A kind of concrete admixture and its preparation method and application method

A technology of concrete admixture and defoamer, which is applied in the field of concrete admixture, can solve problems such as failure to meet engineering requirements, serious strength loss, and hidden dangers of engineering quality stability, so as to speed up condensation, increase early strength, and reduce losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

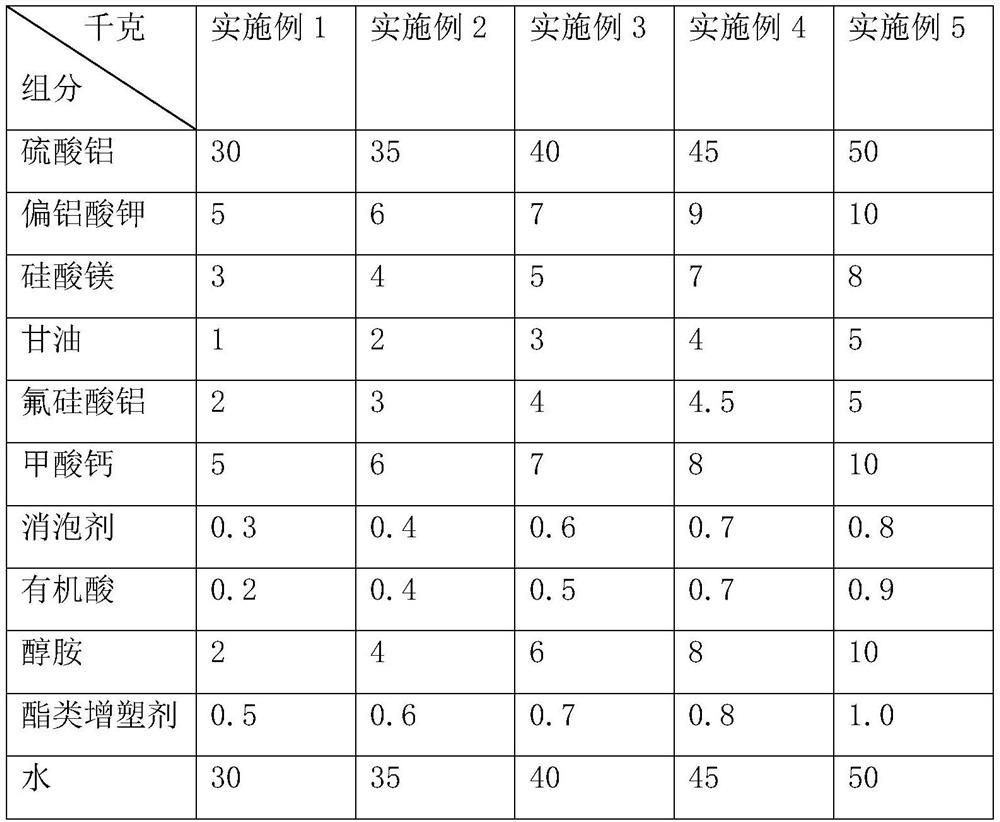

Embodiment 1

[0041] Embodiment 1: a kind of preparation method of concrete admixture comprises the following steps:

[0042] S1, according to the proportioning in table 1, 30kg aluminum sulfate is sieved and pulverized, crosses 80 mesh sieves;

[0043] S2. Heat 30kg of water to 55°C, add aluminum sulfate into the water, and keep stirring until the aluminum sulfate is completely dissolved;

[0044] S3, add 5kg potassium metaaluminate and 2kg aluminum fluorosilicate, stir constantly, stir for 30min;

[0045] S4. Slowly add 2kg of alcohol amine, and stir at 25°C for 10 minutes, add 0.2kg of organic acid, and raise the temperature to 55°C, keep the temperature for 30 minutes, the alcohol amine is triethanolamine, and the organic acid is benzoic acid;

[0046] S5. Add 5kg of calcium formate and 3kg of magnesium silicate, heat up to 60°C, and stir for 10min;

[0047] S6. Add 1 kg of glycerin, 0.3 kg of defoamer and 0.5 kg of ester plasticizer, and stir evenly to obtain a concrete admixture. Th...

Embodiment 2

[0050] Embodiment 2: a kind of preparation method of concrete admixture comprises the following steps:

[0051] S1, according to the proportioning in table 1, 35kg aluminum sulfate is sieved and pulverized, crosses 100 mesh sieves;

[0052] S2. Heat 35kg of water to 65°C, add aluminum sulfate into the water, and keep stirring until the aluminum sulfate is completely dissolved;

[0053] S3, add 6kg potassium metaaluminate and 3kg aluminum fluorosilicate, stir continuously, stir for 35min;

[0054] S4. Slowly add 4kg of alcohol amine, and stir at 28°C for 15 minutes, add 0.4kg of organic acid, and raise the temperature to 65°C, keep the temperature for 45 minutes, the alcohol amine is diethanolamine, and the organic acid is citric acid;

[0055] S5. Add 6kg calcium formate and 4kg magnesium silicate, heat up to 70°C, and stir for 15min;

[0056] S6. Add 2 kg of glycerin, 0.4 kg of defoamer and 0.6 kg of ester plasticizer, and stir evenly to obtain a concrete admixture. The def...

Embodiment 3

[0057] Embodiment 3: a kind of preparation method of concrete admixture comprises the following steps:

[0058] S1, according to the proportioning in table 1, sieve and pulverize 40kg aluminum sulfate, cross 150 mesh sieves;

[0059] S2. Heat 40kg of water to 75°C, add aluminum sulfate into the water, and keep stirring until the aluminum sulfate is completely dissolved;

[0060] S3, add 7kg potassium metaaluminate and 4kg aluminum fluorosilicate, stir constantly, stir 40min;

[0061] S4. Slowly add 6kg of alcohol amine, and stir at 30°C for 20 minutes, add 0.5kg of organic acid, and raise the temperature to 75°C, keep the temperature for 60 minutes, the alcohol amine is diethanolamine, and the organic acid is acetic acid;

[0062] S5. Add 7kg of calcium formate and 5kg of magnesium silicate, heat up to 80°C, and stir for 20min;

[0063] S6. Add 3 kg of glycerin, 0.6 kg of defoamer and 0.7 kg of ester plasticizer, and stir evenly to obtain a concrete admixture. The defoamer i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com