A system to monitor and avoid secondary formation during hydrate decomposition

A hydrate decomposition and secondary generation technology, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as blocked pipelines, safety accidents, reduced gas production rate and total gas production, and eliminates The effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

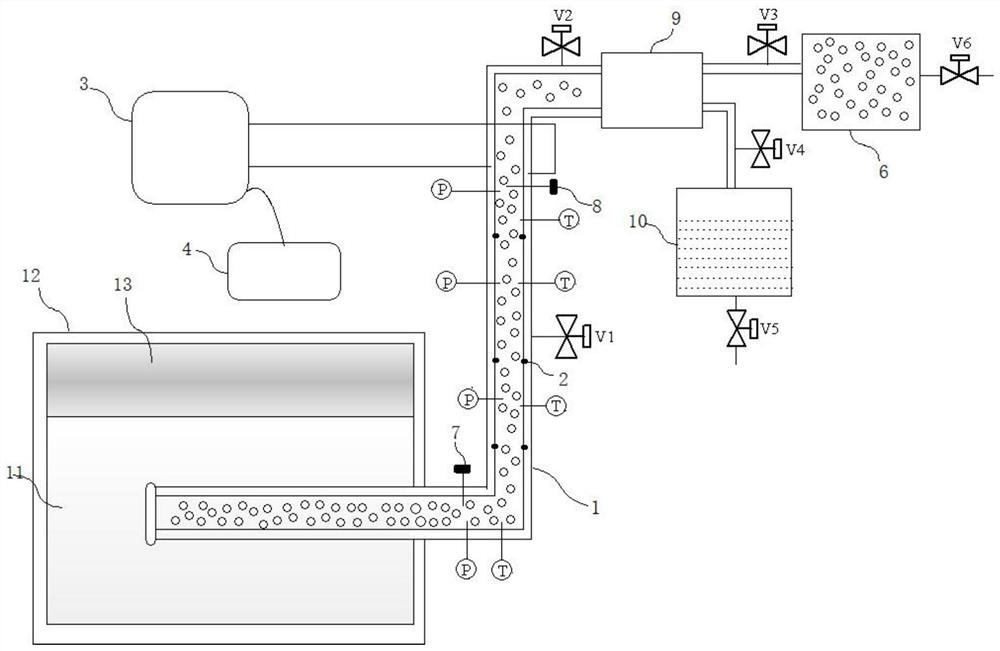

[0027] refer to figure 1 The system provided in this embodiment for monitoring and avoiding the secondary generation of hydrates during the decomposition process includes a decomposition casing pipeline 1 , a resistivity detection probe 2 , an external power supply heating device 3 and a data acquisition and analysis interconnection device 4 .

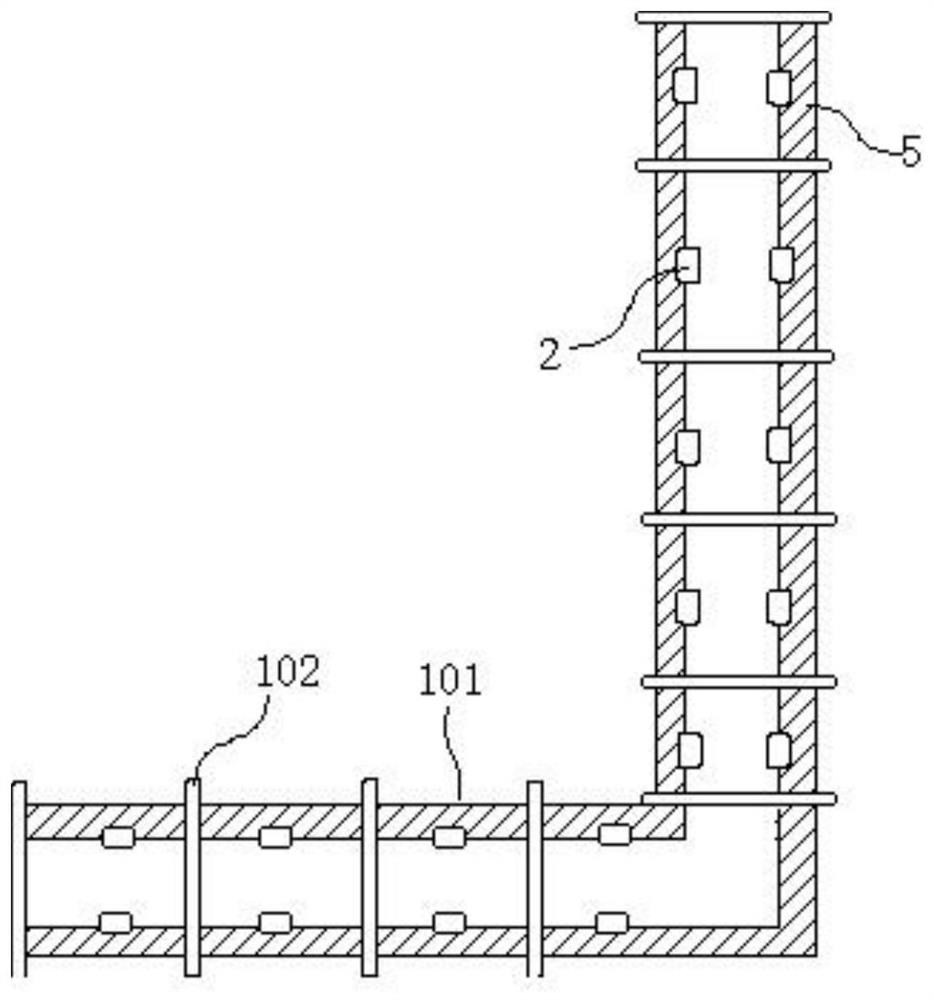

[0028] Among them, such as figure 2 As shown, the decomposition casing pipeline 1 adopts a rigid casing structure, the inner and outer sides of the pipe wall are made of rigid structural materials, and a heating element is arranged inside the casing, and the heating element is connected to the external power heating device 3; specifically , in an embodiment, the heating element is a flexible resistance wire 5, and the flexible resistance wire 5 is wound in the decomposition sleeve pipeline 1; The flexible resistance wire 5 is wound inside the jacket, and the resistance wire 5 is powered by an external power heating device 3 to genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com