Garbage incinerating exhaust gas using environment-friendly and energy-saving device

A technology of waste incineration, environmental protection and energy saving, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of no dioxin detection and treatment control device, high dioxin detection and treatment technology, and high operating costs, and achieve volume reduction. Thorough performance, good economic and social benefits, and sufficient combustion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

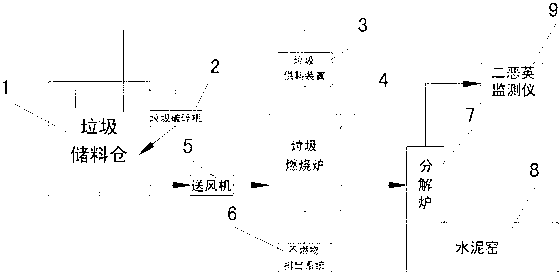

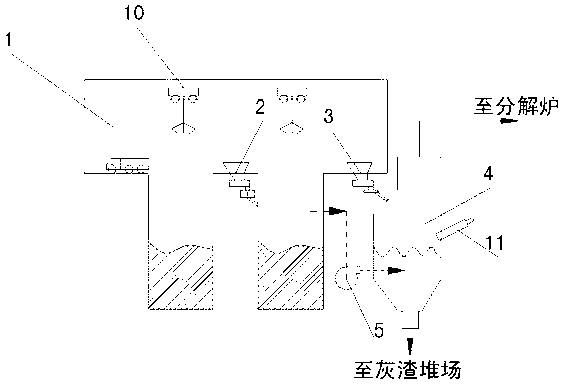

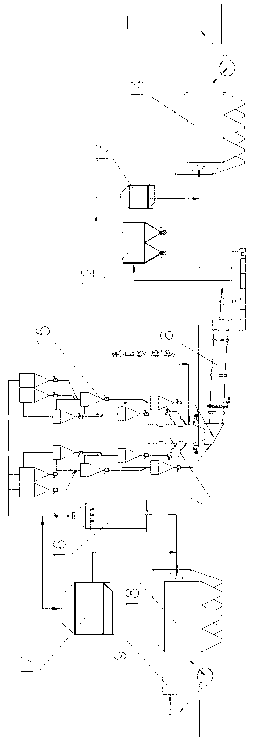

[0032] The energy-saving and environment-friendly device for waste gas utilization of waste incinerators provided by the present invention includes a waste storage bin 1, a waste crusher 2, a waste supply device 3, a waste incinerator 4, a decomposition furnace 7 in dry cement production, and a rotary cement Kiln 8, dioxin detector 9, described garbage supply device 3 is communicated with the garbage inlet of garbage incinerator 4, and the exhaust port of described garbage incinerator 4 is communicated with described decomposition furnace 7 through pipeline, and described The material outlet of the calciner 7 communicates with the feed inlet of the cement kiln 8 .

[0033] The waste incinerator 4 can be a circulating fluidized bed incinerator, a rotary kiln incinerator or a grate-shaped incinerator.

[0034] The bottom of the garbage incinerator is provided with a non-combustible discharge system 6, and the discharge device of the non-combustible discharge system 6 communicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com