Anti-air-backflow smoke tube of gas water heater

A gas water heater and smoke pipe technology, which is applied in the directions of fluid heaters, induced drafts, combustion methods, etc., can solve the problems of reducing efficiency, affecting gas combustion, and freezing cracking of water heaters, so as to improve the wind pressure resistance performance, improve the combustion state, The effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

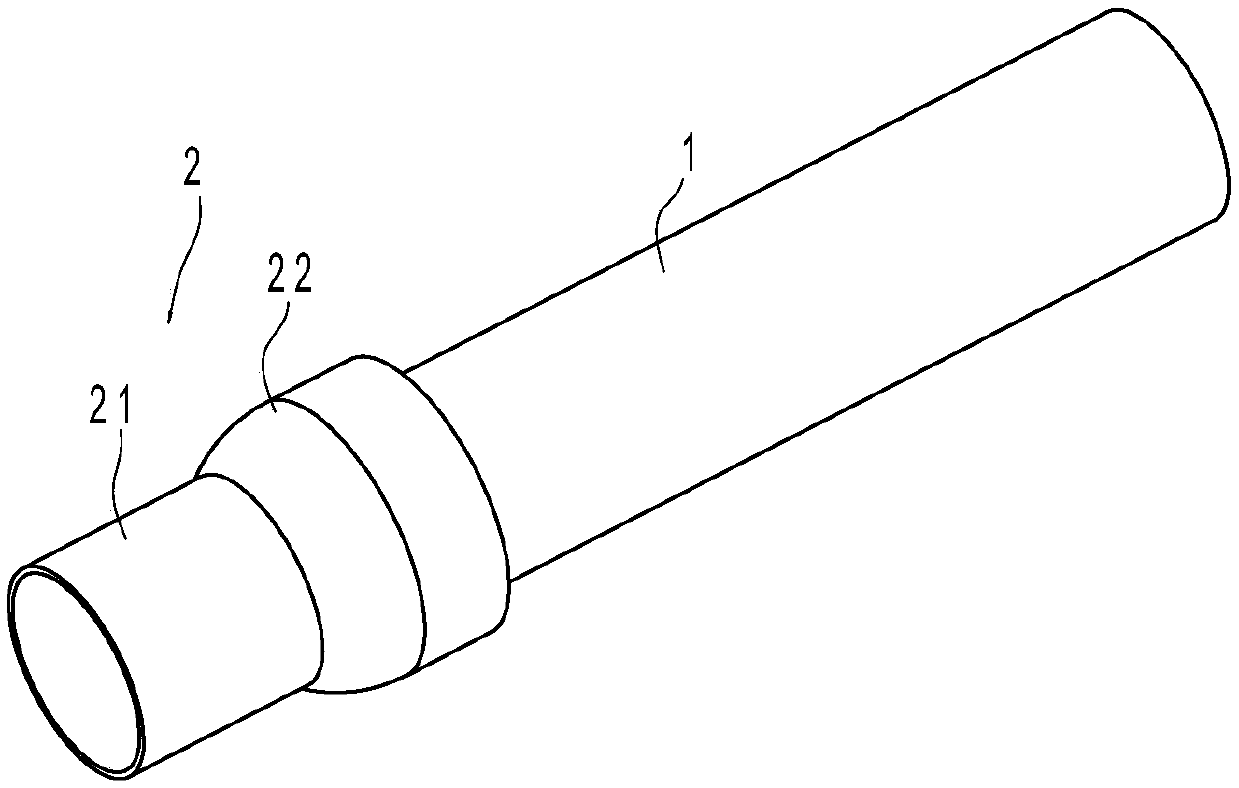

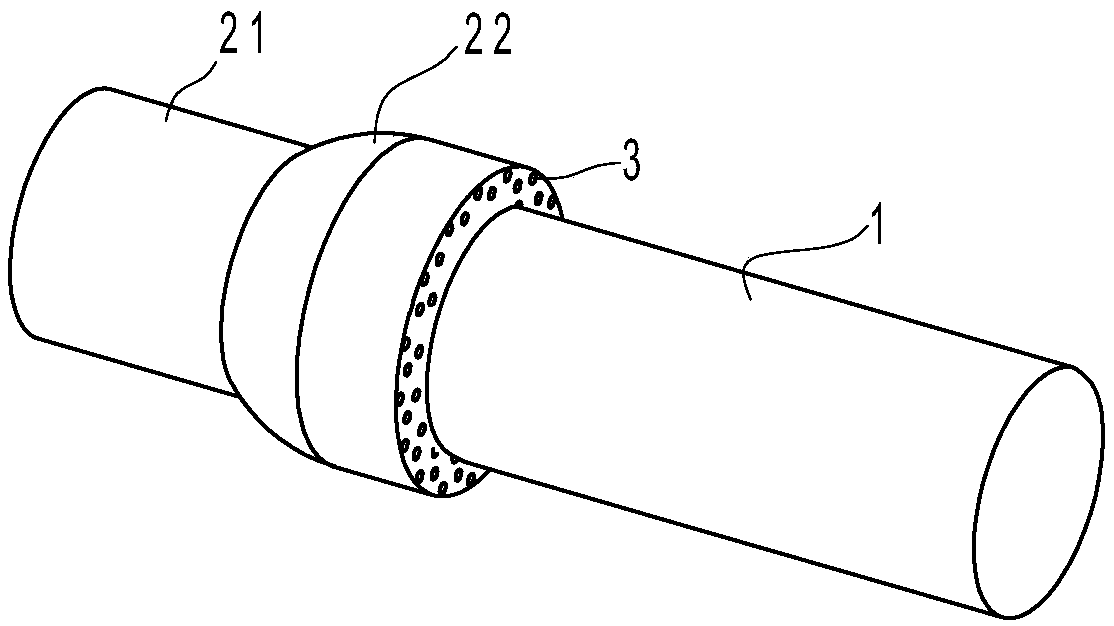

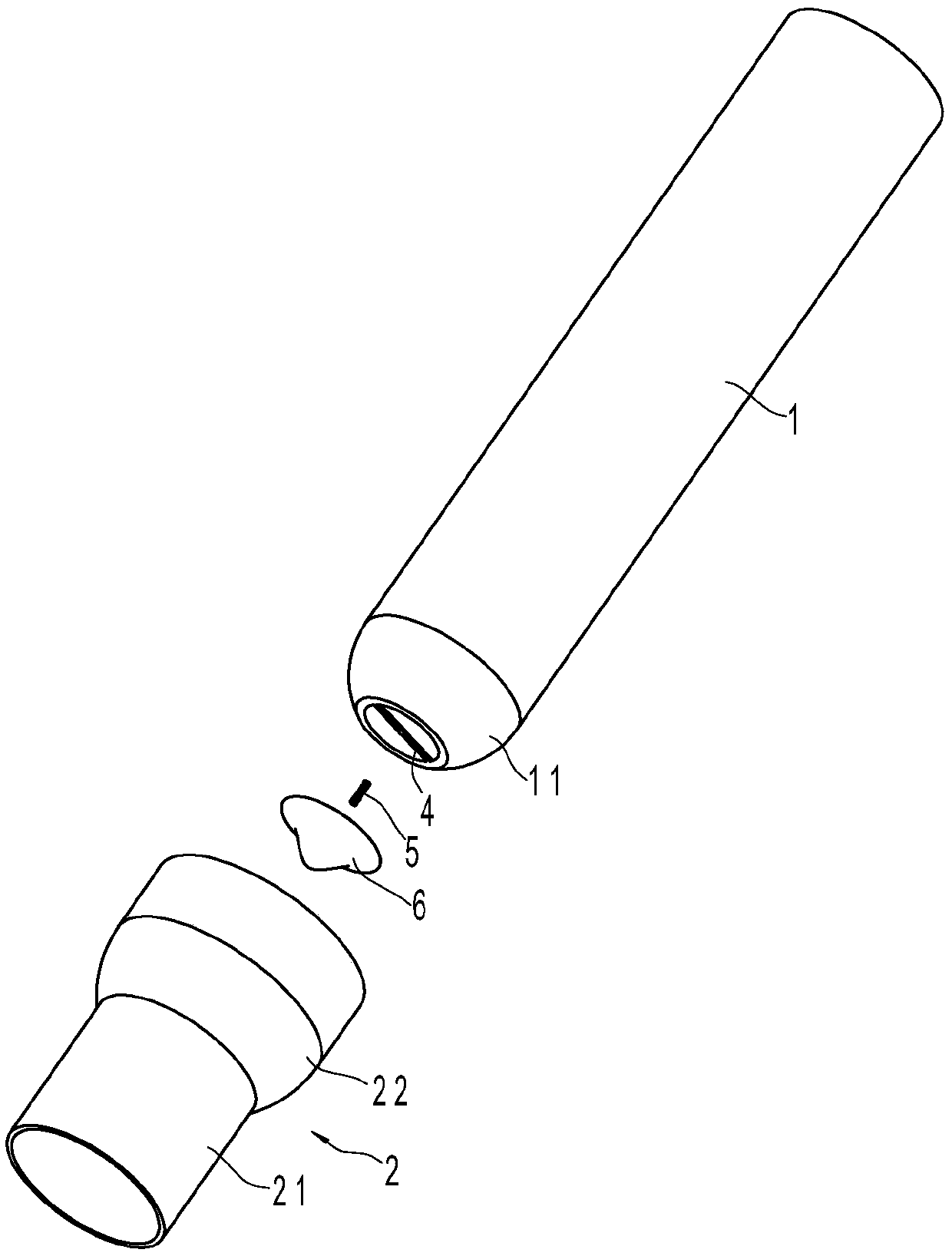

[0022] Such as figure 1 , figure 2 and image 3 As shown, the gas water heater anti-downdraft smoke pipe in this embodiment includes a first smoke pipe 1 , a second smoke pipe 2 socketed with the first smoke pipe 1 , and a flow guide block 6 .

[0023] The second smoke pipe 2 includes a straight section 21 and a flaring section 22 connected to the straight section 21. The gas outlet end of the straight section 21 forms a smoke exhaust passage, and the gas outlet end of the first smoke pipe 1 extends into the flaring section 22. An annular exhaust passage 3 is formed between the outer wall of the smoke pipe 1 and the inner wall of the flaring section 22 .

[0024] The deflector block 6 is elastically arranged on the air outlet end of the first smoke pipe 1 through a spring. When the wind is strong, the flow guide block 6 can compress the sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com