A method for recycling waste fly ash in iron ore sintering process

A technology of garbage fly ash and sintering process, which is applied in the direction of improving process efficiency, etc. It can solve the problems of secondary pollution of the environment, high content, and increased residual amount of harmful elements in sintered ore, so as to achieve the effect of increasing production and preventing secondary generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

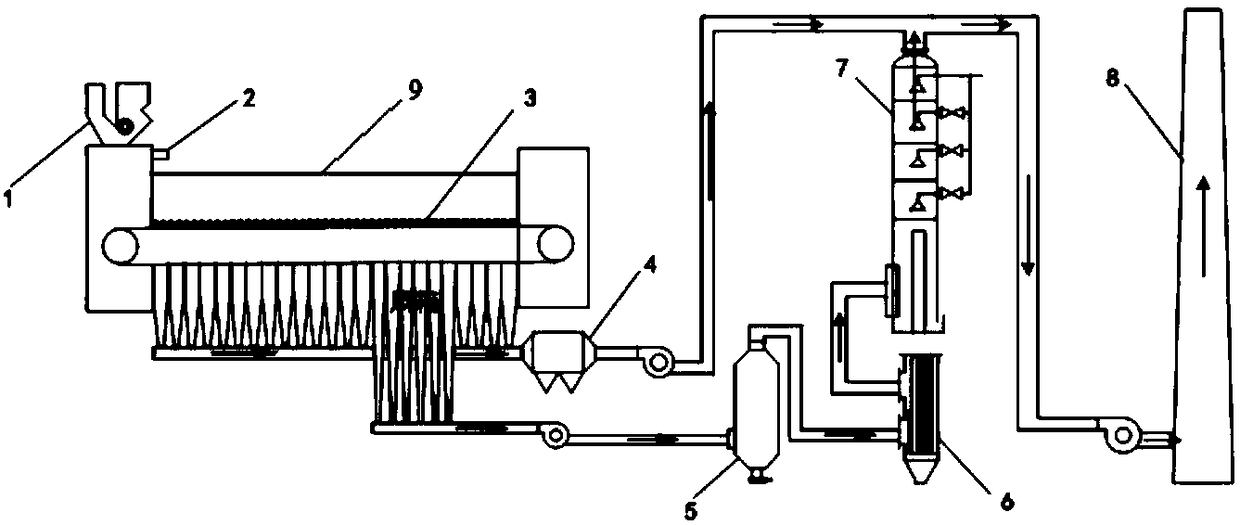

[0039] Such as figure 1 As shown, a technology for recycling waste fly ash in iron ore sintering process is to mix waste fly ash with high zinc, high lead, high alkali metal, high sulfur iron-containing raw materials in the sintering raw materials, and biomass charcoal beforehand. Make a 14mm ball core, control the mass ratio of garbage fly ash / iron-containing raw material in the ball core to be 0.2, the molar ratio of (2Pb+2Zn+K+Na) / Cl to be 1.0, and add 4% of biochar, and then Coat the surface of the ball core with fine-grained magnetite to form a spherical shell with a thickness of 2 mm, and prepare a small ball with a double-layer structure. After low-temperature drying and dehydration, it is used for sintering as the bottom layer of the sintering machine, replacing the traditional 15~ 20mm finished sinter ore paving base material. After the fly ash pellets are placed on the bottom of the sintering machine, other sintering raw materials are prepared, mixed and granulated ...

Embodiment 2

[0041] Such as figure 1 As shown, a technology for recycling waste fly ash in iron ore sintering process is to mix waste fly ash with high zinc, high lead, high alkali metal, high sulfur iron-containing raw materials in the sintering raw materials, and biomass charcoal beforehand. Make a 16mm ball core, control the mass ratio of garbage fly ash / iron-containing raw material in the ball core to be 0.5, the molar ratio of (2Pb+2Zn+K+Na) / Cl to be 0.7, and add 6% of biochar, and then Coat the surface of the ball core with fine-grained magnetite to form a spherical shell with a thickness of 2 mm, and prepare a small ball with a double-layer structure. After low-temperature drying and dehydration, it is used for sintering as the bottom layer of the sintering machine, replacing the traditional 15~ 20mm finished sinter ore paving base material. After the fly ash pellets are placed on the bottom of the sintering machine, other sintering raw materials are prepared, mixed and granulated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com