A horizontal well fracturing filling natural gas hydrate efficiency-enhancing production equipment and method

A horizontal well and natural gas technology, applied in the field of energy and environment, can solve the problems of short pressure transmission distance, small decomposition area, wellhead clogging, etc., and achieve the effect of promoting safety, solving easy blockage problems, and maintaining large-scale pressure reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

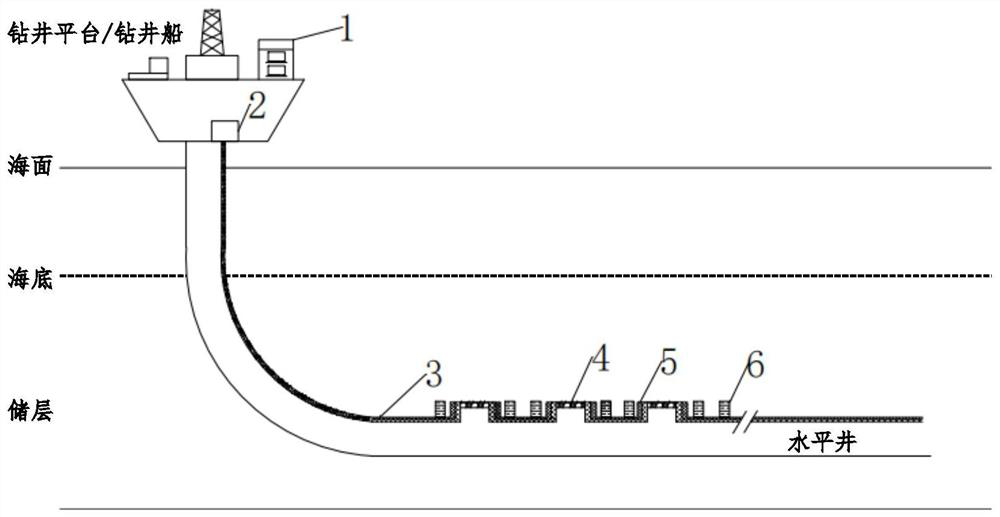

[0024] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0025] The method for using the above-mentioned device to increase the efficiency of marine natural gas hydrate exploitation includes the following steps:

[0026] The first step is to drill in the gas hydrate target area, drill the wellbore equipped with fracturing and sand control systems into the hydrate reservoir, form a horizontal well with an inclination angle of 80-90 degrees, and complete the joint debugging of each system , to collect temperature and pressure data around the wellbore;

[0027] The second step is to set the production pressure on the production platform, and turn on the gas collection and water collection pumps to carry out initial depressurization and gas collection; adopt the gradient decompression method, and adjust the production pressure step by step according to the gas production rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com