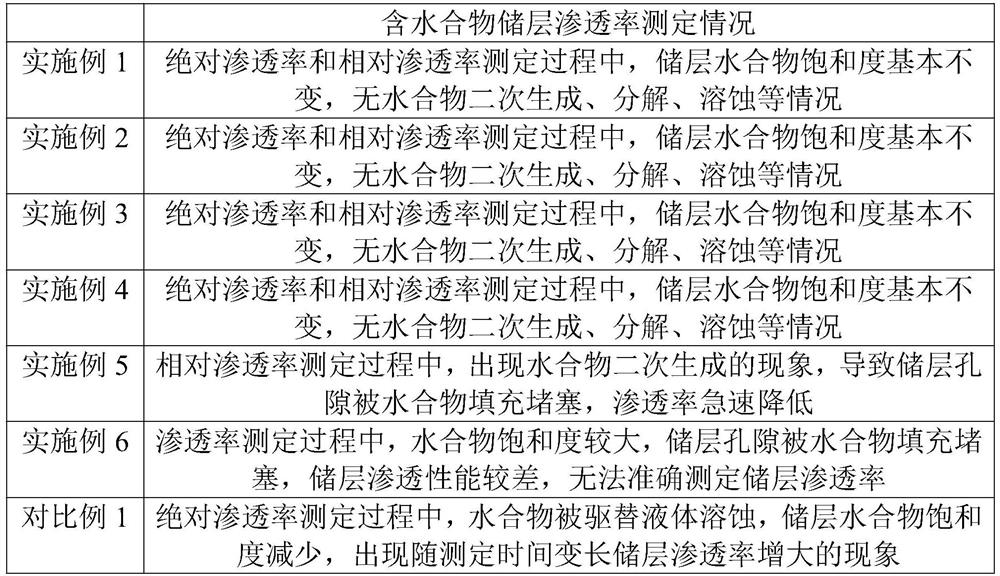

Embodiment 1

[0152]Methane hydrate

[0153]Step 1: Preparation of the reservoir model, washed 100 destination quartz sand and washed 3-5 times with deionized water. After drying, fill it in the hydrate reactor 1, gramilastically, form a densely uniform reservoir model.

[0154]Step 2: Reservoir model applies an effective stress: using the reservoir model in the hydrate reactor plus the reservoir in the hydrate, the effective stress PEFF Set to 2MPa, at this time, the pressure POver 2MPa, where PEFF = POver -Phole Phole For reservoir pores, MPA. At the same time, the size of the upper layer pressure loaded by the displacement sensor 4 is recorded.

[0155]Step 3: Calculate the reservoir porosity: Keep the vacuum pump 0.1MPa to remove the reservoir model for 1-3 hours, the deionized water is injected into the model with 10 ml / min, and then continues to inject 10 minutes after filled with water, record this Cumulative injection volume of deionized water1Cumulative output volume V2Then the pore volume is V...

Embodiment 2

[0168]Ethane hydrate

[0169]Step 1: Preparation of the reservoir model, washed 300 destination quartz sand and washed 3-5 times with deionized water. After drying, fill in the hydrate reaction kettle 1, and consolidate layer by layer, form a uniform reservoir model.

[0170]Step 2: Reservoir model applies an effective stress: using the reservoir model in the hydrate reactor plus the reservoir in the hydrate, the effective stress PEFF Set to 4 MPa, at this time, the upper pressure POver For 4MPa, where PEFF = POver -Phole Phole For reservoir pores, MPA. At the same time, the size of the upper layer pressure loaded by the displacement sensor 4 is recorded.

[0171]Step 3: Calculate the reservoir porosity: Keep the vacuum pump 0.1MPa to remove the reservoir model for 1-3 hours, the deionized water is injected into the model with 10 ml / min, and then continues to inject 10 minutes after filled with water, record this Cumulative injection volume of deionized water1Cumulative output volume V2The...

Embodiment 3

[0184]Methane and ethane hydrate

[0185]Step 1: Preparation of the reservoir model, washed with 500 destination quartz sand and washed 3-5 times with deionized water, and then fill in the hydrate reactor 1 after drying, gramilastically consolidate, forming a densely uniform reservoir model.

[0186]Step 2: Reservoir model applies an effective stress: using the reservoir model in the hydrate reactor plus the reservoir in the hydrate, the effective stress PEFF Set to 3MPa, at this time, the upper pressure POver 3MPa, where PEFF = POver -Phole Phole For reservoir pores, MPA. At the same time, the size of the upper layer pressure loaded by the displacement sensor 4 is recorded.

[0187]Step 3: Calculate the reservoir porosity: Keep the vacuum pump 0.1MPa to remove the reservoir model for 1-3 hours, the deionized water is injected into the model with 10 ml / min, and then continues to inject 10 minutes after filled with water, record this Cumulative injection volume of deionized water1Cumulative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com